Crucial to ensuring the expected levels of operation are the air-operated double-diaphragm (AODD) pumps used to transfer liquids through the manufacturing process. Therefore, it is imperative that these pumps are able to reliably meet their required demands. This makes monitoring AODD pump performance a critical consideration for facility operators, but oddly enough, the AODD pump is typically not the subject of a preventative maintenance plan.

Rather than following a tightly considered maintenance plan, AODD pumps are often allowed to run until failure, with the operator hoping nothing bad happens – product leakage that leads to costly cleanup, safety hazards, and loss of product and, by extension, revenue – before the pump actually stops operating. Or, the manufacturing-facility operator may decide that the AODD pump’s wear components (diaphragms, gaskets, balls, ball seats) will be replaced after a certain period of time – say, 12 months – no matter how they are performing. In this case, the wear components may still have many more months of life in them, so replacing them at this time can result in excessive maintenance costs, downtime and product loss, and an oversupply of parts.

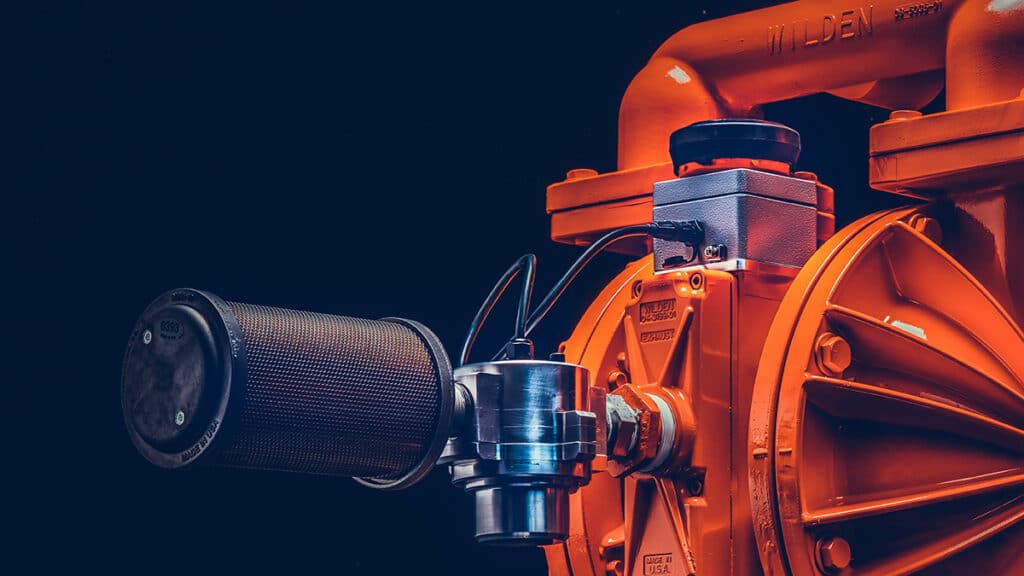

While this remains standard practice at some manufacturing facilities, many operators have begun to develop effective preventative maintenance plans for their AODD pumps thanks to the new Wilden® SafeGuard™, the industry’s first AODD Internet of Things (IoT) enabled remote performance monitoring and alert system. Using embedded communication technology to share an AODD pump’s operational intelligence, Wilden SafeGuard enables the quick identification of operational inefficiencies within the pump’s performance sooner and more reliably, creating real-time operational transparency and significant cost savings for the operator through continuous 24/7/365 Cloud connectivity. It is a true game-changer in optimizing AODD-pump performance, reliability, and cost of operation and maintenance.

Wilden SafeGuard is an all-inclusive pump-monitoring system that tracks, records and alerts customers to key performance indicators of AODD pumps at all times of operation via cellular access. The Wilden SafeGuard system consists of a battery-powered stroke sensor and transmitter (called an Edge device) that is installed on the pump. The sensor collects and analyzes pump performance data in real-time and transmits it to a central gateway for encryption and transmission to the Cloud. Once stored on the Cloud, real-time and historic operational information can be accessed by the user anywhere in the world through a secure smartphone app or an online portal.

Anticipating potential failure conditions is not the only benefit of remote diagnostic technology. Since pump performance is likely to change over time, whether by normal wear or through outside system influence, monitoring indicators such as stroke rate or stroke count can be an invaluable tool for the operator. Any variance can be noted and recorded, letting the operator know if a failure may be imminent or if a proactive maintenance check may be needed.

The design and operation of the Wilden SafeGuard system allows for complete monitoring and real-time alerts related to a number of critical performance parameters for the pump (diaphragms, balls, seats). These readings can show the user such things as:

- Leak detection to indicate diaphragm leaks and failures, preventing product loss and safety hazards

- Stroke rates to monitor changes to highlight performance abnormalities

- Stroke count for batching and setting maintenance schedules

- Real-time alerts via SMS or email to indicate any noteworthy change in operation that may be a precursor to pump or component failure

While it may still be considered a “new” practice for some facility operators, developing a comprehensive preventative maintenance plan for AODD pumps has never been easier thanks to Wilden SafeGuard’s cutting-edge remote diagnostic performance-monitoring capabilities. This new digital, Cloud-based pump-monitoring system uses next-generation diagnostics to give AODD pump users the ability to know exactly how – anytime and from anywhere – their pumps are operating and if any performance-related issues may be threatening, resulting in an operation that maintains the highest levels of efficient performance and safety.