Condition-based maintenance concepts are clearly superior to those based on regular maintenance intervals. They do not only save costs, but also reduce the risk of unplanned downtime. A special challenge are valves and flaps installed in closed systems. The French company Dynavia relies on the smart MVQ101 valve sensor from ifm for their seed treatment installations.

Since antiquity, seeds have been treated in agriculture in order to protect them from diseases, insects and birds. Today, highly-specialised fungicidal and insecticidal agents are used that have to be applied to the seeds as carefully as possible.

Modern plant technology

Founded six years ago, the start-up company Dynavia concentrates on the development of modern installations for seed treatment that are also suited for the combined processes of the next generation, e.g. with biological stimulants. The young company opts for innovative solutions to ensure particularly careful treatment of the seeds. For example, the material in the mixers is only moved with great care in order to minimise mechanical impact. The treating agent is applied via several nozzles which are strategically positioned in the container. This ensures a very even distribution.

The modern installations, which are suited for processing large amounts of seeds, comply with the standards of the food industry. For example, the containers and pipes are made from stainless steel and all parts of the installation can be cleaned without removal. Thanks to this cleaning in place (CIP), the operators do not come into contact with the treating agents. The CIP process is fully automatic, no intervention from the operator is required. As a rule, the different parts of the installation are cleaned with hot water at different flow rates and then rinsed again.The cleaning water is collected, filtered and recycled.This makes the installations very environmentally friendly.

Sensor technology based on IO-Link

Dynavia also rely on state-of-the-art equipment when it comes to control technology. For example, all sensors used in the installations feature IO-Link interfaces. “We fully commit ourselves to Industry 4.0, this is why we exclusively use IO-Link sensors,” explains Dynavia’s Digital Project Manager. The company relies on ifm electronic as their supplier of sensor technology and purchases pressure, temperature and level sensors as well as valve sensors for pneumatic quarter-turn actuators.

“The connection of the sensors via IO-Link helps the operator to keep an eye on the entire installation, which may be quite extensive,” says the expert from Dynavia. Another advantage of this technology is that no complex configuration is required if a sensor is replaced – the IO-Link master simply transmits the settings of the old sensor to the new one. This saves time and thereby reduces the costs of service calls.

Position indication with special functions

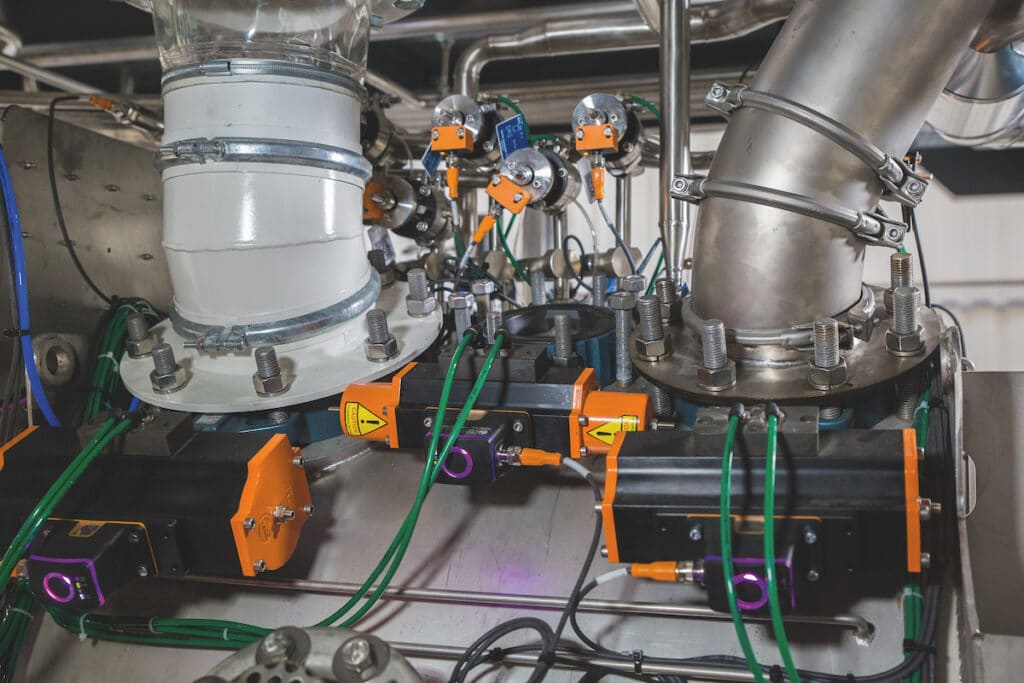

Dynavia also use the new MVQ101 type valve sensor for pneumatic quarter-turn actuators in their installations.The MVQ101, which is also connected to the control system via IO-Link, provides much more information than the usual binary position signal that only indicates the “open” or “closed” state. The MVQ101, on the other hand, measures the exact angular position of the quarter-turn actuator. This is real added value in the installations for seed treatment. Deposits on the gaskets of the quarter-turn actuators may prevent their closing correctly. The new valve sensor precisely detects this, so that the higher-level controller can react accordingly. It will start an automatic cleaning process which will remove the deposits, thereby solving the problem without delay.

The smart MVQ101 valve sensor can be adapted according to the application. This can be done via the parameter setting software or the inductive teach button on the device. The button can be used, for example, to teach the end positions of the quarter-turn actuator and set the switching area. A third switch point can be selected, for example for three-way valves or for switching off the pump to avoid pressure peaks. The position of the quarter-turn actuator is indicated by a 360° LED ring, which is visible from all sides, and a mechanical position indicator which visualises the position even if the unit is not powered. The clearly visible LED ring around the sensor is yellow if the valve is open and blue if it is closed. Incidents are indicated in red.

The seal monitoring described above, which detects soiling, is not the sensor’s only diagnostic function. It also monitors how long it takes for the actuator to open or close, for example. If the time required changes considerably, this may indicate imminent malfunction. Besides, an integrated counter detects how often the valve opens and closes. The diagnostic functions of the MVQ101 help to optimise condition-based maintenance. When compared to defined maintenance intervals, the overall availability of the system is increased while maintenance costs are reduced.

Implementation of a new function

In the context of the cooperation between Dynavia and ifm, a new function was developed for the valve sensor.The installations for seed treatment are often very large and spread over several levels. If a valve is to be replaced during a service call, the employees have to locate the valve concerned in the system as quickly as possible. “Based on our proposition, ifm have implemented a new function in the valve sensor,” says the Digital Project Manager. “The LED ring flashes purple if this function is activated via the controller. This helps the employee to immediately locate the valve in question and get to work.” This is extremely helpful, particularly if there is a great number of valves installed in the system. In the past, the wrong valve was replaced occasionally. Thanks to the newly implemented function, such mishaps are a thing of the past.