In the United States alone corrosion costs the industry more than a billion dollars a year.

What is pipeline corrosion?

Pipeline corrosion is a natural occurrence. Pipe material and essential properties deteriorate over time. Corrosion occurs due to electrochemical reactions of pipeline materials with their environment. You can find corrosion on the inside as well as outside surfaces. Like any other natural hazard, pipeline corrosion can cause a life-threatening failure. It can also cause expensive damage to the pipeline and related systems.

Cathodic protection against corrosion

You can shield steel piping with cathodic protection to prevent corrosion. This technique reduces the corrosion of the metal surface. It does so by making the surface the cathode of an electrochemical cell. This cathodic protection system works by applying a small current to the pipeline. The technicians apply the current to the pipelines via units known as transformer-rectifiers, which convert AC electricity into DC. The plant uses this electricity to lower the ‘energy’ of the pipeline.

The impressed cathodic protection shields some piping against corrosion. This type needs a non-conductive barrier between the process piping and the instrument. The barrier protects it from the effects of electrical current. This measure, in turn, protects expensive electronics.

Dielectric isolation kit protects the instrument

AS-Schneider recommends using a dielectric isolation kit as a non-conductive barrier. This kit is for installation on the inlet flange connection of the manifold. It goes between the stabilized connector and the manifold.

We have designed dielectric isolation kits to maintain the integrity of the pipeline. They also ensure the reliability of the piping system through safety and corrosion protection. Dielectric isolation kits provide an effective seal and electrical isolation of flanges. By eliminating metal to metal contact, we halt static current. In this way, we prevent electronic harm to the instrument.

Challenge getting reliable dielectric isolation kits

If we look back a few years, when we were developing the dielectric isolation kit, there was a big challenge. That challenge was, how to get a reliable, leak-tight connection for 6000 psi (414 bar). The connection had to be without an encapsulated gasket. We also had to tighten the bolting against a non-conductive soft plastic material. But we never back down from a challenge: “The challenge is one of the reasons why developing products is so much fun and is always exciting for me” explained Markus Häffner, Director of Design and Development, AS-Schneider.

Requirements for dielectric isolation kit

In the beginning, this development did not look like a big challenge. However, in the end, we had to make many tests to have a safe and reliable product.

Why? The task seemed to be quite easy, but so often the devil is in the details. In our case, the requirements were:

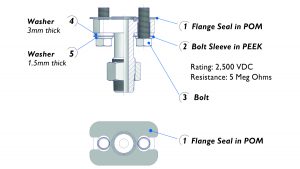

- Pressure of 6.000 psi (414 bar)

- Rating: 2,500 VDC / Resistance: 5 Meg Ohms

- Temperature: 176°F (80°C)

The developing process

For a leak-tight sealing system up to 6000 psi (414 bar), we had to tighten the bolts with a defined torque. The plastic also had to absorb the forces resulting from this torque. Additionally, the sleeves become very soft when heated to a temperature of 176 °F (80 °C) and tend to creep. This creeping causes the bolt tension and thus the compression of the seal ring to decrease. At this point, leakage can occur.

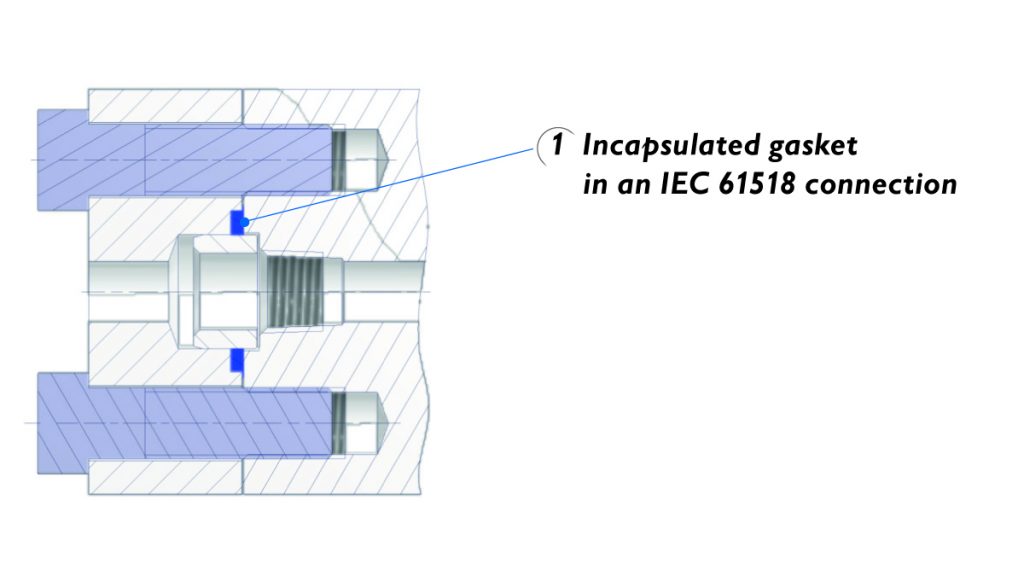

To achieve our goal, we conducted detailed investigations of the gasket geometry, extensive testing of the composition of different plastic materials. We even tested different contents of glass fiber for our reinforced plastics. The below picture shows the AS-Schneider dielectric isolation kit used in many installations.

Part of the direct mount system

The dielectric isolation kit is an essential part of our Direct Mount System, as it enables close coupling of Electronic Flow Measurement devices to an orifice fitting. AS-Schneider designed these systems for close coupling in a safe, efficient manner. They cut or reduce the effects of Gauge Line Error.

Pulsation creates Gauge Line Errors

Pipeline Gas Compressor Research Council and Southwest Research ran a recent study. They looked at pulsation created by regulators and flow control valves. They also researched compressors and some piping configurations. They found that pulsation may create undesirable levels of Square Root Error. It also creates Gauge Line Error. Pulsation at the orifice meter is a significant source of lost natural gas. These errors cause huge economic gains or losses. They affect both the buyer and seller in a natural gas pipeline system.

The research made some conclusions about transmitters and electronic flow measurement devices. It found they should use equal length, large orifice constant diameter gauge lines. They should also use multi-turn valves to protect electronics from pressure spikes. These should be close coupled to the orifice taps. The SDMS system minimizes or eliminates Gauge Line Error, and it’s easy to install. Also, it’s available in both vertical and horizontal to vertical configurations.

Leak free measurement installation

We, at AS-Schneider, have developed the so-called Schneider DirectMount System – SDMS for short. By using the SDMS, you reduce the installation costs significantly. There’s no need to manufacture and install tube runs, fittings, and expensive pipe stands. SDMS reduces potential leak points associated with NPT connection. Schneider DirectMount Systems also provide a safe, compact, leak-free measurement installation. The internal porting promotes self-draining of condensates and liquids to reduce freezing issues. It uses the IEC 61518 system, which meets the recommendations of the American Petroleum Institute. The Gas Processors Association and the American Gas Association have also approved it.