These pumps can be used in the water industry, the drinking water sector, reverse osmosis and marine application. They are specially designed to be consistently durable, and to function in such a way that the need to replace wearable parts is kept to a minimum.

Their robust structure is resistant to mechanical stress, thanks to specially designed dimensions which allow for especially high performance and operation stability up to 100 bar of pressure.

Efficiency at the B.E.P, ensured by optimized geometry in the blade profiles of the impellers and diffusers, is one of the series’ biggest strengths. Furthermore, wear is reduced to a minimum due to the fact that the hydraulics are equipped with an axial thrust compensation system.

The sizes of the hydraulics which make up the PM Series cover a wide range of flow rates and are available in CAST IRON, STAINLESS STEEL and DUPLEX.

It is exactly these PM machines, built for high pressures up to 100 bar, which benefit from the new size 65 hydraulic models. Depending on how the pump is going to be used, either a packing seal or a mechanical seal can be selected. The mechanical seal guarantees perfect regulation and protection against leakage, while the packing seal boasts superior ease of assembly and maintenance, reducing the risk of machine downtime.

The H version PM_65 with 4 poles is the configuration which allows for use with superheated water at temperatures of up to 120°C – though it is necessary to carry out checks on the 2 poles depending on the conditions the pump will be used in. The materials selected here guarantee durability even in such thermally heavy duty operating conditions. Vibration propagation is minimised in a great deal of operating conditions. As a result, barely any noise is created, which is a vital benefit especially when placing several machines at the same site.

Such reliability, top performance and versatility are the fruits of a great many years of experience in engineering, construction and application in the most diverse fields of use.

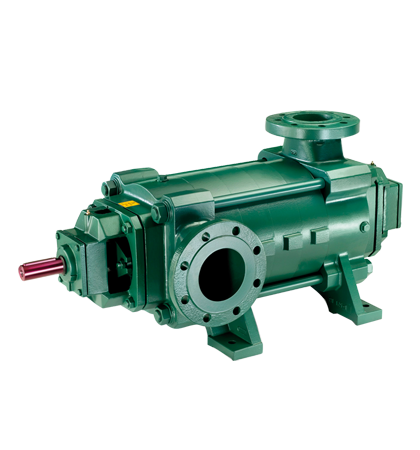

Horizontal Multi-Stage Pumps

- Up to 100 bar of delivery pressure

- Metallurgy construction to guarantee high performance

- Reliability and low costs with regards to both operation and maintenance

- High hydraulic efficiency

- Wide flow rate capacity