After the introduction of the mini version TSM, users were enthusiastic about the simple configuration, the problem-free commissioning, and the new functions based on the flex-hybrid technology with digital and analogue data transmission.

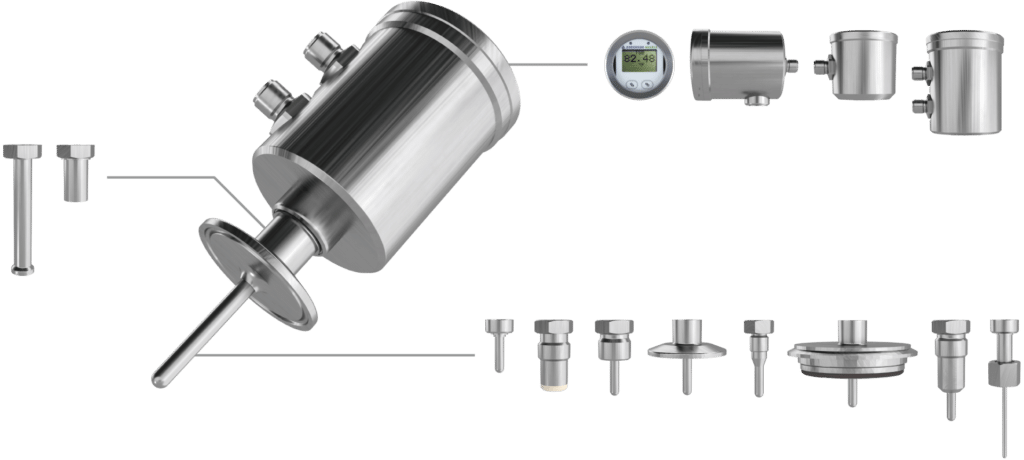

Now the compact version TSB follows with even more variants, application possibilities and options, such as:

- Dual Pt100: The dual RTD sensor enables dual, parallel measurement and thus self-monitoring of the sensor performance. This is just one option among many combinations of single and dual RTD, type Pt100 or Pt1000, and accuracy class A, AA, or AAA.

- LCD display: The sensor head can be equipped with an easy-to-read LCD display for optimised on-site control and can also be oriented horizontally or vertically.

- Choice of 0, 1 or 2 transmitters: The right solution for every PLC connection.

