INDUSTRY

Pharmaceutical – Animal Vaccine Manufacturing

CUSTOMER

A world-leading animal health company, manufacturing a wide range of products from vaccines to wellness products.

BACKGROUND

The customer’s US facility, which has been operational for almost 30 years, produces animal vaccines for various animal species ranging from dogs and cats to chickens, coyotes, and raccoons. Therefore, a complex variety of aggressive chemicals, steam, and mineral oils are used throughout the process in multiple applications.

CHALLENGES FACED

Over time, the plant had gradually introduced an increasing variety of elastomeric gasket materials to ensure compatibility and compliance across each process. As well as the complexity of specifying, validating, stocking and maintaining multiple gasket materials, the customer encountered many problems which continued to challenge process reliability and integrity:

- Steam exposure – gaskets would creep, causing the seal to loosen and leak over time.

- Mineral oil exposure – oil would attack rubber seals and cause premature failure.

- Chemical exposure – the plant had to fine-tune the elastomer selection for each process area.

OPERATING CONDITIONS

1. Size: ½” – 2” (ASME BPE)

2. Temperature: -120°F (-184°C) to +350°F (+176°C)

3. Application: Process Lines, Hygienic Couplings

4. Media: Clean Steam, Mineral Oil, Chemicals

5. Pressure: up to 100psi (6.9bar)

SOLUTION AND BENEFITS

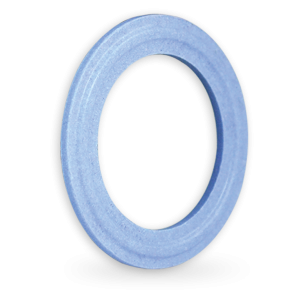

Following successful trials across several application areas, Garlock’s GYLON BIO-PRO® sanitary gaskets were adopted due to their superior performance, reliability, and extended service life. The plant runs on steam 24 hours per day, 7 days per week, so any leak/failure of a gasket is critical. The Garlock solution allows for longer service life of these systems so the plant can maintain running conditions as needed. Additionally, the unique GYLON® material does not creep in the steam lines, which ensures that maintenance teams do not have to regularly re-torque each hygienic coupling after thermal cycling.

By switching to GYLON BIO-PRO®, the customer has also enjoyed the benefit of using a single gasket material for all process media and clean utilities. This means that all elastomer and PTFE gaskets are consolidated, reducing inventory and avoiding potential gasket selection errors. By switching to a Garlock solution, the customer is now enjoying improved efficiency and peace of mind.