Managing over half a million tonnes of waste per year in Yorkshire, Yorwaste brought in Phoenix Engineering to carry out detailed process studies, and then to design and construct a major refurbishment of the treatment plant, originally built in 1990. This included the enhancement of a challenging oval-shaped lagoon, which during the winter months was not achieving sufficient biological treatment efficiency.

Jonty Olufsen, Managing Director of Phoenix Engineering, explained:

“We designed a new lagoon arrangement to focus on treating higher strength leachates within the landfill, which were a problem for the previous treatment plant system. During the winter, the existing mechanical floating aerators meant the lagoon could only operate at around 5 degrees C, when to achieve the most effective biological treatment, it should have been more like 20 degrees C”.

He added: “It is a complex application due to the oval shape of the (1400m3) lagoon. We worked long and hard with Landia to find the best way to heat the biological mixed liquor and keep it warm during the winter months. It was imperative that the contents of the lagoon would be aerated and mixed properly”.

Comprising a Landia Chopper Pump and venturi nozzle, four Landia 18.5kW AirJets were installed to providethorough mixing and aeration. With its effective knife system, the Landia Chopper Pump ensures that the aerator does not get clogged due to contaminants in the leachate.

During the settlement period of the leachate treatment plant, any movement in the lagoon had to be stopped as quickly as possible before the start of the next cycle to ensure suitable time for settling.

So, in the 42m x 24m (approx.) lagoon, a 3kW submersible propeller mixer from Landia was also installed. This small mixing unit runs for just a short time – only starting up when the AirJets stop. Aimed against the flow, the propeller mixer’s job is to act as a brake, slowing down the movement in the lagoon.

‘Consistent temperature’

Jonty Olufsen continued:

“With this combination from Landia, the result is that excellent three-dimensional mixing is in place. From the previously unsatisfactory temperatures of just 5 degrees C with the old mechanical floating aerators, a consistent temperature of around 20 degrees C is maintained throughout the winter, making the biological process very efficient.

The second lagoon (also 42m x 24m with rounded ends) has been converted for raw leachate balancing, allowing for controlled blending of incoming leachates. For both lagoons, full process controls have now been installed, with a new sodium hydroxide storage and dosing system for pH control.

Previously, the plant was predominantly a manual operation, with very little process automation or data acquisition or recording, and no automated pH control option. Now though, as Principal Contractor, Phoenix Engineering’s full design and refurbishment has seen the installation of a complete new electrical control and automation system with control building, remote IO and control panels. All new process instrumentation was fitted, with the whole plant now linked back remotely to Phoenix Engineering’s DLOG (digital logbook).

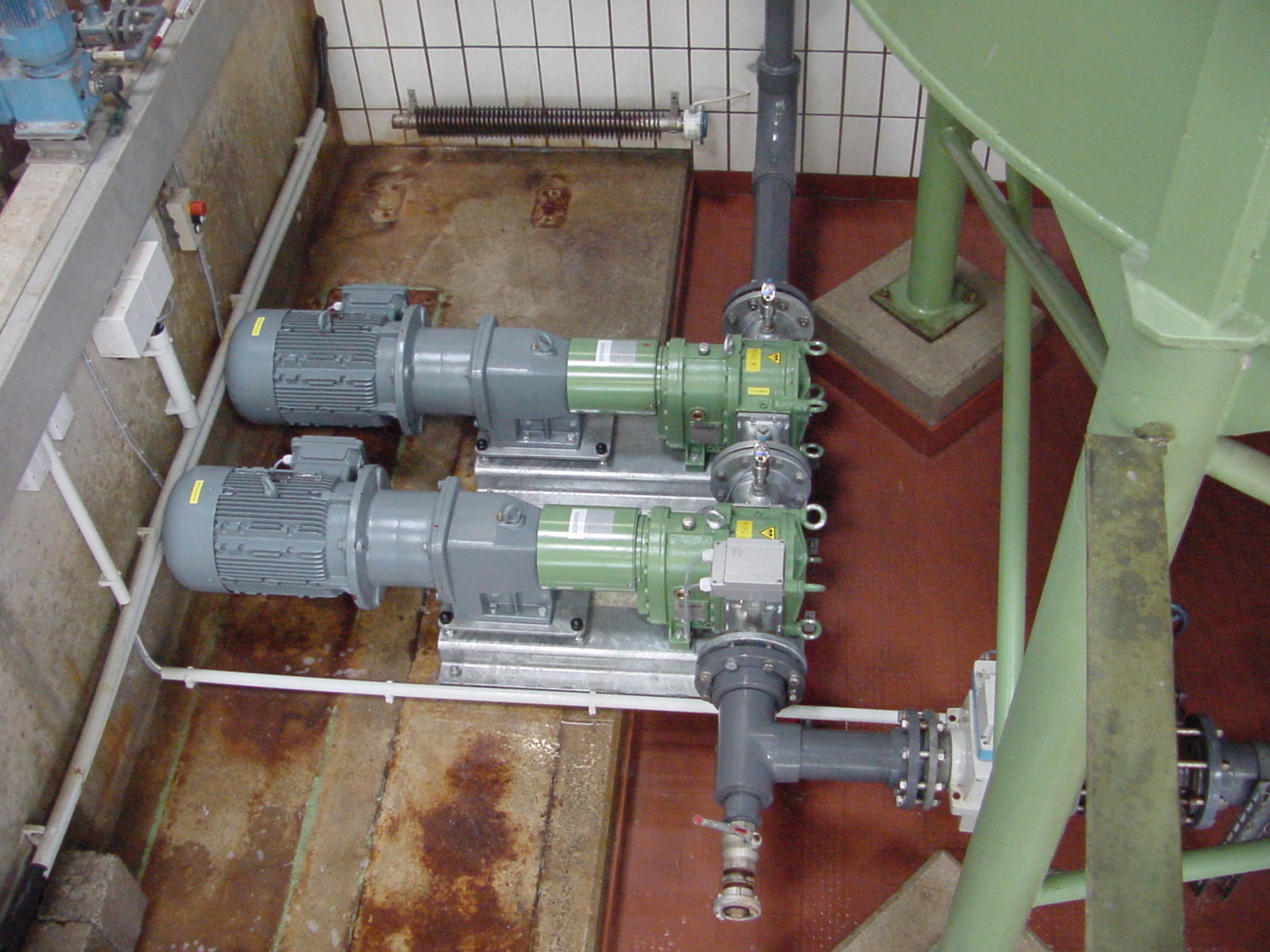

Seed sludge from a number of leachate treatment plants around the country was sourced by Yorwaste, with support from Phoenix Engineering for biological commissioning towards the end of 2019. The two companies also worked together to source and deliver new duty/standby pump skids – fabricated, built, and tested at Phoenix Engineering’s workshop, then delivered and installed on site – as was a new gantry arrangement for access to, and to support new control panels, instruments, and aerators.

‘First-class refurbishment’

Speaking for Yorwaste, Callum Duff, Landfill Restoration and Aftercare Manager, said: “As well as ensuring that we recycle and recover as much as possible of the material we collect, we also take our responsibility to the environment seriously, so we carried out a lengthy search for the right people to partner with for the upgrade of our Harewood Whin Leachate Treatment plant”.

He added: “From start to finish, Phoenix Engineering worked with us to deliver a first-class refurbishment. With the Landia aerators and mixer, they have shown their keenness and capability to ensure that the leachate is treated with optimum efficiency”.