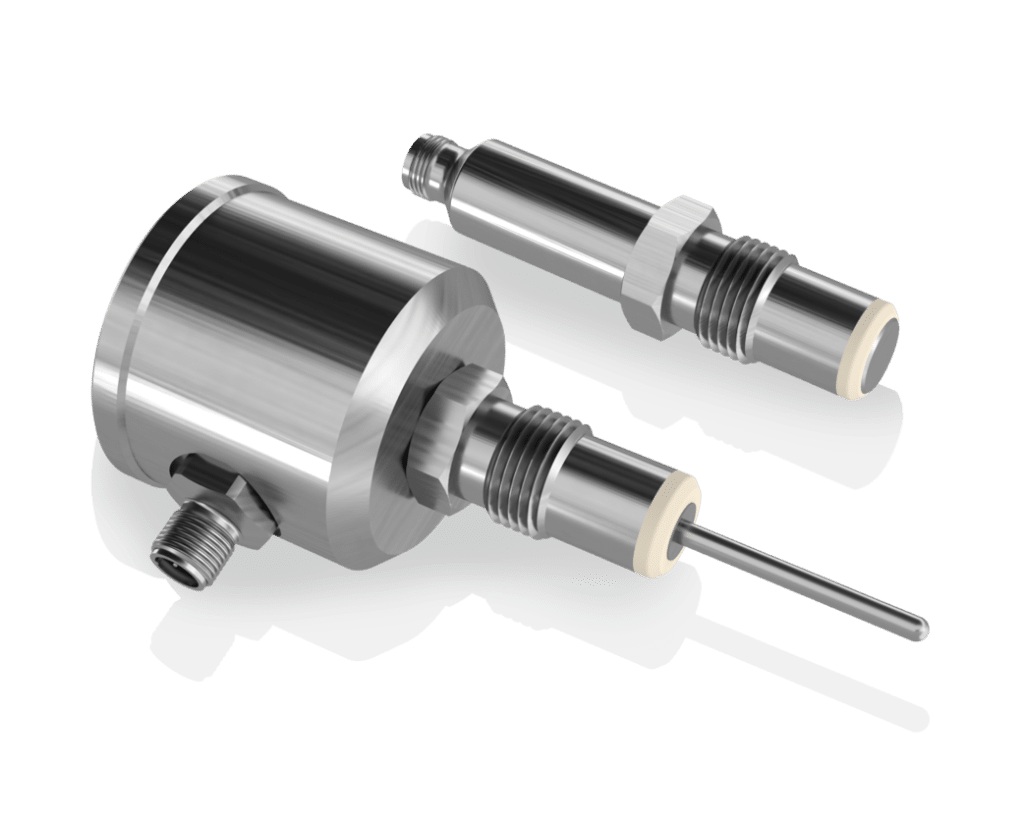

- CLEANadapt with PEEK sealing edge: This new hygienic screw process connection is based on the excellent experience of the CLEANadapt metal-to-metal solutions. The new sealing zone made of highly resistant PEEK has already been 3-A approved.

The Flex Hybrid technology with IO-Link and 4…20 mA combines the best of both worlds: Data can be transmitted from the sensor in digital or analogue mode.

- Flexible communication with plug and play saves time and money during installation and commissioning.

- Simple individual programming with IO-Link master, e.g. for changing the measuring range or for two-point adjustment using zero point and slope. The USB – IO-Link Master IOM-01 is available as an accessory.

- Sensor replacement is easier than ever before thanks to the “Smart Replace Design” with automatic sensor identification, configuration, and parameterisation via IO-Link.

With further improved product performance, TSB is the new benchmark for temperature with extended process temperature range from -200 to 400 °C, improved measuring accuracy of < ±0.1 K, higher ambient temperature resistance and a one-piece design completely in stainless steel which provides lasting stability and application safety.

The freely configurable modular concept allows you to assemble your individual desired sensor in just a few steps. At the same time, the TS series is fully backwards compatible, both mechanically and electrically, and can thus replace any existing TFP sensor without modifications. TS thus offers a suitable solution for every application. For new equipment, the modular design together with the Flex-Hybrid technology means maximum flexibility and future-proof set-up for every application. For retrofitting, TS can replace any TFP Mini sensor in existing systems – with all the additional advantages. And finally, for the replacement of third-party devices, a suitable model is always possible due to the large selection of process adaptations and maximum flexibility in configuration.

Thanks to the wide range of variants in each of the 5 configuration levels, almost all requirements in food or pharmaceutical applications can be realised:

- The flush version, for example, is ideal for installation in containers with agitators or other mechanical devices and enables hygienic pig cleaning in pipes.

- A thermowell allows the sensor to be removed without opening the process. The suitable process adaptation can be welded in, screwed in, or installed as a clamp connection by means of an adapter. During operation and without the risk of contamination, the TS can be removed or replaced at any time for testing or adjustment.

- Sensor tips in various diameters and lengths from 0 to 2000 mm allow very specific adaptation to the respective installation conditions and very short response times required for process control.

- The huge selection of process adapters for screw and clamp connections allows the TS to be installed on almost any existing process fitting.

- In the further configuration stages, a choice can be made from different spacers for adaptation to ambient temperatures, a sensor head with or without transmitter and a selection of electrical connections with protection class IP 69K.

The Mini Version TSM is already available. The Compact version TSB will be launched in August, an “At a glance” document with the most important product highlight can already now be downloaded as PDF file.