In contrast to wetted instrumentation, the non-invasive acoustic measurement distinguishes itself by its extremely large measuring dynamics and its high sensitivity even for very low flow velocities. In addition, as the clamp-on ultrasonic transducers are simply mounted onto the outside of the pipe, they do not suffer any wear and tear by the medium flowing inside and therefore do not cause any maintenance effort.

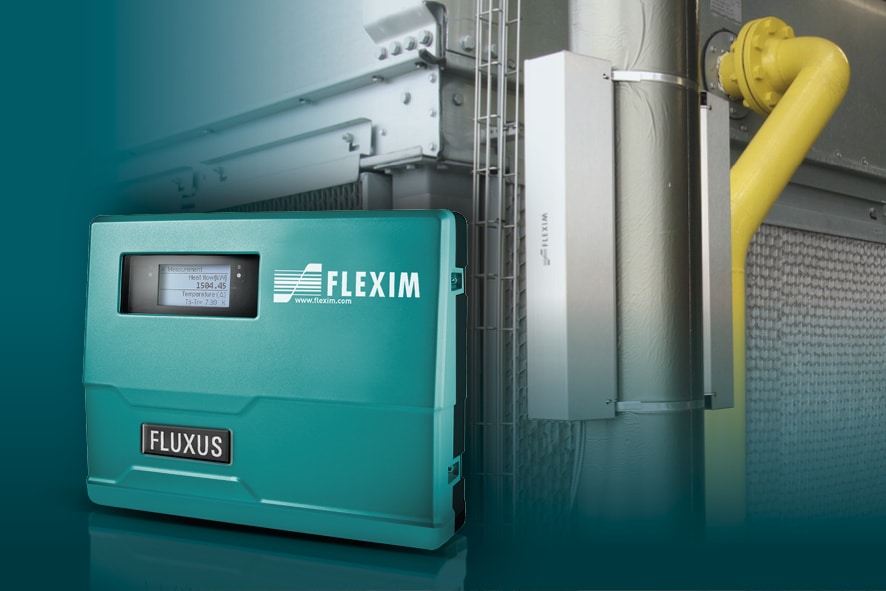

Both measuring systems are based upon FLEXIM‘s high-performing and field-proven stationary ultrasonic flowmeter FLUXUS 721. The fieldbus systems of the measuring transmitter allow for bidirectional communication, parameterisation and online diagnostics.

The heat flow meters FLUXUS F721 TE have been designed for non-invasive measurement of thermal energy flows of virtually any liquid heat transfer media, from deionised water, water-glycol-mixtures to heat transfer oils at temperatures up to 400 °C and above. Its ultrasonic transducers cover a pipe diameter range from DN 25 to DN 1000. Highly precise and paired (acc. to EN 1434 standard) temperature probes ensure the high accuracy of the energy measurement. In its dual-channel version, the FLUXUS F721 TE allows for simultaneous measurement on two different measuring points.

Ultrasonic flow measurement works independently of the flow direction with the same high accuracy. This characteristic is particularly beneficial when measuring compressed air. FLEXIM’s new FLUXUS G721 CA allows for precise balancing even in compex compressed air networks where flow directions can change depending on operation conditions. Non-invasive compressed air measurement on metal pipes requires a minimum pressure of 3 bar and covers pipe diameters from DN 15 to DN 250. For compressed air measurement on plastic pipes, no minimum pressure is required.