To reduce costs, manual errors, and labor, the tank farm decided to automate tank level management by implementing a wireless sensor control system.

While different telemetry systems are on the market, the tank farm wanted a highly reliable sensor control system that would not drop signals when transmitting information from sensors located on the tanks. In addition, a reliable power source was needed to support the 24/7 terminal operations.

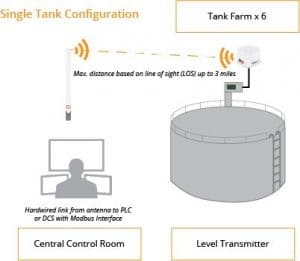

A Signal Fire Remote Sensing System consisting of five battery-powered Sentinel HART nodes and a stick-mounted Gateway offered a cost-effective solution in creating a strong sensor network as part of remote tank leveling application. Battery-powered Sentinel HART nodes power levels sensors installed on top of tanks without the need for line power. The Sentinel HART offers the versatility to power and integrate with most level sensor types. Sensor data is transmitted to a Gateway integrated into a control room PLC or DCS via a Modbus interface. Installation is easy as nodes automatically configure within a SignalFire mesh network.

To reserve battery power, Sentinel nodes are configured to a fixed transmission cycle and sleep mode. To reinforce and create a stronger network, the solar-powered Sentinels are centrally located in the tank layout to provide the network with a level of redundancy. If a battery-powered system ever got a low power and could not reach the control room, the solar-powered system served as a repeater.