The situation

The Polish city of Tomaszów Mazowiecki (pop. 80,000) had an ageing wastewater plant that was built in the 1970s. It needed too much maintenance, consumed too much energy and by the 2000s, it had trouble continuously keeping its effluent numbers low enough.

“It was technologically obsolete,” says to Waldemar Debowski, the municipal plant’s manager since 1993. “The aerators consumed a lot of energy and produced little oxygen. They accounted for 80% of our energy consumption. It wasn’t an ideal solution.” The city received EU funding to rebuild its plant. In 2013, it awarded a tender to the Budimex-Cadagua consortium. The contracting group began designing a new chemical and biological treatment plant. The requirement for shallow (3.9 metre-deep) tanks provided a challenge in designing and building an energy-efficient aeration and mixing system.

The solution

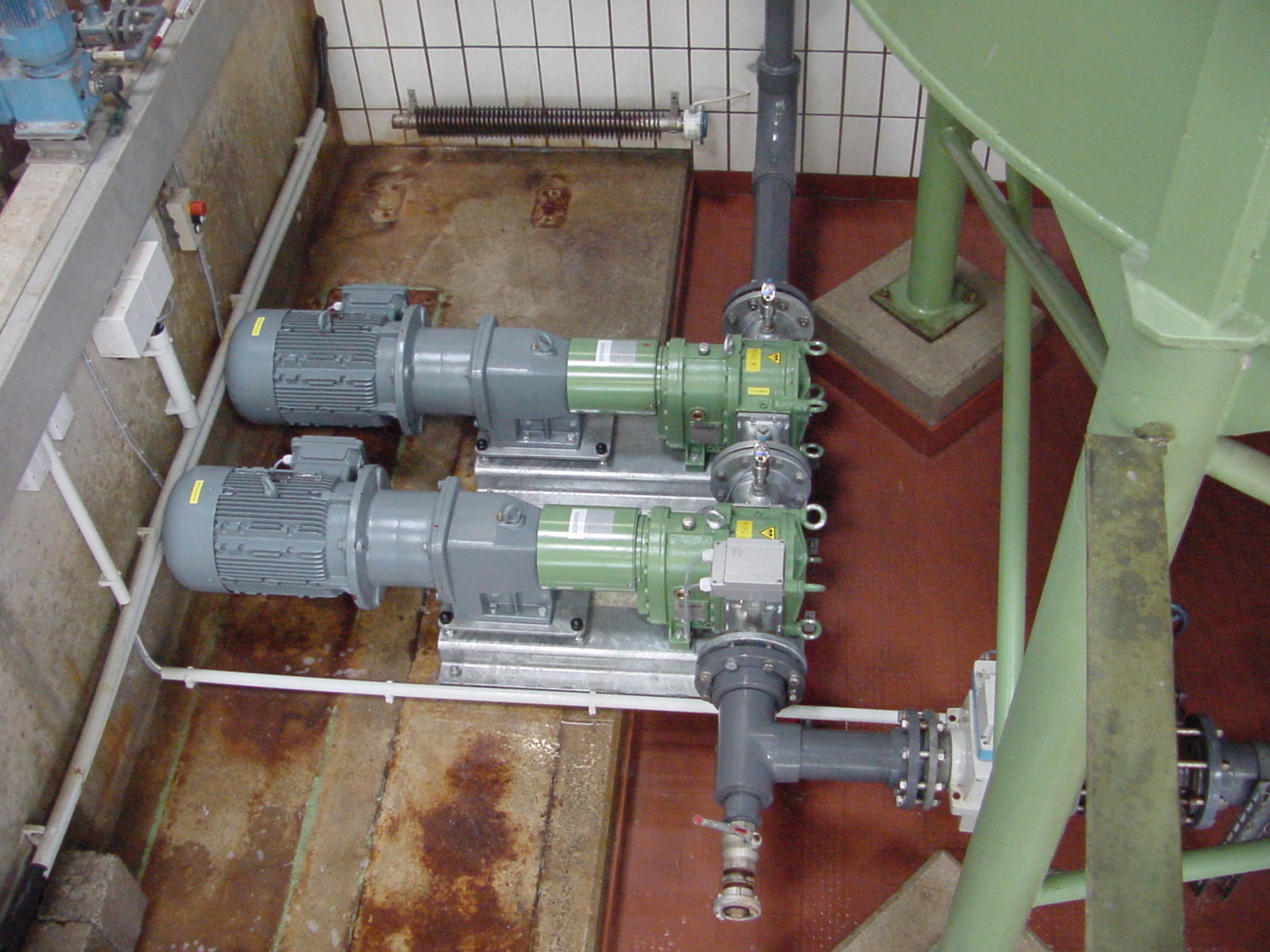

Early in the process, Cadagua awarded Grundfos supply of pumps, dosing equipment and boosters, plus all the equipment for the bioreactors, including aeration grids, mixers and blowers. Grundfos also headed up the bioreactors’ design, sub-supply and assembly.

“Grundfos has been with us from the very beginning,” says Adam Bierut, Contract Manager, Cadagua. “Grundfos was actively involved in designing the plant. The bioreactors are the most important part of the plant. It’s where the nitrogen and phosphorus are removed. They were designed by Grundfos.”

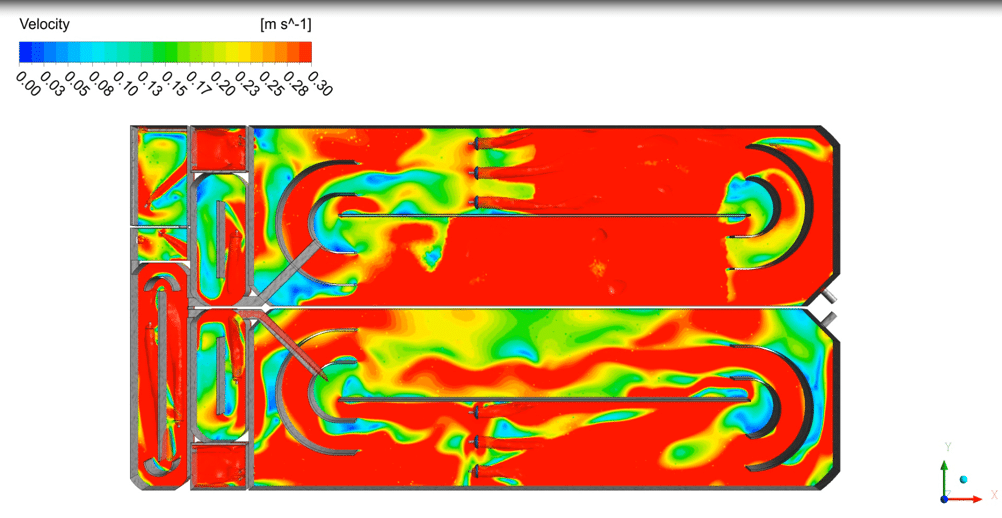

