If your pump sounds as though it is pumping marbles, then you probably have a cavitation problem (or marbles have got into your system). Other problems associated with cavitation are excessive vibration that will lead to premature failure of seals and bearings, higher power consumption, and decreased flow and pressure.

How does cavitation occur

If we take water as an example, it vaporizes at atmospheric pressure at 100 degrees C. But the internal design of a pump means that fluids flow at high velocities and the pressure decreases (see Bernoulli’s Law), consequently the liquid will vaporize at a much lower temperature.

There are two types of cavitation:

Suction Cavitation

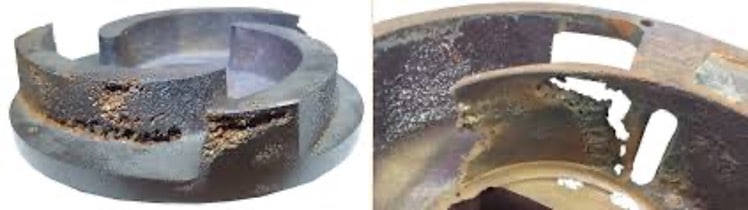

Occurs when a pump is under low pressure or high vacuum conditions. Signs of suction cavitation will be around the eye of the impeller that will have multiple pitting, signs of severe cavitation will make the impeller resemble a sponge. Possible causes of suction cavitation include:

- Pump running too far to the right of its curve

- Blocked suction pipe or strainer

- Bad pipework design including excessively long runs

- High inlet fluid velocity

- Poor suction conditions

Discharge Cavitation

Can occur with very high discharge pressures or when the pump operates at less than 10% of its best efficiency point which causes more recirculation within the pump and high fluid velocity at the outer edge of the impeller. The obvious sign of discharge cavitation is the pitting of the impeller at the outer edges. Causes of discharge cavitation include:

- Pump running too far to the left of its curve

- Blocked discharge pipe or filters

- Poor pipework design

How To Prevent Pump Cavitation

Firstly, you need to identify the cause of the pressure drop. In most cases, the problem can be solved by:

- Simplifying the suction pipework removing as many bends and valves as possible

- Moving the pump closer to the fluid source

- Clean pipework and remove any blockage

- Increasing the diameter of the suction pipework so reducing the inlet velocity

Cavitation is a common problem but damage to impellers can be largely avoided with correct pump sizing, well-designed pipework, and routine maintenance of filters and strainers.