You know instantly what’s wrong, the impeller is clogged up again stopping the pump from processing any water. For mobile pumps there is an additional issue, through the changing levels of sewage water the pump has to process a lot of air. Anyone who has ever seen this knows the result, the vibrations in the pump are so strong that you need to take a few steps back.

Sewage water problems

Handling sewage water has always been a challenge and its nature is constantly changing. There are also great differences between the sewage systems across countries and their respective levels of pollution.

It is often the large solids and long-fibrous materials that place real demands on sewage pumps. In addition, we should not underestimate the irregular volume and flow of air within the system, making it difficult to make the right pump choice.

You are going to see all kinds of things, and that smell if you have to fix a blockage! Probably this is where the phrase “it’s a dirty job but someone’s got to do it” started out.

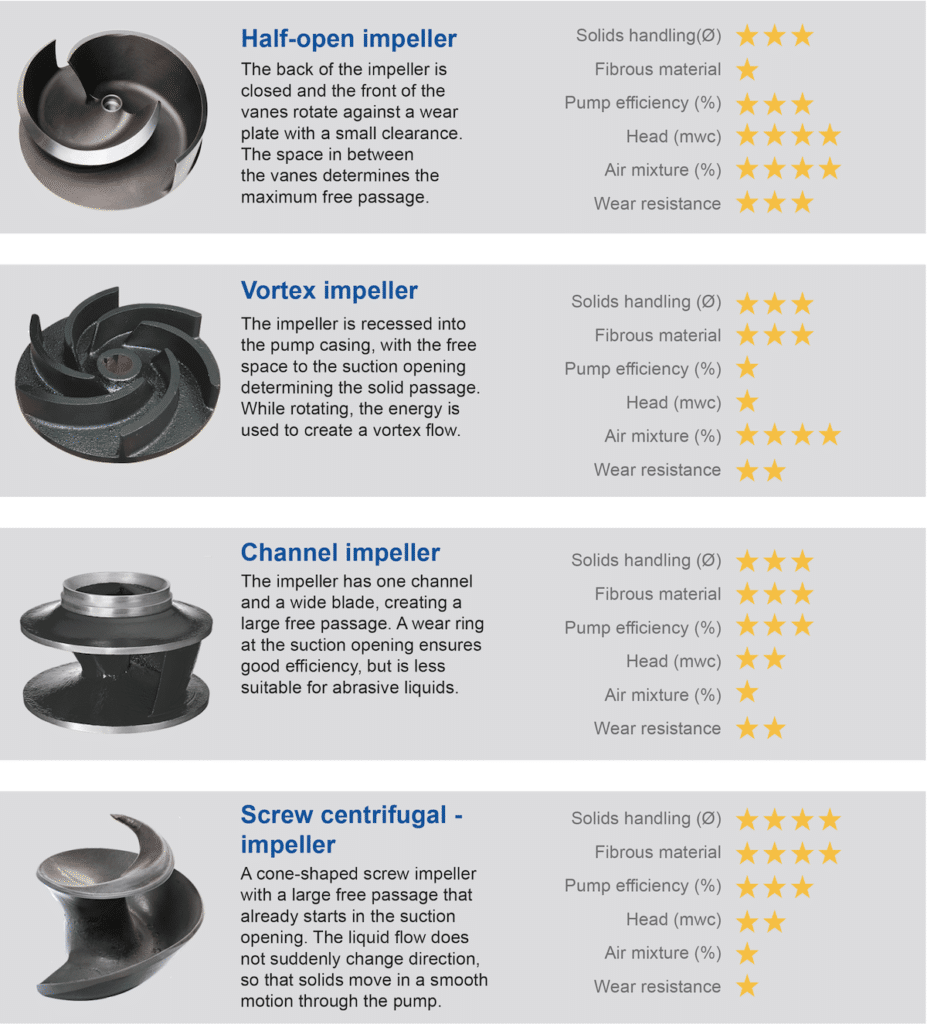

If the correct pump size has been determined based on the sewer capacity and the required pump pressure, then the key for a trouble-free pump installation ultimately lies in the choice of the impeller. This brings us into the world of pump designers where the technology goes beyond just the addition of a large solids handling. In the design department, the engineers always have a long list of requirements. At the same time, they must not compromise on pump efficiency, hydraulic performance, suction lift, solids handling, mechanical noise level and most certainly not on product quality.

Prevention is better than cure

How can you prevent blockages or avoid high repair costs due to vibrations on sewage pumps? In order to answer these questions, we will first look at the unique properties of the different sewage pump impellers.

