With more than 2.2 million installed applications and 50 years of experience, time-of-flight (ToF) measurement instruments are an important component of Endress+Hauser’s portfolio.

ToF-devices are used in a wide range of applications, and are a reliable solution even under extreme process conditions, such as high pressure or temperatures and in corrosive or aggressive media. The new generation of Micropilot instruments offers compact design and maximum user-friendliness, as well as application-specific flexibility, to provide solutions for both mobile and stationary plastic tanks.

The storage of liquids plays an important role in many industries. Liquid fertilizers or irrigation systems for agriculture, additives as well as cleaning agents for the food industry or liquefiers for the production of concrete are only a few examples. Usually, plastic tanks are used for this purpose. In order to ensure continuous production and prevent downtime, the liquids must always be available in sufficient quantities. This is where level measurement is used.

As the number of tanks increase, so do the measurement requirements. The fact that plastic tanks are often located at remote sites and are widely dispersed geographically makes the process even more complex. In more than 80% of all production plants, level measurement is done manually. This type of manual monitoring is both time and cost intensive. So, very often, this results in missing stocks only being registered when the tank has already run empty, and the production process has come to a halt. Even increased inventories are in most cases not an alternative due to the storage costs involved. Clearly, a better solution is needed.

Optimized inventory management – simple from the scratch

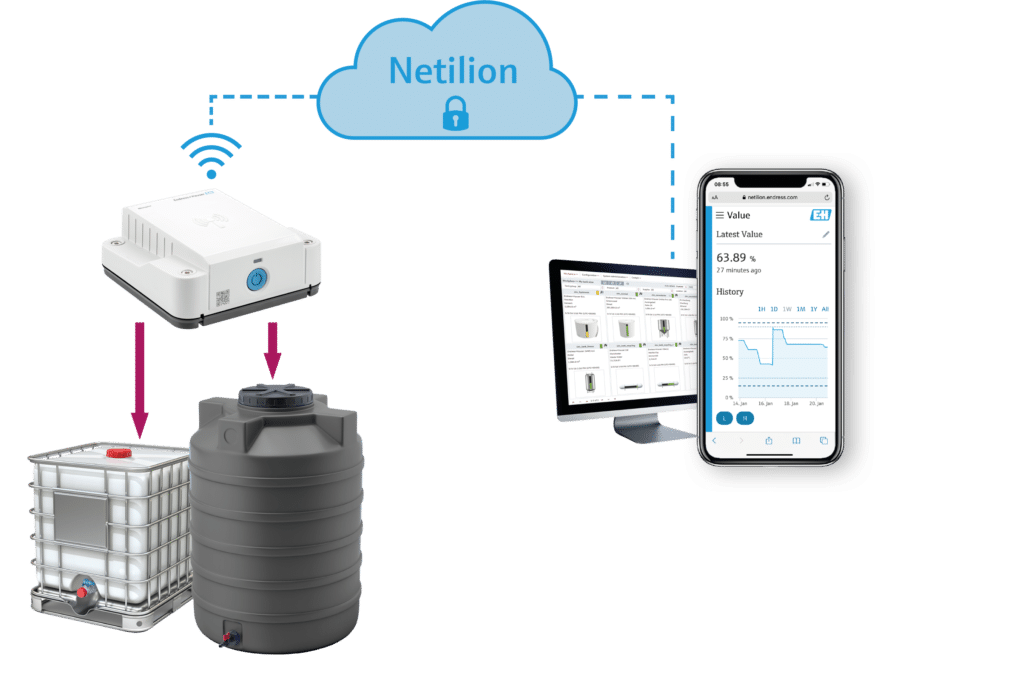

To meet the challenges mentioned above, Endress+Hauser has developed a solution consisting of a level sensor and software. This solution considerably simplifies the management of stocks in stationary and mobile applications. As with conventional devices, the measurement is based on high-frequency radar pulses. These are emitted by an antenna and reflected by the surface of the stored medium. The travel time of the reflected radar pulse is directly proportional to the distance. With a known vessel geometry, the level can be calculated. But the new Micropilot FWR30 offers considerably more.

As the world’s first 80GHz wireless IIoT sensor, it combines high-end technology and user-friendly digital services in one cost-effective device. The continuously recorded measurement data can be accessed at any time and from anywhere via the device’s cloud connection. Communication is made possible by an integrated SIM card.

Installation is simple and can be done in less than three minutes. An integrated battery allows operation without an external power supply, which is an advantage especially at measuring points that are difficult to access or mobile. This compact device is a perfect fit for stackable tanks and enables a plug-and-play solution for flexible and easy installation.

In addition to the measured level, the user receives information on the location of their storage tanks and containers via local mobile phone masts. The first cloud-based radar sensor provides facts where previously only assumptions were possible. It helps users to optimize logistic and storage processes and save valuable time by providing continuous and easy access to inventory information.

Field of application

The Micropilot FWR30 can be used for level measurement and inventory management of mobile and stationary plastic tanks. In addition, the tracking of mobile storage tanks is also possible. The free radiating measuring device covers measuring ranges up to 15 meters (50 feet) and temperatures between -20 °C and 60 °C (-4°F and +140°F). Due to non-contact measurement, the Micropilot FWR30 can be used in all liquid media. It works where other measuring principles cannot be applied due to corrosion, abrasion, viscosity, or toxicity and it can be employed in a variety of industries.

Scalable software applications

Depending on individual requirements, users can choose from a broad portfolio of services. All digital software applications can be used on various end devices such as desktop, tablet or smartphone, and comply with the highest security and data protection requirements.

Netilion Value is a simple digital monitoring solution. The web application provides a dashboard, current values, historical data, alarms, notifications, and a simple user interface. Intelligent sensors can be integrated and connected with just a few clicks.

Netilion Inventory offers a simplified monitoring service to support basic inventory management applications. It comes with add-ons like volume calculation or forecast and it determines the free storage capacity. This extended service provides the user with a clear overview of the status of tanks, silos, and containers.

SupplyCare Hosting is a comprehensive inventory management solution that provides users with event history, a customizable overview, and the evaluation of key performance indicators such as average stock, efficiency, or turnover rate. User management is simplified with role-based, adaptable access rights-allowing for the integration of suppliers, customers, and partners with the software. SupplyCare Hosting also provides user-friendly demand planning and can be synchronized with all common ERP systems.

The advantages of the new Micropilot FWR30 at a glance:

- Reliable and cost-efficient level measurement with 80 GHz radar technology

- Full transparency for storage and transport of liquids

- Simplified solution from procurement to operation

- Access to relevant information from anywhere and at any time

- Scalable software applications from measure point monitoring to inventory management

- Battery powered sensor with mobile communication

- Certified cloud service meeting the highest security and data protection requirements