The new TS series is now entering the market as a new sensor generation that surpasses this performance class. Thanks to the integration of the digital communication interface IO-Link, a new modular design, a comprehensive range of performance upgrades, and in particular, the wealth of experience gained from thousands of applications, TS offers unprecedented flexibility and application reliability.

A mini for all

The new generation’s first sensor model is TSM, the mini version of the TS temperature sensor with an 18 mm head diameter. It is available in a food and a pharmaceutical version. A five level configuration, each with a large variety of functional components, results in such a large number of possible combinations that almost any desired combination can be configured to meet all requirements. In addition to this previously unattained flexibility and individuality, the new generation of sensors also features noticeable performance upgrades in the technical specifications. The process temperature range, extended to -200 to +400 °C, the measuring accuracy, improved to < ±0.1 °C, and the increased ambient temperature resistance set new standards. Together with the one-piece design and the all-stainless-steel finish, this promises perfect cleaning results, lasting stability, and long-term application reliability even in the most demanding production environments.

The product range will be completed by the TSB temperature sensor with a 55 mm head diameter and even more extended functions, transmitter variations, and selection options in the next stage.

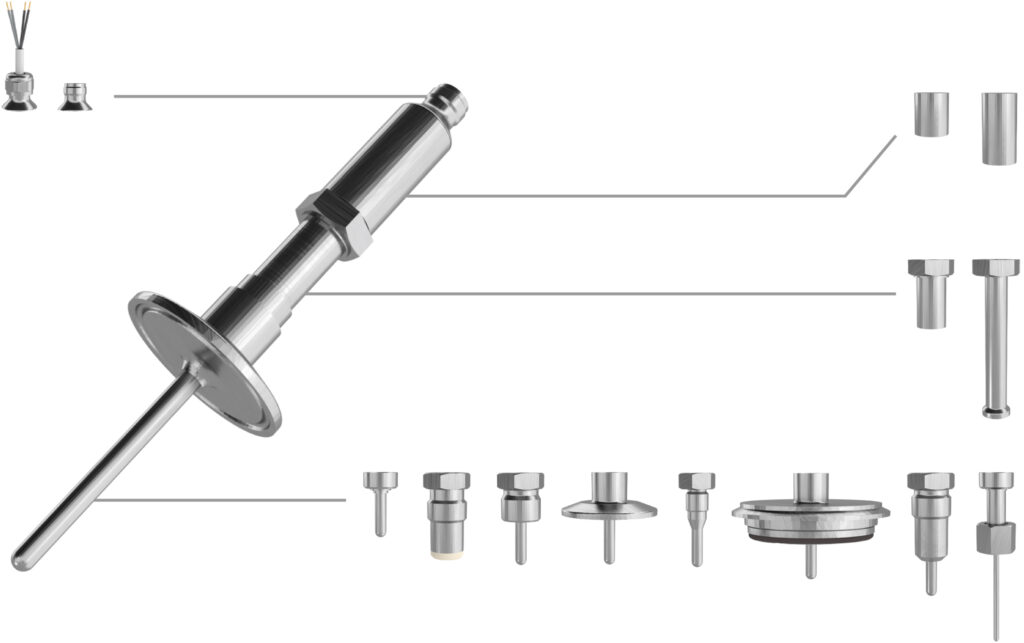

TSM is the mini version of the new, modular temperature sensor generation TS. From the front-flush version to thermowell models and a rod length of up to 2000 mm, TSM offers an unprecedented variety of applications

NEW: Flex-Hybrid technology with IO-Link and 4…20 mA

Digital communication via IO-Link offers significant advantages for reliable process control, especially in an entire plant technology with many measuring points, control, and operating devices. The Anderson-Negele Flex-Hybrid technology combines the best of two worlds: From the sensor, data can be transmitted in digital or analog communication or both technologies in parallel. Sensors can output analog data as usual but can be programmed, parameterized, and adjusted quickly and easily via the digital interface. Instead of “either … or”, Anderson-Negele says “and”.

Flex-Hybrid also gives a whole new meaning to the well-known expression “Plug- and Play”. The flexible communication makes the TS Sensors’ installation and commissioning time and cost-saving. Thanks to individual programming with an IO-Link master, many functions such as changing the measuring range or two-point adjustment of zero and span are child’s play. Sensor replacement is also made easier than ever before thanks to the “Smart Replace Design” with automatic sensor identification, configuration, and parameterization by IO-Link.