The unique features of different sewage pump

In order to avoid getting bogged down in boring design terminology, we focus on the heart of the matter, the pump impeller. In order for you to reach a good conclusion we have listed the features of the impeller types which are suitable for pumping sewage water.

Is there such a thing as the perfect impeller for pumping sewage?

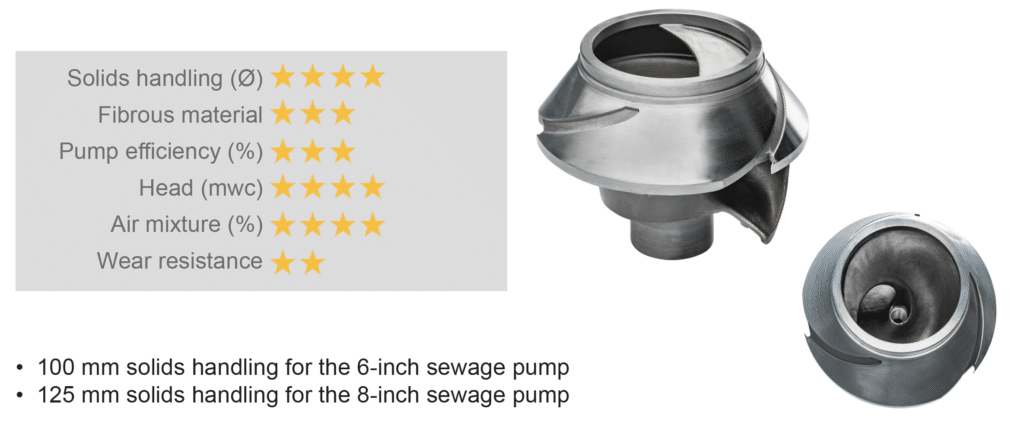

Sewage water specialists know that the screw centrifugal impeller with two 5 star ratings is excellent at pumping large solids and long-fibrous materials. But there are also a few drawbacks to this impeller, which are especially applicable to mobile sewage pump installations.

Vibrations at higher speeds

The design of the impeller has the shape of a corkscrew and is therefore difficult to balance. This is why the pump cannot run at higher speeds and becomes very restless when there is a lot of air in the volume flow.

Another disadvantage is the sensitivity to wear. If sand is present in the liquid, the clearence between the impeller and cone will quickly increase, causing the efficiency to drop.

Wouldn’t it be great to combine all the good features of the different sewage pump impellers into one design?

The half-open impeller is already close to perfection. Some manufacturers work with cutting blades or cutting grooves in the wear plate that chop fibrous materials into smaller pieces. The chance of blockages is therefore reduced, however, it never works completely flawlessly.

The solution is the KS screw channel impeller

Through a smart redesign we can turn the drawbacks of the screw centrifugal impeller into positive properties. The solution is now available and the results are amazing. The corkscrew design remains, but it gets its own “flywheel”, which creates much more stability during pumping.

“The screw channel impeller has significantly less clogging than the half-open impeller”

This allows the speed to be increased to 2300 rpm and the pump continues to run vibration free. The big advantage of a higher pump speed is the higher pressure that the pump delivers (more than 4 bar).

Air in the volume flow is no longer a problem. Further, if sand is present you will now have much less wearing, because the liquid is no longer guided along the cone.

Centrifugal pumps deliver more pressure with a higher pump speed

You need pressure to bridge the height difference and pipe friction loss while pumping a certain amount of liquid. This is especially true for mobile sewage pumps, the more pressure the pump can deliver, the more flexible you are to take on bypass projects. The calculation example below clearly shows that increased pump pressure is not an unnecessary luxury.

Practical example of a temporary sewage pump installation

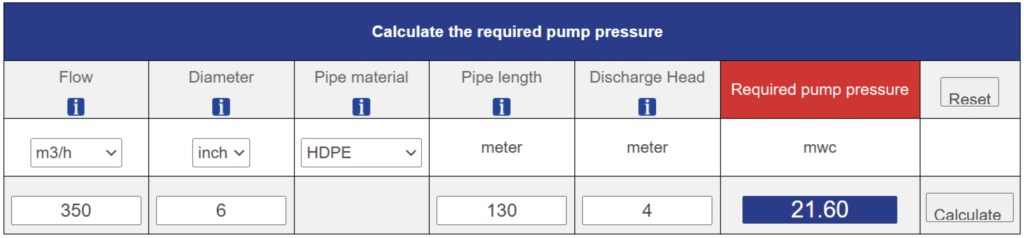

In a random city district, the existing sewerage system must be replaced. According to the specifications, the waste water flow must be maintained by a temporary pump installation with a minimum capacity of 350 m3/hour. The drain in which the discharge takes place is just 130 meters away on the same side of the street, so for the sake of convenience we do not count the resistance losses of accessories.

