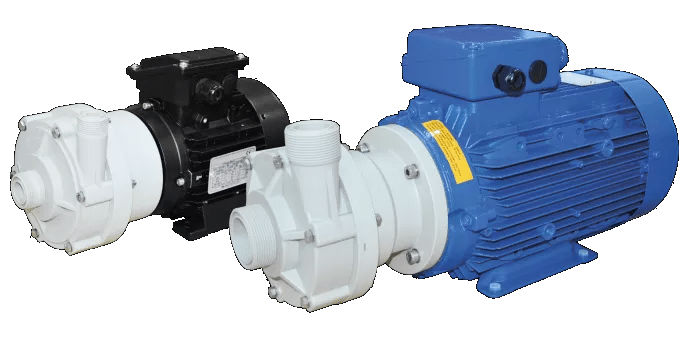

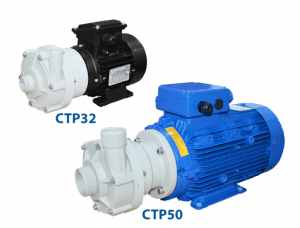

Tapflo, the leading supplier of air operated diaphragm pumps, centrifugal pumps and other industrial process equipment, has announced today a new product range for a surface treatment industry. The company has launched a plastic version of its CT centrifugal pumps family – the CTP Pump. This portfolio update will allow to cover even more applications with Tapflo product range.

New Tapflo CTP pumps are available with BSP thread, flange or hose connections. The pumps can be used for chemically corrosive and toxic liquids as well as for clean and thin liquids like pure chemicals, acids and alkalis because the wetted components are non-metallic, injection molded thermoplastics enabling excellent corrosion resistance.

The version in PP-GF (glass fibre reinforced polypropylene) provides great mechanical strength and allows liquid temperatures up to 70°C. The PVDF (PolyVinylidine DiFluoride) version has superior chemical resistance and allows temperatures up to 80°C – 90°C. – explains Mikolaj Laguna-Horodniczy from Tapflo Marketing

The Mechanical seal is located on the dry side of the pump and is protected against contact with the liquid. In addition the, as standard, the spring is made of Hastelloy C which increases its chemical resistance in the unlikely event of a leakage. What characterizes our new plastic pump from is that the pump is equipped with a drainage option, which is designed to protect the motor against contact with any aggressive medium. CTP pumps allow pumping solid particles up to 3 mm in size and 10% in concentration. What is more the pump can handle metallic particles.– explains Jakub Zduńczyk Product Engineer at Tapflo

New CTP pumps form Tapflo can be used in various applications: transfer of various chemicals from storage tanks to smaller containers, transfer, filtering and circulation of surface treatment baths, pumping of CIP detergent used for cleaning of pipes and other food process equipment, Dosing of acids and alkalis used as cleaning chemicals in Nano filtration, just to name a few.