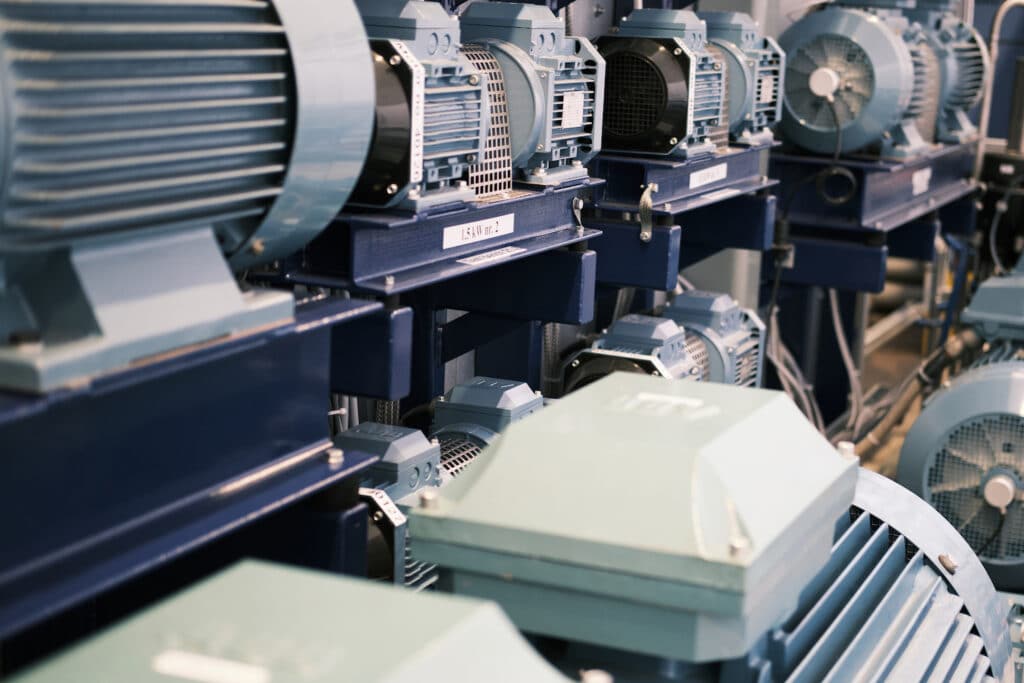

New drive capabilities for water and wastewater applications

Today, more than 20% of all-electric motors are driven by variable speed drives. The main reason for using drives is the reduction of energy use. However, there are also other reasons for employing drives in water and wastewater applications, such as process control (keeping constant water pressure, thus avoiding leakage caused by high pressure), avoiding water hammer, or optimized well exploitation.

Since the introduction of microprocessors to control the drives, additional functionality has been added to the original function – which is that of a powerful processor. For example, drives are able to perform pump de-ragging in wastewater applications, they are able to control several pumps in a cascade system in water pumping applications, or can by-pass certain frequencies to avoid resonances.

The advance of Industry 4.0 has given an additional boost to these additional functions. As Industry 4.0 deals with information and networking, we start using the drives as smart and networked sensors.

The drive as a sensor

In variable speed drive applications, the availability of microprocessors in the drive and bus communication options, combined with current and voltage sensors opens new opportunities. Moreover, additional sensors (such as vibration and pressure sensors) can be connected to the drive at almost no cost. This allows the drive to be used as a smart sensor for condition monitoring. The available information offers various use cases, e.g. system optimization, energy efficiency optimization, and condition-based maintenance. The next section will explore some examples of sensor integration and condition-based maintenance.

Embedded condition-based monitoring

Condition monitoring is a technique to monitor the health of equipment in service. For this purpose, key parameters need to be selected as indicators for developing faults. The equipment condition typically degrades over time. The point of functional failure is when the equipment fails to provide the intended function. The idea of condition-based maintenance is to detect the potential failure before the actual failure occurs. In this case, maintenance actions can be planned before functional failure, with advantages such as reduction of downtime, elimination of unexpected production stops, maintenance optimization, reduction of spare part stock, and others.

Condition monitoring operates on three principles:

- Vibration level monitoring. Having a suitable vibration transmitter mounted and connected to the drive, the drive can offer advanced monitoring by correlating the transmitter signal with drive-internal signals, e.g. speed, or other signals that are relevant for the application. The drive can detect faults early Maintenance can be prepared and scheduled in advance while the system can continue operation until the next possible maintenance break.

- Electrical signature analysis. The condition of the motor and application can also be monitored through electrical signature analysis. This technique has been under research for many years. The early studies have addressed direct online machines, and later variable speed drive applications have been investigated too [5,6,7]. With the available processing power and memory in today’s drives, these techniques can be integrated into products as product features now. Fault condition indicators can be extracted from the motor currents and voltage signals. Frequency components of currents and voltages can be related to motor or application faults, e.g. shaft misalignment or stator winding faults.

- Load monitoring in pumps. During monitoring the drive can detect over-load and under-load conditions, which can be caused in pump applications by faults such as: fouling, sanding, broken impeller, wear out or other. In applications where the load depends on the motor speed, the torque estimation can be used for determining over-load and under-load deviations. During baseline the drive “learns” the normal distribution of the load, or the load envelope.

Conclusions

Condition monitoring can be used for implementing condition-based maintenance – which is an evolution from corrective and preventive maintenance. But condition monitoring relies on sensor data; and installing additional sensors can be expensive. However, if variable speed drives are already used in the pumping application, they are a valuable source of data that can be used for condition monitoring, saving unnecessary expense.