The sewer has a maximum depth of 3 meters and the height difference on the discharge side is just 1 meter. Given the required capacity, a 6-inch sewage pump including connected piping seems obvious. The system calculation will then look like this:

- Maxium capacity 350 m3/hour

- Total 130 meter 6-inch pipe work

- The height difference is 4 meters

You will find various pipe resistance calculators on the internet from which the required pump pressure can be easily and quickly calculated. Despite the compactness of the temporary sewage installation, the pump in this example already has to deliver almost 22 mwc pressure to guarantee the required waste water flow.

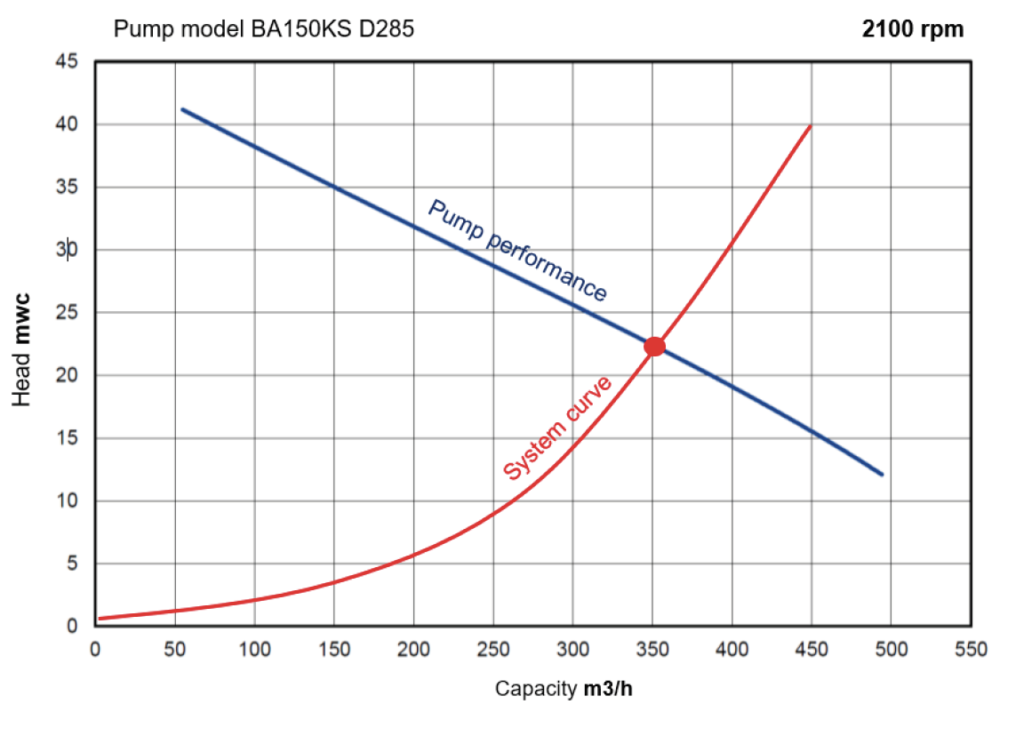

As a solution to the practical example, we can take the BA150KS D285 with a diesel engine that runs at 2100 rpm (still below its maximum speed). We can visualize this well in a diagram showing the pump performance and the system curve. We call the intersection point of these two lines the operating point.

”The screw channel impeller is affected much less by vibrations from air bubbles and/or higher speeds”

In practice, the KS screw channel impeller has a clear advantage at high speeds. Delivering a greater pump pressure without fear of vibrations should air bubbles occasionally come along.

The KS screw channel impeller

This specially developed closed KS screw impeller is a real waste warrior. The pump also runs vibration-free at high speeds. Air or gas bubbles in the volume flow are no longer a problem. Further, if sand is present, you will have much less wear, because the liquid is no longer guided along the cone.

Conclusion: The KS screw channel impeller is the best choice for sewage pump work.

“The really great feature of the KS screw channel impeller is the head. Compared to the existing mobile sewer pumps, this pump delivers much more pressure”