For example, its hygroscopic nature is ideal for drying synthesis gases in the chemical and petrochemical industries. In most applications a very accurate monitoring of the sulfuric acid concentration is required to ensure an excellent product quality.

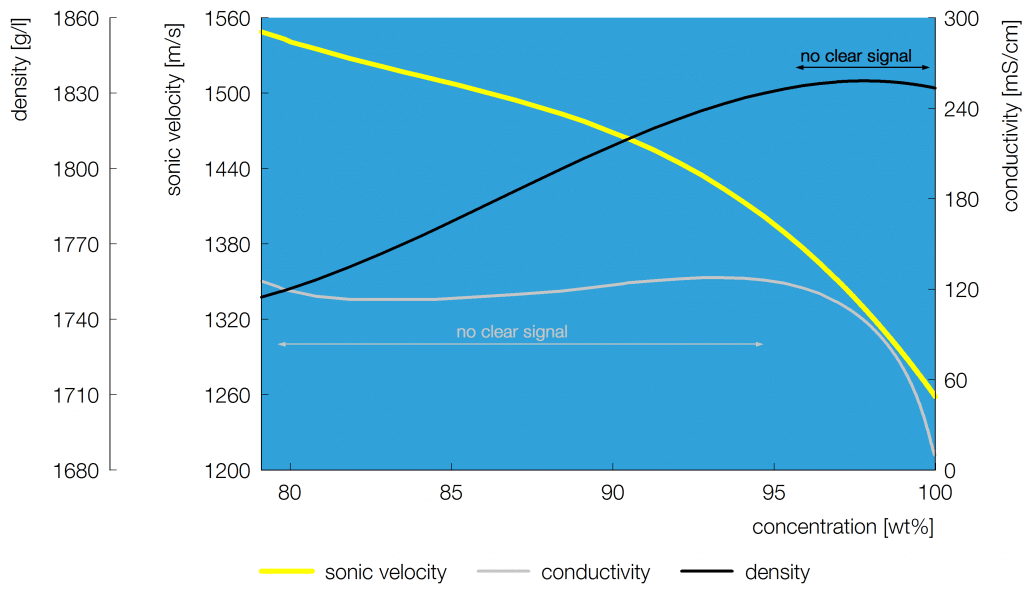

With the high sensitivity of sonic velocity to sulfuric acid concentration, the LiquiSonic® sensors achieve an accuracy of ± 0.05 wt%. The measuring principle of sonic velocity is well-suited to monitor the concentration of sulfuric acid. Figure 1 shows that conductivity and density measurements won’t bring up clear results between 80 – 100 wt% H2SO4.

SensoTechs rapid, robust sensing technology improves asset utilization, process safety and product yield. For aggressive process liquids special materials are available, like Hastelloy C-2000 or Tantalum.

The systems consist of one controller and 1 to 4 sensors (figure 2). They are plug & play, maintenance-free and work without moving parts. This ensures long-term stability. The LiquiSonic® analyzer can easily integrate into the process and reduces manual laboratory measurements, saving labor and material costs.

To enhance process control and safety LiquiSonic® systems provides many benefits:

- easy, user-friendly installation (plug & play) and operation

- excellent long-term stability

- one sensor for all applications (reduced investment costs)

- comprehensive diagnostic capabilities

- suitability for all needed concentration ranges with high accuracy

- conductivity and density show inflection points

Typical applications for LiquiSonic® analyzer measurements of sulfuric acid and oleum concentrations are: H2SO4 and oleum production, fertilizer production, synthesis gas drying, etching and pickling baths, mine-ore processing and refinery catalysis.

Result

SensoTechs real time inline concentration analyzers are the optimal way to monitor sulfuric acid processes in any kind of industry. They are capable of measuring the entire range of sulfuric acid and oleum.