A large percentage of the water supply is then collected and managed to provide clean drinking water and other services back to the community. The largest water system controller in Melbourne, Australia came to Hawk Measurement (HAWK) to help provide a level measurement solution that would assist with the water system’s emergency shut off valves.

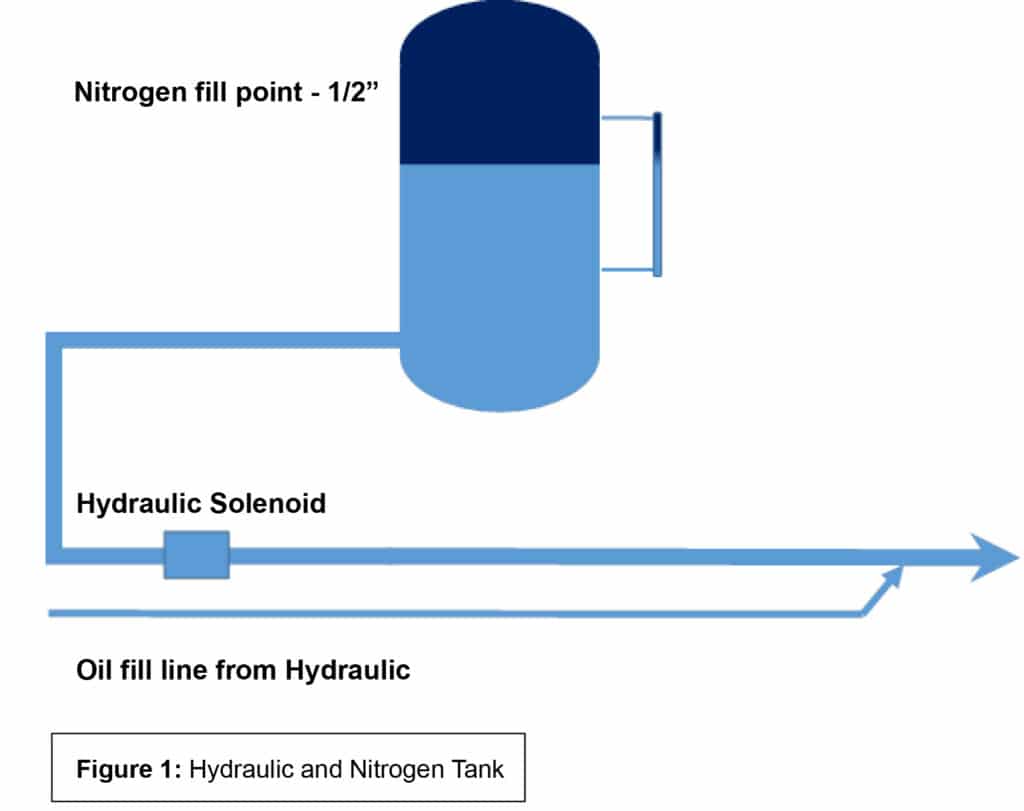

The application consisted of a tank filled with Hydraulic Oil (bottom of tank) and Nitrogen (top of tank). The Nitrogen is inserted at the top of the tank to push the oil in the line and keep the hydraulic actuator functioning properly. The system acts as an accumulator with capacity to shut off valves in the event of an emergency shutdown. It also acts as a hydraulic dampener. Pressure switches are installed on the system, which recognize a drop in pressure (set at 560psi falling), when a hydraulic actuator in the field operates. As the oil level in the accumulator drops, so does the pressure. Nitrogen in the tank is initially setup with typical operational level of hydraulic oil systems. As the system is closed, there is no need to add more nitrogen afterwards.

Sensed by the pressure switch, the hydraulic oil pumps are activated and pump more oil into the system. The oil is not brought directly into the tank, but downstream of the accumulator as shown in Figure 1. Typical oil movement is approximately 100 – 150mm level change. Tripping the pumps out at approximately 605psi, the oil that is put back into the accumulator returns to the previous level.

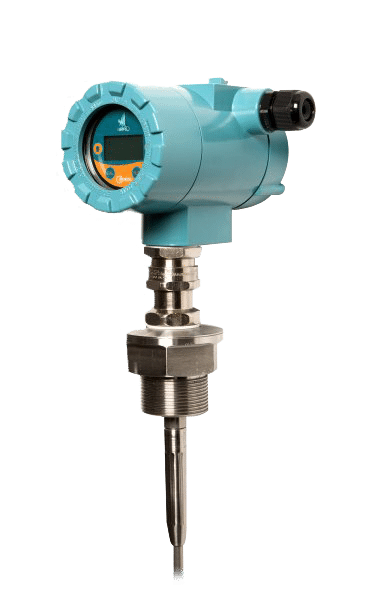

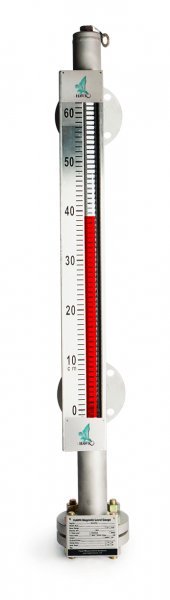

HAWK’s Magnetic Level Gauge (MLG) with Chamber along with the Centurion Guided Radar (CGR) Level Transmitter was the level measurement solution to this difficult application. The CGR’s were installed to measure the level of hydraulic oil in the MLG Chambers, and they also supplied the analog output. HAWK’s MLG was selected because they provide real-time measurement for level and interface. The CGR was selected because it’s ideal for level interface measurement of liquids, sludge, powders and granules. The CGR technology is not affected by pressure, temperature, viscosity, vacuum, foam, changes in the dielectric constant or coating of the probe. The water system controller was extremely satisfied with the outcome of HAWK’s solution and the technologies and services provided.

The Centurion Guided Radar (CGR) Level Transmitter is ideal for the measurement of liquids, sludge, powders and granules to a range of 38m (124ft) for level and interface. This technology is not affected by pressure, temperature, viscosity, vacuum, foam, dust, changes in dielectric constant or coating of the probe.

The HAWK Magnetic Level Gauge (MLG) is widely applied in the monitoring and process control of liquid level and interface for many industries; such as petroleum, chemical, power, paper, metallurgy, water treatment etc.