PCM designs transfer, dosing, mixing, filling, and injection pumping solutions and processing systems for the food industry, as well as the cosmetics and pharmaceutical industry. Based on the Dosys™ pumping technology, it guarantees ingredient integrity and a high level of hygiene. This technology ensures high accuracy in desired doses, handles fluids with high particle content, and guarantees the integrity of the ingredients. The systems are designed to reduce costly product losses and preserve ingredient properties.

High Level of Hygiene and Product Preservation

PCM solutions adapt to the specific constraints of food processing applications, cosmetics and pharmaceutical, particularly their requirements in terms of hygiene. All its equipment is designed to be cleaned in place and complies with local and international standards: food contact and hygienic design.

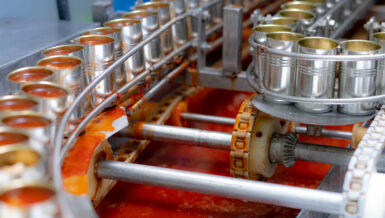

PCM has developed several adapted technologies, combining flexibility and productivity. These technologies can be used throughout the manufacturing process (transfer, preparation, packaging, etc.) and in a wide range of sectors: dairy products, beverages, bakery, etc.

A Wide Range of Standard or Customized Solutions

PCM solutions can be adapted to the specific constraints of food processing applications while ensuring versatility and respect for ingredients.

For example, the Hycare™ pump has been designed to meet the strictest food hygiene standards. It is specifically suited for microbiologically sensitive food applications thanks to its Duraflex flexible shaftline, preventing any retention areas.

The PCM Hyfeed pump, which won the EHEDG (European Hygienic Engineering & Design Group) hygienic design award at the CFIA trade show a few years ago, is ideal for transferring highly viscous, heterogeneous fluids with or without particles, pasty or even sticky, while ensuring bacteriological safety.

The PCM Easyfeed, on the other hand, is perfect for transferring highly viscous, heterogeneous fluids containing particles, as well as pasty or sticky substances. This pump is particularly well-suited for the meat and fruit & vegetable markets.

Another example of PCM’s expertise is the Dosymix™ inline mixer, which features twin helixes rotating in opposite directions. It enables gentle ingredient mixing and ensures an even distribution of the blended product.

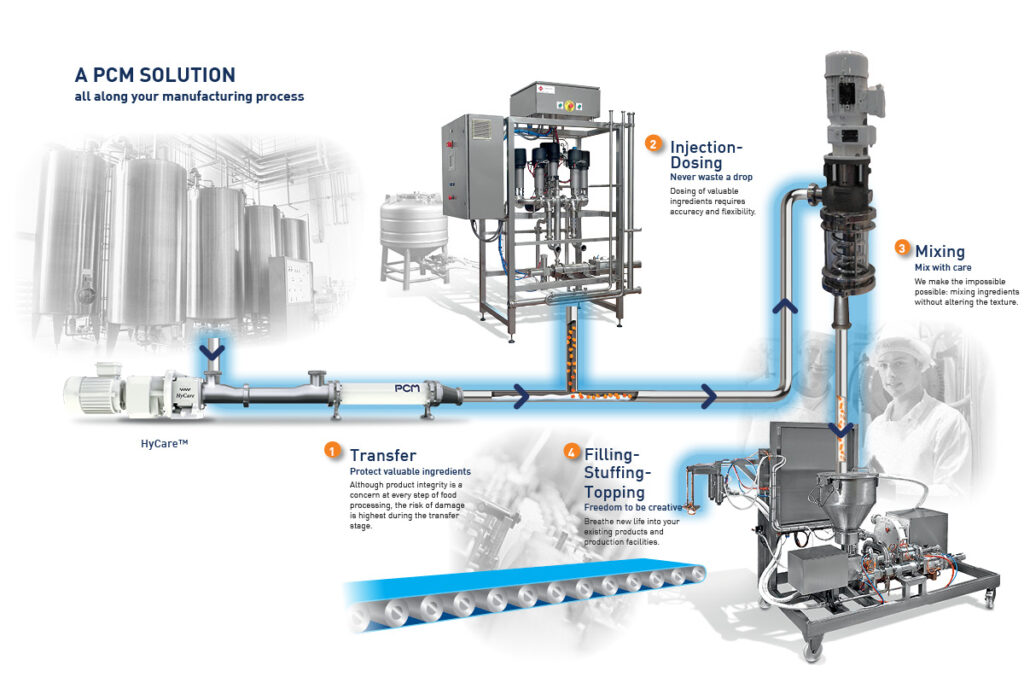

Integration into a Global System

The entire range of PCM products is compatible with a globally integrated system. For instance, an industrialized stirred yogurt production process could include:

- PCM Hycare™, for handling fluids while meeting the highest hygiene standards.

- PCM Dosymix™, a dynamic mixer that preserves the most valuable asset in your production line: the ingredients.

- PCM Dosyfruit™, for a semi-automatic process to produce fruit yogurts.

- PCM Dosyfill, a filling system ideal for handling viscous or fragile products, with or without markers, regardless of the container type.

This example highlights the fact that PCM solutions offer a complete range of products for the food, cosmetics, and pharmaceutical industries. Easy to use and maintain, they are highly versatile and ensure an optimal level of hygiene.