More than 25 years ago Steinle Industriepumpen GmbH, a Partner of Tapflo in the German market, developed its own piston-diaphragm system used for the feeding of filter presses with a capacity of up to 18 m3/h. The design has gone through 5 versions with constant quality improvement since 1989.

A long professional relationship between Tapflo and Steinle resulted in the agreement and transfer of know-how and production from Steinle Industriepumpen GmbH to Tapflo.

“Thanks to the production capabilities and high-end machine park of the Swedish manufacturer, the adaptation of the production lines to support a new product has been very smooth

Mikołaj Laguna-Horodniczy head of Marketing at Tapflo Group.

The Steinle Pump satisfies the need for robust and durable systems in demanding applications where liquid transferred to the filter press requires high-efficiency pumps.

“In this kind of application in addition to the extremely high demands placed on performance, the pump is often severely stressed by the liquids as most slurries are abrasive and are often also chemically aggressive” – says Jakub Zduńczyk Product Engineer at Tapflo Group.

The Steinle Pump transfers large quantities of liquid into the empty press as well as small quantities at high pressure when the filter press is filled.

The most important reason for choosing a Steinle pump, besides its reliability, is the high transmission value of the inlet air pressure (up to 1:3.3) to the outlet pump pressure. High pressure in the filter press means a better filter result, lower costs for the removal of the filter cake and a shorter pressing process, together with optimal utilization of the equipment.

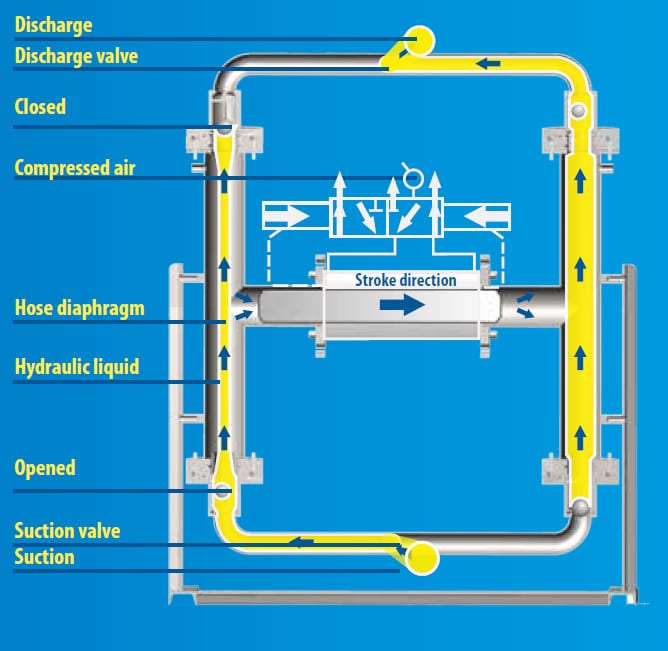

Working principle

Compressed air moves the pneumatic piston which is attached to the hydraulic piston. The hydraulic piston moves the hydraulic liquid which acts on the diaphragm hose which also restores its original shape. While the hose is compressed, the slurry inside is displaced and flows out. Ball valves on the top and bottom of the hose ensure that the flow is in one direction only.