3 FLEXIM flow meters are installed at the entrance to the treatment plant; 2 on the pumping lines and 1 on the main pipe.

Non-intrusive ultrasound technology is particularly suitable for this type of measurement.

The multiplication of the number of sound paths made possible by the power of the FLEXIM sensors makes it possible to improve the measurement accuracy in spite of reduced straight lengths.

In addition, the non-stop commissioning of the raw water supply process from the WWTP and without piping work makes FLUXUS flowmeters installation particularly economical.

Finally, since the transducers are not in contact with the fluid, the measurement remains reliable over time without any maintenance.

Advantages

- No maintenance unlike electromagnetic flowmeters

- No interruption of the process of arrival of the raw water during the installation

- No modification of piping

- Capability to measure particle loaded waters

- Gain in CAPEX & OPEX

Measuring Points and Instrumentation

Medium: Loaded waters

Pipelines: Carbon steel, DN600, DN300

Measuring devices:

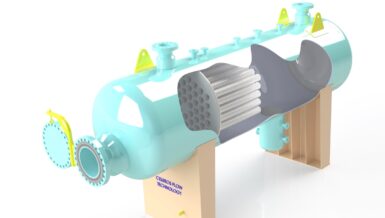

3 stationary clamp-on ultrasonic FLUXUS® F704 flowmeters

3 pairs of CDM transducers, mounted with steel tension belts designed for large pipe diameters

Flow measuring point with clamp-on ultrasonic transducers mounted on a DN600 pipe

Stationary FLUXUS F704 ultrasonic systems are used as measuring transmitters.

Customer

Saur, WWTP of Saint Fons, Rhône, France

A leader in the delegated management of environmental services, the Saur Group supports local authorities and industrialists in their water-related development projects (Saur), public cleaning (Coved), engineering (Stereau), construction works (Cise TP) and recreation (Blue Green and Flower Campings). Internationally, Saur is present in Armenia, Poland, Saudi Arabia Scotland and Spain.

Key figures 2015: € 1.6 billion in net sales, 10,000 communities under contract, 12,000 employees and 18 million people served in France and around the world.

For further information, please contact FLEXIM: info@flexim.com, www.flexim.com