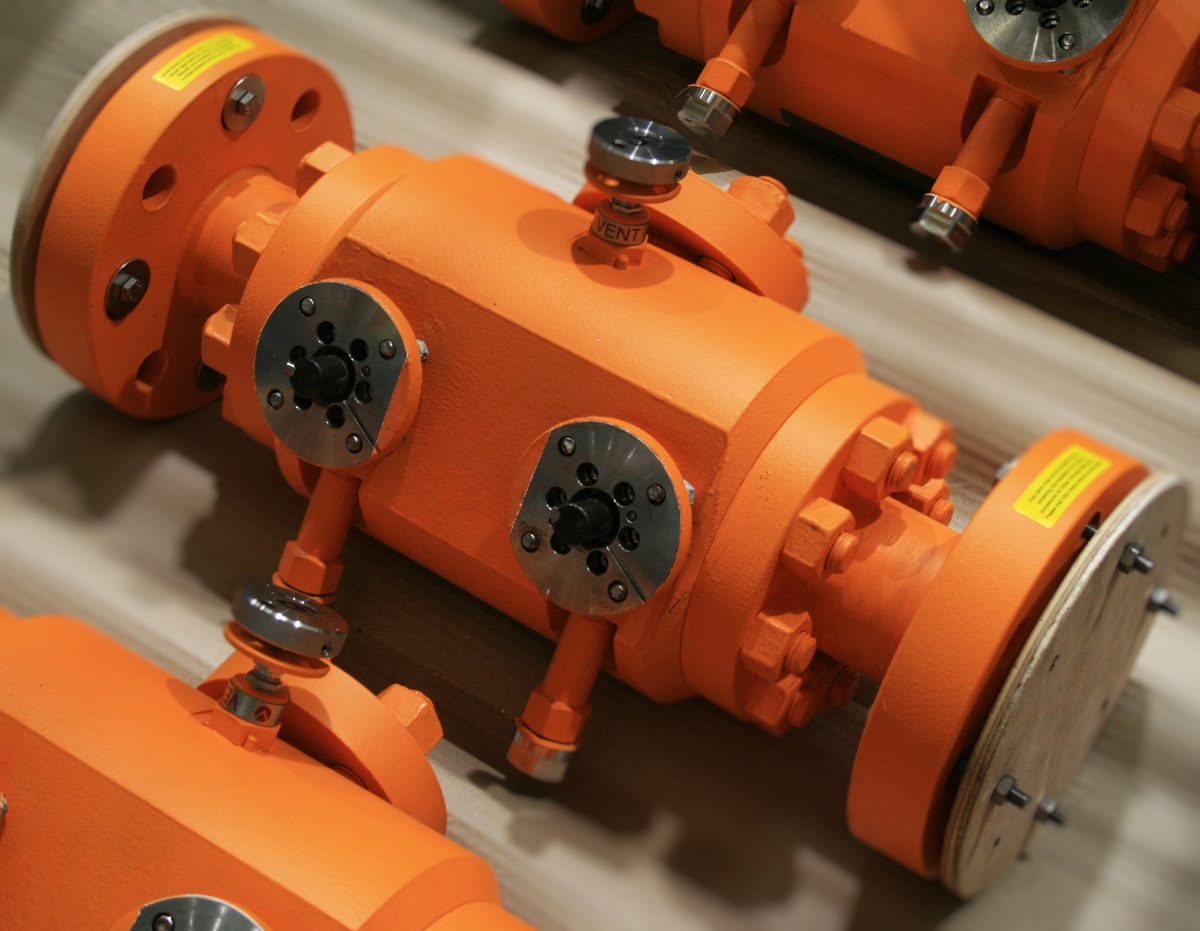

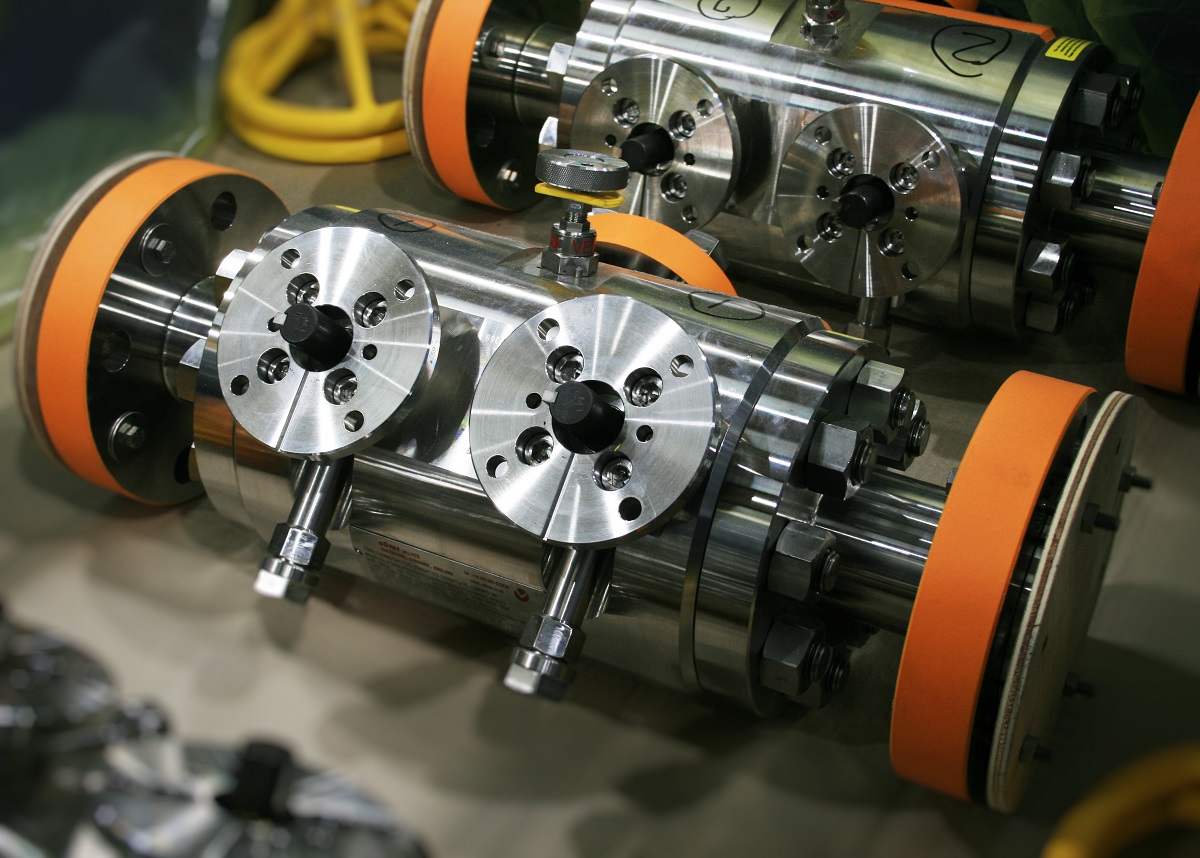

The paint shop is fully equipped with the latest shot blast and spray paint booths, curing rooms, and has the capacity of 100’s of valves per day. A wide range of stove cured wet paint systems are available to choose from, they include: zinc rich epoxies, inorganic zinc silicates, epoxy mastics, high temperature silicone, epoxy phenolics, acrylics, and polyurethanes. Also offered are specialist painting techniques such as Thermally Sprayed Aluminium – this is an application of molten metal, usually aluminium, which gives a very high corrosion resistance for use at very high operating temperatures. NACE inspection is available on request and supplied with full paint certification and reports.

To get a high standard paint finish, the valves complete a thorough process, that include, degreasing and masking the valve to prevent ingress of shot in the bore, shot blasting, priming, intermediate coats applied, and then finished with a top coat in your chosen RAL or BS colours. Identification markings painted on the valve are always an option too and these can be fully customised to include application of a multi-layer painting process to conform to your own specification.

For your next custom painted valves, contact Oliver Twinsafe Valves on 01565 632 636, email sales@valves.co.uk