A Review of the Sugar Refining Process Challenges

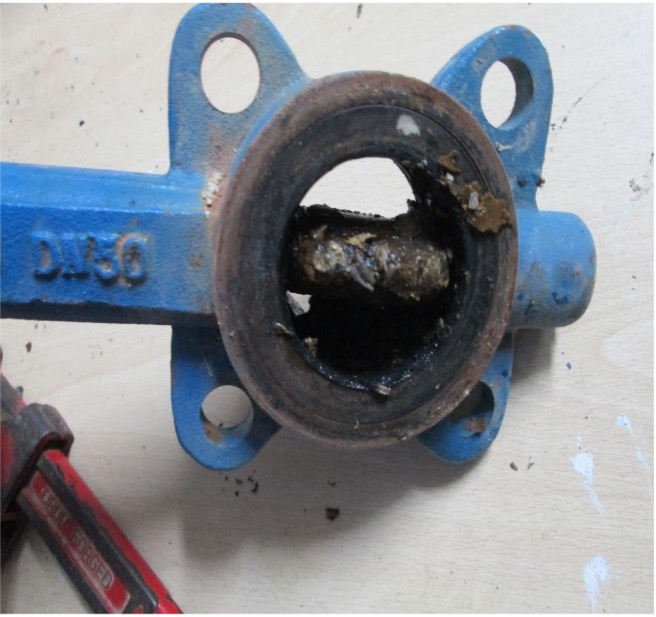

- Abrasion: this physical phenomenon is present in all the plants, due to the number of suspended solids in the Raw Juice, after the extractions of Juice in the primary mills.

- During juice extraction, the raw juice contains a significant number of suspended solids, leading to high levels of abrasion throughout the system. This abrasive medium can degrade the valve’s internal components, including the disc, seat, and in some cases, the valve body. Valves deployed in such environments must possess enhanced durability to minimize wear and extend operational life.

- Corrosion: There are different ranges of pH during the process of Raw Juice until it becomes Crystal Sugar. The sugar refining process involves a dynamic range of pH levels, particularly during the treatment of raw juice, which begins in an acidic state and is neutralized later. Valves must be engineered to withstand both acidic and neutral conditions without compromising performance or integrity, making corrosion-resistant materials crucial.

- Vacuum: A significant portion of the heating and evaporation process (such as the concentration of syrup) occurs under vacuum conditions. Valves in these systems must maintain excellent sealing capability and structural integrity under vacuum, ensuring no loss of seal or degradation in performance.

- High Temperature: As part of the process, it is necessary to remove all the water added at the very first stages of washing and cleaning. The heating is done slowly; gradually removing excess water requires gradual and sustained heating. Valves used in these high-temperature operations must be able to tolerate extended exposure to elevated temperatures without loss of mechanical properties or sealing efficiency.

MaxSeal Performance Series 51/52 – Ideal for Sugar Mills

The MaxSeal Performance Series 51/52 is designed to meet the rigorous demands of sugar refining, offering unmatched performance in handling abrasive media, corrosive environments, vacuum conditions, and high temperatures. Key features include:

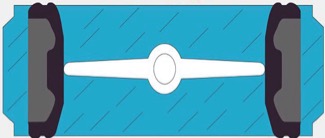

- Body: Constructed from ductile iron with an epoxy coating for superior mechanical strength. The body is designed to handle “dead-end service” applications. Its rugged construction ensures reliable operation even in the most demanding environments.

- Stem: The two-piece blowout-proof stem, fabricated from stainless steel, is designed for easy assembly and maintenance. The ISO mount pattern eliminates the need for pins in the flow area, enhancing reliability and reducing potential points of failure.

- Disc: The disc is engineered for high-flow applications, minimizing restrictions while optimizing fluid control. Available in various materials, including nylon-coated, stainless steel and ductile iron, the disc provides versatility and durability for diverse operational requirements.

- Seat: Max-Seal’s cartridge seat, featuring phenolic backing and peroxide-cured EPDM, offers superior sealing performance. The seat can be customized with alternative materials such as Buna-N, Viton, or Teflon to suit specific process needs. Notably, the seat includes a triple O-ring seal in both stem areas, providing enhanced sealing performance in vacuum conditions and resistance to high abrasion.

Comparative Analysis: MaxSeal vs. Competitor Designs

The MaxSeal design outperforms the competition, particularly those using a collapsible dovetail seat design.

Key advantages of the MaxSeal cartridge seat include:

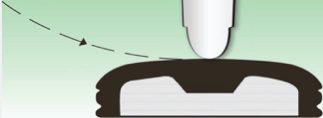

- Cartridge Seat Construction: Unlike the dovetail seat, which can deform or displace during installation, the Max Seal seat is a rigid, unified component. Its elastomer is bonded to a hard phenolic or metal backing, preventing seat movement and distortion under vacuum or high-pressure conditions. This design ensures no loose linings that can swell, tear, or become distorted during operation, offering superior durability and consistent performance.

- Vacuum Service: The Max Seal seat is designed for full vacuum applications, with no risk of deformation, tearing, or bunching, which are common issues in competitors’ dovetail designs. This makes it ideal for the sugar mill’s vacuum-intensive processes, such as evaporation and concentration.

- Abrasion Resistance: The thicker seat profile provides enhanced resistance to abrasive media, reducing wear and extending the life of the valve. This feature is critical in sugar mills, where valves are frequently exposed to solid-laden fluids.

One of the applications where MAX SEAL has proven success is “Vacuum Pan Discharge”, it is an application where all the properties are tested. We have valves working for 4 to 5 years, cycling at least 5 or 6 times a day, with working seasons of 6 months.

Application Areas in Sugar Mills

The MaxSeal Performance Series is suited for the following critical applications within sugar mills:

- Juice Extraction

- Evaporation and Syrup Concentration

- Crystallization

- Centrifugation

- Cane juice scale weight tanks This is a high-cycle operation, and any leakage from failing butterfly valves becomes a significant issue for users. Since cane growers are paid based on the juice processed, any leaks can lead to dissatisfaction, as producers may feel they are being short-changed and that their delivered product is not being weighed properly.

- General Piping and Fluid Distribution

For processes involving temperatures above 300°F, Max-Seal offers a high-performance double-offset or triple-offset butterfly valve solution. The TRI-MAX Double Offset Butterfly Valve features a no-screw floating design, ensuring positive bi-directional shut-off with zero leakage.

Conclusion

Butterfly valves, such as the Max-Seal Performance Series 51/52, are indispensable for maintaining the efficiency and reliability of sugar refining processes. Their robust construction, advanced seat technology, and versatile material options make them the optimal choice for overcoming the challenging conditions found in sugar mills. Max-Seal valves offer a long-lasting, cost-effective solution for controlling fluid flow, ensuring consistent production of high-quality sugar.