Hopefully these 5 tips will be helpful in making sure you maximise your efficiency.

5. Material Compatibility

Using the correct pump materials of construction are essential if the pump is to have a long life. This is especially so when handling corrosive liquids. Not only the main pump body material, but also the individual parts such as shaft/bearing/mech seal materials must be correctly specified if the pump is to last a long life. Click here for more information, the team at Crest will always carry out this work for you when recommending a pump.

4. Preventative Maintenance

Sometimes, scheduled pump maintenance is overlooked and instead left as reactive maintenance, whereby the pump is repaired if/when it fails. The risk of this strategy is that an entire process could be shut down whilst the pump is offline being repaired. The cost of carrying out a periodic maintenance procedure should be weighed up against the cost of a system shutdown should a pump fail. Also bear in mind a planned maintenance cost is likely to be much cheaper than a repair cost. Please refer to any pumps installation manual which will include recommended maintenance schedules.

3. Operating away from the BEP

Pumps are designed to run at the most efficient point by the manufacturer. If the pump is run too far away from its efficiency point, this can quickly lead to excess recirculation, heat, radial loss, vibration, high seal temperature and vastly lower efficiency. If a pump is to be used for varying duty points, we would recommend our high efficiency AVF range.

2. Improper Piping

Poor piping layout can have a big effect of the pump’s operation and its efficiency. Designs with in-verted “U”s on the suction side can trap air, while designs with a 90 degree bend immediately before the pump can cause turbulence inside the pump. Both could potentially result in suction and cavitation problems for the pump. Inlet pipework should be at least one size bigger than the pump inlet in order to prevent cavitation and allow best efficiency.

1. Do not run the pump dry

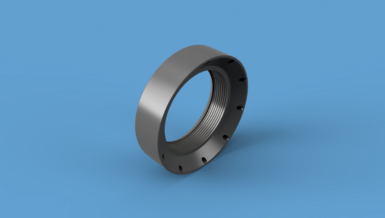

Unfortunately, errors can occur in a process that cause a pump to run dry. For a mechanically sealed pump this can cause an almost immediate failure to the seal. Some mag drive pumps are now available with special material bearings to prevent the onset of damage but allowing any pump to dry run could lead to catastrophic pump failure.

Under normal operating conditions, the pumped liquid acts as lubrication between the rotating and stationary parts, and the heat generated by the rotational action is gently taken away by the circulating liquid. But when a pump is starved of liquid, these moving parts generate heat from friction and as the heat builds up, damage will occur. For a mechanical seal pump, running dry could lead to pump cavitation and therefore seal damage. The mechanical seal could also experience thermal shock and under the right conditions could shatter within 30 seconds. With a mag-drive pump, the bearings and shaft can rise in temperature due to the absence of liquid lubrication and subsequently melt the plastic casing.

With the Crest Assoma mag drive range, a patented auxiliary circulation channel runs between the bearing and the magnet capsule. The pressure difference has a convection effect for cooling both the interior and exterior of the bearing thereby preventing the high temperature build up caused from dry running. The key point of this feature though, is that whilst the design allows for increased cooling, there is no reduction in pump efficiency.

We must point out that there are many ways to run a pump dry, and this design feature is in no way a failsafe method (you should question any pump manufacturer that does make this claim). It depends upon how (e.g. completely closed inlet valve, air lock, foot valve failure etc) and for how long the pump is run dry, as to how long the Crest Assoma Mag Drive range will run without damage. For test reports or further information, please contact us. If a pump is to be installed in an application where the pump is likely to see risks of dry running, then we would always recommend the additional piece of mind with the installation of the PSP1 dry run monitor.