The instruments are directly mounted into the main pipes, at the outlet of the compressor. In the first step the compressed air consumption in the main supply line is recorded ideally by means of an intelligent chart recorder, simultaneous a measurement of the power consumption of the compressor should be carried out.

By measuring power consumption and the compressed air output simultaneously, it is possible to calculate the specific power of the compressor in → kWh/m3. The specific power gives us an indicator of how much energy is required to produce one cubic meter of compressed air.

The specific power is calculated using the ratio of the required energy consumption in kWh in relation to the compressed air output in m3, during the same period. Since the energy costs are the biggest part of the cost distribution of a compressed air system a recording of the described values is strongly recommended to take actions if the compressed air production gets inefficient over the time.

The main challenge while measuring the direct output, or the FAD of your compressed air system are the rough conditions the flow meter should be able to work, as well as the high velocities that could occur and have to be covered.

The directly ejected compressed air is mostly hotter as with a usual compressed air flow measurement, also the humidity grade is nearly saturated therefore the appearance of condensate is possible. This kind of conditions are not suitable for every kind of measuring principle.

The VD500 flow meter allows a measurement up to 600 m/s, beside that the device is suitable for hot and wet conditions. A measurement directly at the compressor outlet up to 180°C is possible. The most suitable, and reliable flow meter you will find for your FAD measurement.

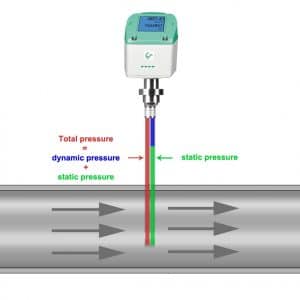

The integrated, precise differential pressure sensor measures the differential pressure/ dynamic pressure at the sensor tip. The pres- sure depends on the respective gas velocity. The flow is therefore easy to determine by means of the pipe diameter.

The additional measurement of temperature and absolute pressure and calculation of the relevant density means that measuring can be carried out for various gases, a wide variety of temperatures and pressures.