Introduced following a major investment in 2018, the Bredel APEX pumps are providing optimum performance at the company’s plant in Quzhou, some 200km southwest of Shanghai.

Huayou Cobalt was founded in 2002 to specialize in the R&D and production of new energy lithium-ion battery materials and new cobalt materials. Company products include battery-grade cobalt tetroxide and high-purity battery-grade cobalt sulfate. To help support its growth, group company Quzhou Huayou New Technology invested CNY 6.4 billion (approximately £700m) two years ago, a move that would see it become the largest lithium battery materials manufacturer in China.

Rising demand

Global battery-making demand is rising rapidly, with some projections predicting that lithium-ion energy storage requirements will increase tenfold by 2040. Much of this extra demand will be placed on China, where some estimates suggest up to 73% of global lithium-ion battery production is already located.

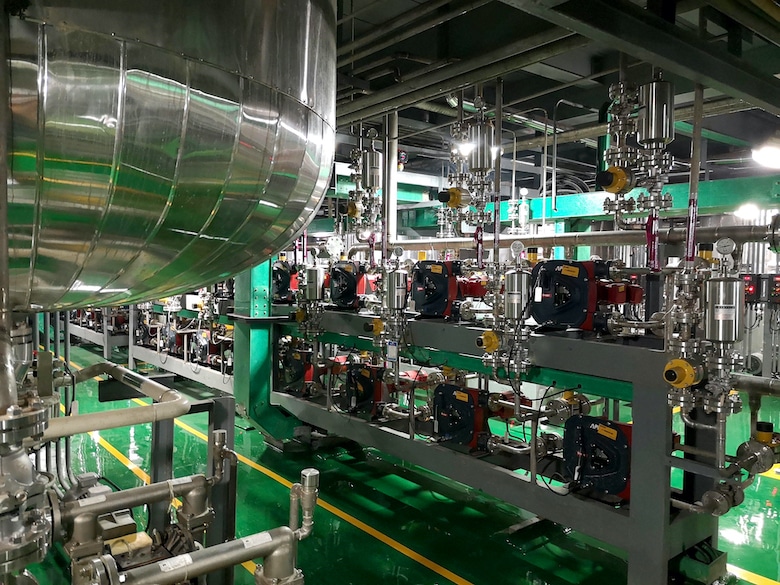

Quzhou Huayou New Technology uses its various Bredel APEX pumps to transfer a number of different liquid chemicals from raw material tanks to reaction tanks. For instance, the plant’s APEX10 (10 mm inner diameter element), which is the smallest pump in the Bredel APEX range, is handling ammonium hydroxide at relatively low flows.

The larger pumps on site, such as two APEX28 units, are transferring nickel sulfate and sodium hydroxide, while the largest pump in the Bredel APEX range – the APEX35 – is being deployed at Quzhou Huayou New Technology to transfer liquid supernatant. The supernatant is the resulting fluid after a mixture of liquid and solid has been left to settle out, or centrifuged to provide separation.

Decisive factor

All of the pumps at Quzhou run with a maximum discharge pressure of 3 bar, which is ideal for the APEX series and was a key factor in the purchase decision over the higher pressure Bredel range.

With their seal-less, valve-less design, APEX pumps are engineered for a more competitive price/performance ratio in comparison with high-pressure hose pumps. APEX pumps are designed to suit all dosing, metering, and transfer applications with unmatched flow stability from 2.8-6200 l/hr.

As a new set-up project, the Watson-Marlow team was engaged at an early stage, specifying the optimum fluid-handling solutions to suit the various applications on site. Of course, this task not only involved pumps but the corresponding precision-machined hose elements.

Correct hose element selection is critical to ensure pump performance, durability, and efficiency. Bredel composite reinforced hoses are constructed from high-quality compounded rubbers fortified with four individual layers of braided nylon. Inner and outer layers are extruded and, after construction, machined to ensure critical tolerances are maintained.

At Quzhou, NR (natural rubber) hoses were identified for the APEX10 and APEX35 applications, while EPDM hoses are used with the APEX28 pumps.

Innovative products

Upon placing the order for the Bredel APEX pumps and hoses from WMFTG, a representative of Quzhou Huayou New Technology said: “This order is confirmation of outstanding enterprise, innovative products, and an excellent team.”

The pumps are installed on several process lines that operate on a batch production basis. When a line is running, the pumps will typically operate for 24 hours over a period of 7-10 days. Once a batch has been completed, the production line will stop until the next batch is required.

WMFTG now has many Bredel pumps serving lithium-ion battery applications in China, helping manufacturers meet ever-more demanding production schedules.