Grundfos used computational fluid dynamics (CFD) modelling and simulations to develop the ideal flow paths for the bioreactor. CFD helps to evaluate and optimize the bulk flow generation, patterns and velocities as well as mixing performance.

The outcome

“This is one of the few biological treatment plants in Poland that can lower the nitrogen level to 4-5 mg/l at the outflow and the phosphorus level to 0.4 mg/l,” says Adam Bierut. “So all the equipment and the design are well suited to the task.”

Plant manager Waldemar Debowski says the modernisation of blowers and aeration system alone has resulted in a much lower energy consumption as well as the better parameters on treated water.

“I can say that Grundfos is our most important supplier” Debowski says.

“After we implemented the solutions suggested by Grundfos, our energy consumption dropped by 50%. But the most important result for me is the highly efficient aeration. Even on hot days maintaining the carrousel’s parameters is easy. It’s the most important thing for me as a technician.”

The treated outflow from the municipal plant goes into the Pilica River – one of the longest tributaries of the Vistula River in Poland. It flows some 800 metres away from the plant through a nature reserve.

“The parameters of our treated effluent are better than the parameters of the river water,” he says. “So in short, we refine the water in the Pilica.”

Mixers:

AMD, AMG, AFG, SRP

Pumps:

S2, SL1, SE1, Unilift AP

Boosters:

NBG pumps with control cabinets

Complete coagulant dosing station with DDA and control cabinet

Diffusers:

Jager Umwelt Technic

Blowers:

Pillaer