After establishing a strong client base in the UK, the team set its sights on Europe, particularly Rotterdam, as it offered new opportunities to expand the company’s offering.

Since then, the company, based in Essex, UK, has secured significant contracts with high-profile storage operators globally and, following feedback from clients, is now investing more in researching new innovations as new challenges emerge, our services http://lasersurveying.com/services/

For example, the company is currently researching how drones can be utilised alongside its field laser scanners.

Colin Pittman (Director) explains that the addition of a drone along with its 3D laser scanning operation could prove to be invaluable.

‘Although drones cannot achieve the degree of accuracy required for pipework modelling, we have looking into their use with overall site scanning for information purposes.

‘This has been particularly useful where ALS consider client sites on the other side of the world. The up-to-date data collected by a drone can be invaluable in assessing the overall number of field scans required to cover the site.’

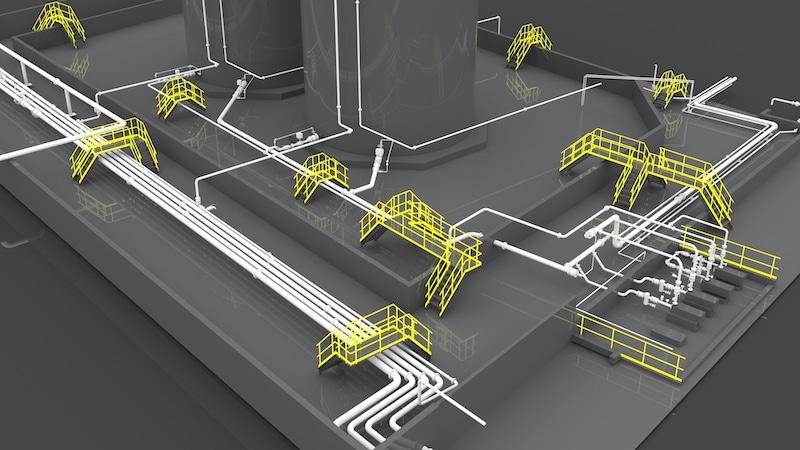

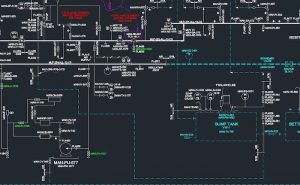

Another innovation being developed by the company is the integration of client’s assets using both the developed 3D model alongside intelligent process and instrumentation diagrams (P&IDs).

‘Advanced 3D Laser Solutions are particularly suited given the rich background knowledge achieved from working within broad spectrum of process industries and storage terminals across the globe.

We believe we are unique in the ability of our surveyors to operate multiple instruments when completing a 3D laser scanning operation on a client site.

‘Typical fuels and/of chemical storage terminals can require upwards of a thousand scans to cover all subject matter intended for modelling.

‘With a single scanning instrument working outside we can, after allowing for site permits and battery changes, expect to complete 30-35 units of scanning. With our experienced surveyors working with multiple instruments we can survey a client terminal using say five instruments, completing up to 175 units of scanning a day.

‘The result is less time spent on a client’s site and efficient use of client capital in having their survey completed by Advanced 3D Laser Solutions.’

P&ID intelligence

Intelligence in P&IDs is now being considered as a useable gateway for clients to access not only asset information but inspection records and record drawings. Along with the 3D process model, there is now the ability to link with the client operating systems, updating all connected records from a single source.

Legislative demands

Legislative requirements for the terminal operator continue to put demands on the maintenance of compliance documentation, records and drawings.

Keeping these records up-to-date and accessible has historically, and quite naturally, resulted in an increasing administrative overhead. Information regarding a single asset will inevitably result in duplication of asset details across many documents, each requiring update when a change occurs.

Typically, an asset management system will allocate a unique number to an asset. Identifying this unique number and establishing its correct location within an operating site can be labour intensive. This is where having an intelligent P&ID and 3D process model will speed up the correct identification of an asset.

Linking of the asset records to an easy to interpret viewing portal reduces time spent and therefore administration costs. Having established a more efficient viewing portal, linking this through Advanced 3D’s associates software to the client’s existing operating and asset management systems means that clients can update all linked documents from one source.

Without loss of historical data, if an asset is replaced the new information can be updated for instance through the intelligent P&ID and all connected records will automatically update. The savings to a terminal operator are significant as less administrative input is necessary to maintain compliance records using the single source file to update.

Advanced 3D Laser Solutions are already engaged by a major independent storage company now looking to take advantage of this significant cost saving technology.

Building on success

The company’s commitment to improving its software enrichments has resulted in contracts across the globe as the concept of 3D laser scanning continues to appeal.

Our success has been achieved by our commitment to researching both new, and in improving, software enrichments and in listening to our clients’ needs. As a result, we offer cost-effective solutions that enhance our clients’ businesses.

‘Our vision is to continually invest in our people. Innovation is key to our growth and the solutions we can offer our clients.

‘We are not just building a business, we are building a brand that is recognised globally.

‘We embrace the challenges that the future holds with an entrepreneurial spirit that will keep us at the forefront of this ever-challenging industry.’

For more information

Call Colin Pittman +44 (0)7435 760153 email colin@lasersurveying.com or

Call Rene van Eerten +31 61074 1994 email rene@induzzsolutions.nl