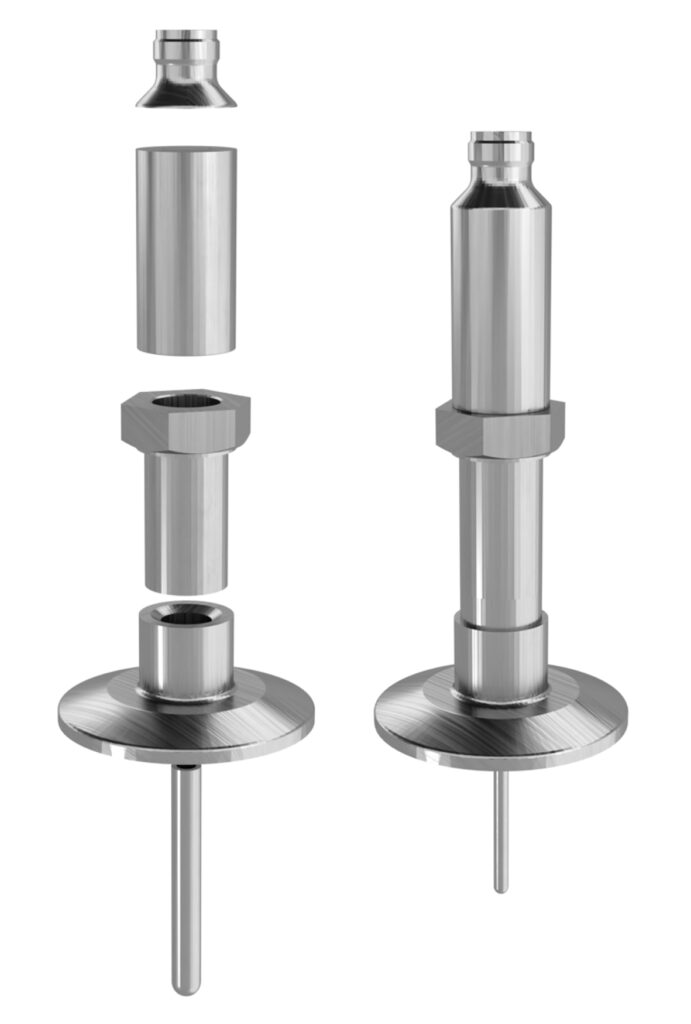

Fully modular, compatible, and flexible

The individual desired sensor can be composed in a few steps according to your needs due to the fully configurable modular concept. Thanks to a large number of options in each of the 5 configuration levels, almost all requirements can be realized. Already at the sensor tip, there is a wide range of selection options for the required process conditions. For example, the flush version is ideal for installation in vessels with agitators or other mechanical devices and enables hygienic pig cleaning in pipes. A process adapter with thermowell, allows the sensor to be removed without opening the process. Sensor tips in various diameters and lengths from 0 to 2000 mm allow particular adaptation to the respective installation conditions and response times of up to t90 ≤ 1.5 s. In the further configuration stages, a large number of screw and clamp connections, different spacers, a headpiece with or without transmitter, and a selection of electrical connections with protection class IP 69K can be selected.

Thanks to the 5-level configuration (sensor tip – process connection – sleeve/spacer – head/transmitter – electrical connection), any desired sensor can be easily assembled to meet individual requirements

As a result, TSM offers a suitable solution for every application:

- For new equipment, the modular design, together with the Flex-Hybrid technology, creates maximum flexibility and sustainability for every application.

- For retrofitting, TSM can therefore replace any TFP mini-sensor in existing systems – with all the additional advantages. The TS series is both mechanically and electrically compatible with the TFP.

- For the replacement of third-party devices, a suitable model is always possible due to the large selection of process adaptations and maximum flexibility in configuration.

Highest standards of quality and performance

The customers’ expectations are undoubtedly enormous with this product upgrade from Anderson-Negele, as for many, the temperature sensors of the TFP series are synonymous with reliability and durability. And yet, the manufacturer has once again managed to set new standards in product quality and performance. An extended process temperature range, from -200°C to +400°C, is now offered as standard. The RTD sensor elements, optionally of the type Pt100 or Pt1000, are entirely embedded in the sensor tip. Even under the most challenging process conditions such as vibrations, pressure surges, or other mechanical loads, they can permanently prove their high measuring accuracy of < ±0.1 °C. The one-piece design, in which all components are manufactured from high-quality stainless steel to create an individual, homogeneous device, also contributes to this.