DESCRIPTION :

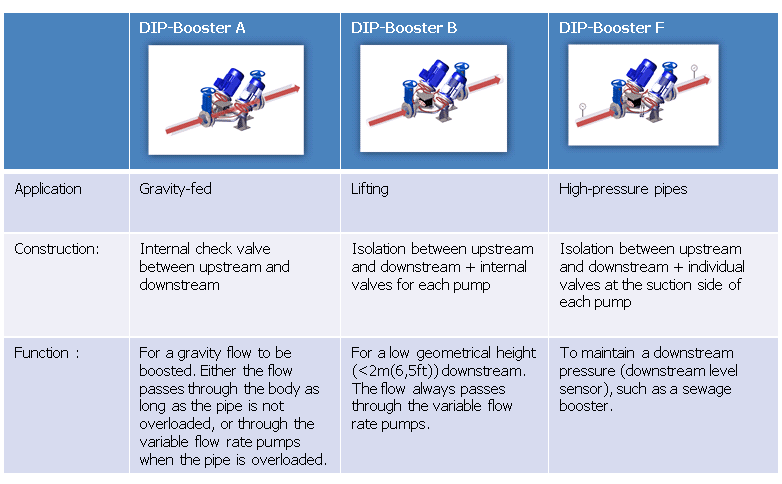

Derived from the high range of wastewater Direct In-line Pumping systems DIP Systeme®, there are 3 main types of DIP-Booster : Gravity-fed DIP-Booster (type A), Lifting DIP-Booster (type B), DIP-Booster for high pressure pipes (type F).

They are all custom-made according to project specifications and manufactured in France.

TECHNICAL DATA :

- Available with several different types and size of motors (IP67 or IP68).

- Of modular and reproducible construction, made of AISI 304L or 316L stainless steel.

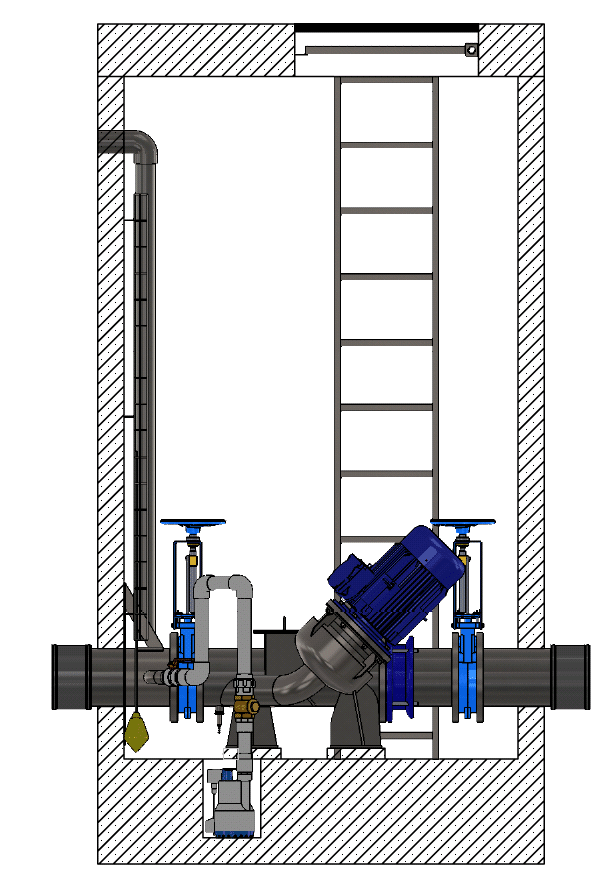

- Fits into the profile of the pipe and is inserted in a simple chamber or in a prefabricated version in a BOOSTINOX.

- Available models from 8’’ to 40’’ diameters (DN200 to DN1200)

- Intelligence built into frequency converters for intelligent self-adaptive operation.

- Two knife gate valves with stainless steel gates ensure the upstream and downstream isolation of the pumping system.

The DIP-Booster® solution that can change everything without replacing everything

APPLICATIONS :

- Pipes with insufficient slope (type A)

- Pipes undergoing periodic backups (type A)

- Accelerated in-line wastewater circulation (type B)

- Flow increase for a gravity-fed line of 8’’ to 40’’ diameters (type A)

- Savings on pipe diameters (type A, B, F)

- Where increased scouring is needed (type A, B, F)

- Sewage overpressure (type F)

- Reverse slope pipe (type B)

- Gravity discharge in case of downstream flooding (type B)

REFERENCES :

DIP Booster 100 B – 4kW installed in a Boostinox at the international airport of Washington-Dulles (application : pipe with insufficient slope reducing its capacity)

DIP Booster 100B -3kW of the water treatment plant of Achères (France) (application : to « boostly » pump centrifugate water (clarified liquid) produced by two mobile centrifuges of 2.5 and 3.5 T MS/h)