In particular, research has focused on developing fully recyclable plastics that are multi-functional and help to close the materials loop for polyolefin polymer production.

This application note explains how precision control technology – the core business of both Equilibar LLC as well as Equilibar distributor Pressure Control Solutions – enables these researchers to improve fluid control within their research set-up.

Case Study: ILS

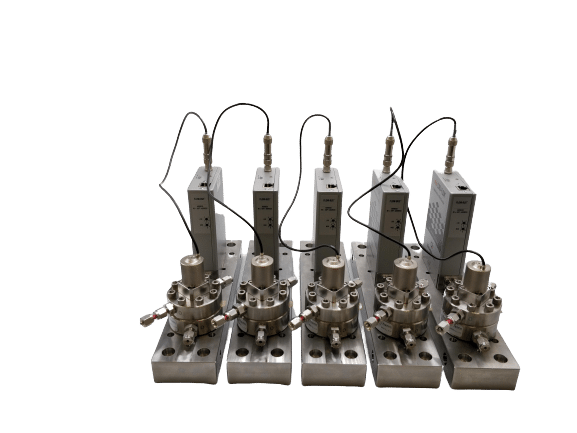

In this context, an interesting example is the project of Integrated Lab Solutions in Germany: ILS has a long-history of designing polyolefins catalyst testing units that are used by researchers and innovators across the world in the global endeavor to improve plastics. In a 2019 project, ILS developed a fully-automated 6-parallel batch polymerization unit capable of doing slurry, gas and bulk polyethylene and polypropylene synthesis. ILS applied Equilibar’s dome-loaded multiple orifice fluid control valve solution to address the challenges related to fluid control.

Flow Control Challenges in Polyolefins Catalysis and Testing

To ensure proper functioning of the ILS testing units, it is necessary to provide quantitative and stable monomer flow control over extremely wide flow and pressure ranges.

A mass flow controller (MFC) alone is just able to provide stable mass flow over a limited pressure range using its integrated electronic flow control valve. When a wider flow range and pressure range comes into play – as is unmistakably the case with polyolefins research – a conventional MFC does not provide the stability and accuracy that is needed to meet the researchers’ system specifications. The MFC will show an instability, primarily due to the flashing issues resulting from dosing liquid gas monomers, such as propylene and 1-butene.

Based on the unique characteristics of the Equilibar control valves for flow control, these challenges were overcome through the use of the patented Equilibar technology. You will see a schematic view of what this solution looks like in the product gallery.

Benefits of including a Dome-Loaded Multiple Orifice Fluid Control Valve

Placing a dome-loaded multiple orifice back pressure regulator (BPR) directly after the thermal or Coriolis MFC enables steady monomer flow control over extremely wide flow and pressure ranges.

By placing this type of BPR downstream of the MFC and upstream of the reactor, the MFC experiences the same upstream and downstream pressure regardless of the pressure fluctuations in the reactor.This setup results in superior monomer flow control over the entire flow range of the high-throughput polyolefin testing unit.

Additionally, the compact design of this specialty BPR allows it to fit into small spaces.

Furthermore, it is easily heated, which allows the system to counteract Joule-Thomson cooling effects that often occur during liquid gas dosing.

Last but certainly not least, it can be made using a variety of materials, allowing an optimal fit with the system it is built into and facilitating resistance to the harshest chemicals. For example, a solution completely made out of Hastelloy is available; full customization as per the process requirements to match the system design and optimize the process outcomes is thus within reach.

To underline just how well Equilibar valves fit together with MFC’s for flow control purposes, we refer to the video of ILS CEO Dr. Anton J. Nagy demonstrating “Fine-Chemicals Batch to Continuous Flow Synthesis Unit” (see video).

Further integration of the dome-loaded multiple orifice fluid control valve

In addition, Pressure Control Solutions developed also a further integrated solution. Armand Bergsma (founder of PCS) explains: “When we offer MFC’s for liquified gasses, we integrate the high-precision proportional valve directly in the cap of an Equilibar back pressure regulator. The proportional valve will only see an inert gas, like pressurized Nitrogen. The dome of the BPR will be pressurized through this proportional valve. A flow restrictor, specifically designed for this purpose, is added to release a constant amount of N2. The single proportional valve is directly actuated by the built-in PID controller in the Coriolis sensor. The PID controller will thus set a perfectly balanced pressure in the dome, creating a stable flow. The flashing of the media takes place downstream of the Equilibar control valve. In some cases, a heating rod is fitted to the Equilibar to compensate for the heat loss.”

A P&ID schematic of what this solution looks like in practice is shown below. Read more about flow control in this blog

About Equilibar

Equilibar is a provider of unique and innovative fluid control solutions based in the USA. The patented fluid control technology is used in a wide array of processes including catalyst, petrochemical, supercritical and other industrial applications. For more information contact an Equilibar application engineer at inquiry@equilibar.com or (+1) 828 650 6590.

About Pressure Control Solutions

Headquartered in the Netherlands, Pressure Control Solutions provides innovative precision control products for a wide array of processes including catalyst, petrochemical, supercritical and pharmaceutical applications. Drawing upon years of experience and specialization, PCS develops systems using top tier products such as dome-loaded multiple orifice regulators from Equilibar and mass flow controllers from Bronkhorst. For more information, contact an application specialist for direct advice at info@pressurecontrolsolutions.nl.

ILS-Integrated Lab Solutions, GmbH is a provider of chemical R&D services and products in Berlin, Germany. Contact their team at sales@integratedlabsolutions.com.