When COVID reached Europe, hospital estate managers of the UK’s National Health Service (NHS) quickly realized that their conventional way of measuring and securing oxygen supply was inadequate for the dramatically increased demand due to the pandemic. Therefore, they sought an appropriate measuring solution for real-time online monitoring of oxygen consumption. FLEXIM’s solution convinced through its double advantage: It delivers exact consumption data and is installed without any supply interuption. Since March 2020, FLEXIM installed dozens of oxygen flowmeters across many hospitals throughout the UK and Ireland.

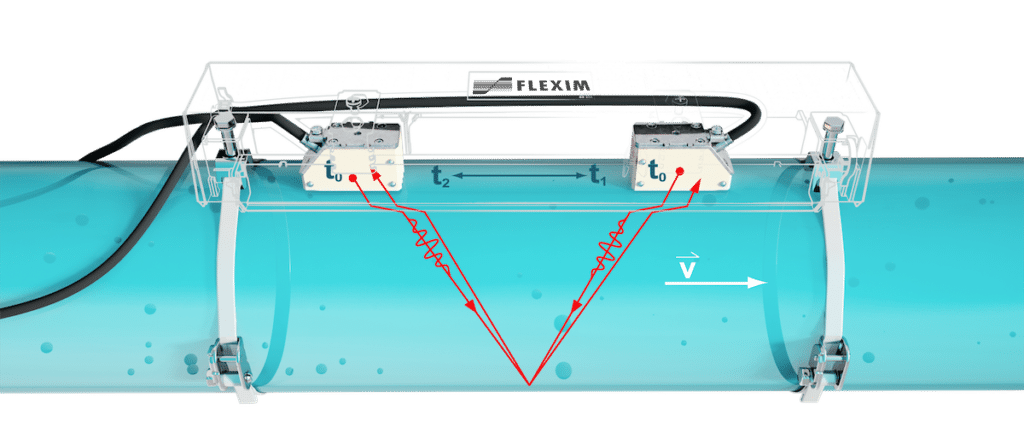

FLEXIM’s flowmeters work with ultrasonic transducers which are mounted on the outside of the pipe. The acoustic signal propagated in the direction of the flow runs faster than the return signal propagated against the flow. The transit time difference is proportional to the flow velocity of the oxygen or medical gas within the pipe. On the basis of the given pipe geometry and physical parameters, the transmitter than calculates the volumetric flow (standardised or mass flow is also possible if provided with temperature and pressure inputs for compensation).

Advanced digital signal processing and measurement algorithms of FLEXIM’s FLUXUS measuring transmitters ensure highly accurate and repeatable flow measurement data, instantly capturing changes in the flow regime. Data is either transmitted via simple 4-20 mA output, or via a communications bus, such as BACnet or Modbus, to the local building management system, where there is usually some form of interface presenting a real-time dashboard of oxygen use for the use of estates or clinical staff. Some hospitals even have remote tablet dashboard displays and emailed or texted alarms sent to relevant personnel, including the MGPS Authorised Person. The greatest advantage in the application of the FLUXUS G721CA clamp-on flow meter, however, is the ability to install without any shutdown to the critical delivery of oxygen. All commissioning takes place on live, working oxygen delivery pipes, with zero interruption to daily hospital care activities.

With his portable FLUXUS G601 CA Energy, FLEXIM’s service engineer was able to convincigly demonstrate on site the suitability of the non-invasive ultrasonic technology for the measuring task.

“We at FLEXIM are proud to be playing our small part in the fight back against COVID-19 and supporting our UK health service during this period of unparalleled demand”, says Andy Hammond, Managing Director at FLEXIM Instruments UK. Since spring 2020, he and the UK FLEXIM supported the NHS to manage the secure supply of oxygen to Corona patients. “On behalf of the NHS, we particularly want to say thank you to our Berlin colleagues in order handling, production and shipping who have stepped up efforts to produce the urgently required flowmeters, even with reduced personnel shift patterns due to COVID-19 safeguarding in the workplace. Thank you, TEAM FLEXIM!”