With the new developed series, 190 ARCA Regler completes the product range of control and shut-off valves for the steam turbine periphery, but also for various other applications.

Due to the rapidly increasing requirements especially in power plant technology (higher steam or condensate temperature as well as an increasing number of regular temperature changes), valves in such service will suffer high stress – inappropriate design or material selection (especially on cast components) could lead to early failure of the valve with impact to the availability of the whole plant.

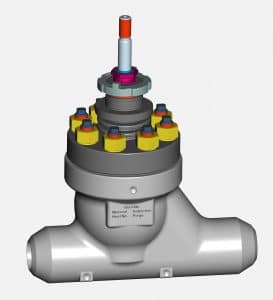

For this reason, when designing the new series 190, as a matter of principle the pressure containing parts (valve housing and bonnet) have been selected to be dye-forged parts. This manufacturing process guarantees a very homogeneous material structure without any discontinuities. Such microscopic defects, which are very difficult to prevent and to evaluate especially on cast materials, may lead to incipient cracks under hard mechanical or thermal alternating load and with this to early failure of the valve.Additionally, most advanced CDF-technology was used to optimize the design of the valve body to avoid tension peaks resulting from sudden temperature changes.

The valve trims are correlating to the well-proven ECOTROL®-system:

- Easy maintenance by exchangeable, clamped seat ring; means no seat thread requiring special tools.Parabolic or perforated plugs in a wide range of rated flow coefficients; with equal-percentage or linear characteristic

- Seat retainer optional in low-noise design

- Metal seated, seat leakage either FIV Class IV or Class V

The valves are delivered with butt weld ends per EN 12627 or ASME B16.25; with pipe outside diameter from 33,7 mm up to maximum 76,1 mm. Optionally, socket weld end or threaded connections are available.

The series 190 product scope are globe and angle style valves in standard materials as follows:

- 1.0460 / A105

- 1.7383 / A182F22 CL.3

- 1.4903 / A182F91

Each of the materials has double-certification to EN and ANSI Standard; means that valve housings from stock can be delivered into PED-range (up to PN 400) as well as into ASME/ANSI range (up to Class 2500; optionally available as “special class” valves with extended pressure/temperature range). With this, a wide application range and a high availability can be guaranteed.