The latest technology in dewatering pumps plays a vital role in addressing these needs by delivering solutions to key factors such as reducing downtime, improving serviceability, reducing emissions, legislation, and ensuring the pump is properly sized to operate most efficiently.

Decreasing downtime

Downtime is a significant contributor to productivity and sustainability. Reducing downtime means operators can work to maximum performance levels and improve operational efficiencies. There are two types of downtime: unplanned downtime, whereby a part fails, and the job needs to be stopped to repair the equipment, and predicted downtime which takes place for routine servicing and maintenance.

There are several ways downtime can be reduced. The first is to ensure the equipment is appropriate for the job at hand and robust enough to withstand the applications’ operating conditions; this will prevent premature failure. Also, ensure the equipment uses high-quality parts, it will work as expected and continue to run reliably with an optimum mean-time-to- repair (MTTR).

Other pumps designed for maximum uptime, Atlas Copco’s WEDA range of electric submersible pumps, has been built with a special Wear Deflector technology. Incorporated in the D70 variant initially, this innovative hydraulic design has resulted in an extremely durable pump that offers long-lasting performance under tough operating conditions. Solids suspended in water can cause an impeller to wear and prematurely fail. However, the unique Wear Deflector protects the hydraulic components of the pump from sand and other abrasive particles.

Improving serviceability

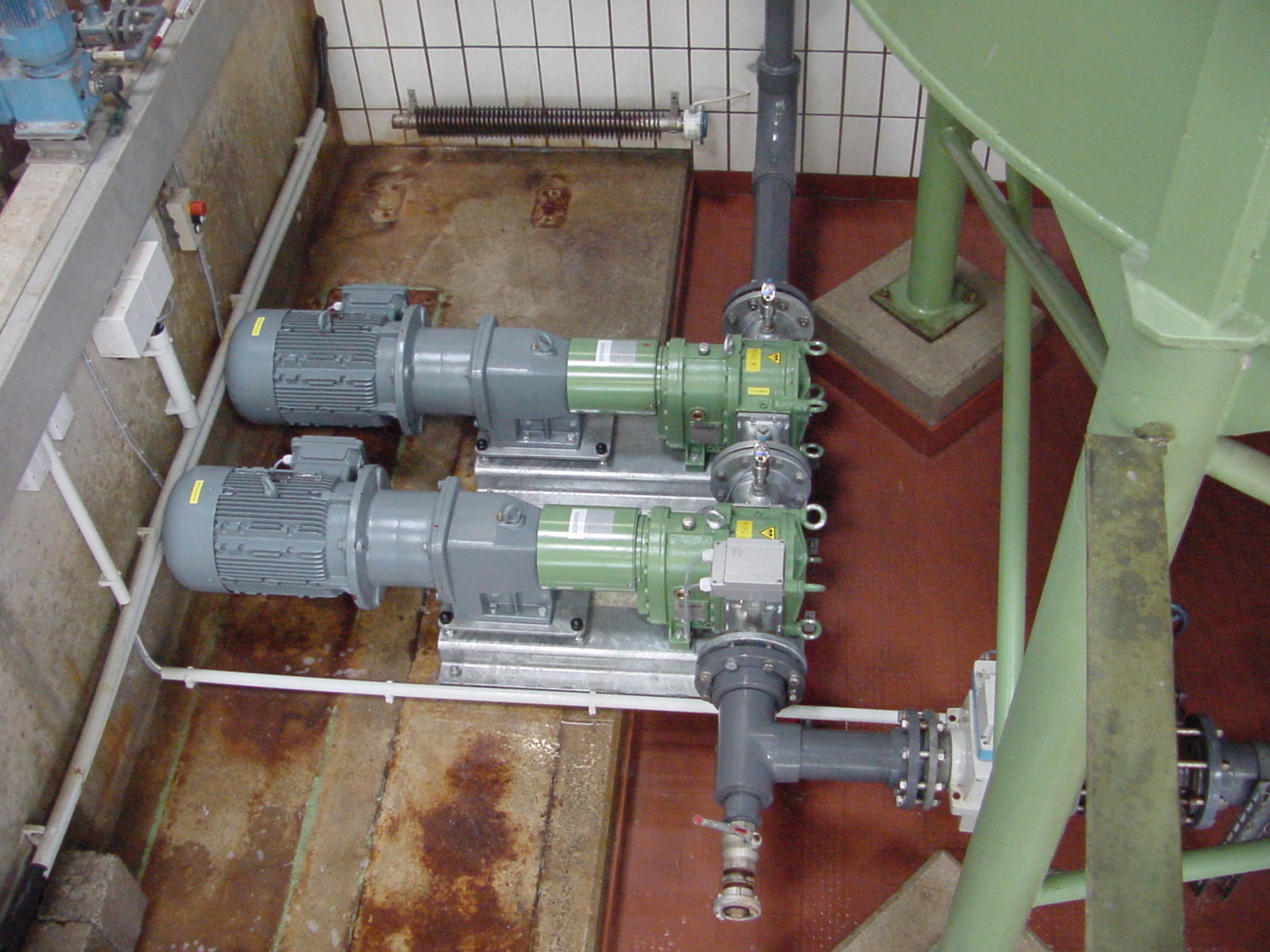

Downtime associated with regular maintenance can be reduced with equipment that has been designed to be easy to service. Features such as hinged doors offer quick and easy access to a pump’s internal workings for fast serviceability. Ease of maintenance can be enhanced with design features such as the semi-cartridge seal design on the PAS and PAC pumps, which allows seal access and replacement from the front without dismantling the pump.

The PAS HardHat® range incorporates these features and can be cleaned and restarted in just three minutes and serviced in under 60 minutes. Digital technologies, like Atlas Copco’s FleetLink, can help improve monitoring and assist operators to work more efficiently as it enables remote monitoring of pump performance and condition, providing the operational insight needed to optimize pump usage and maintenance.

Increasing efficiency

Carbon footprint can be reduced by considering the energy source of the pumps as well as adhering to the European Stage V emissions regulations that specify a limit for particle number emissions from diesel engines.

If electricity is available, an electric pump can be an efficient choice. Electric submersible pumps – such as the WEDA pumps – are the most energy-efficient, providing high power in light and compact packages. Atlas Copco has developed a handy sizing calculator for WEDA pumps. By simply entering some key technical information such as flow, static head, hose/pipe length, and diameter, the calculator provides operators with the most appropriate pump for their operation.

The PAC and PAS surface pump ranges are completely EU Stage V compliant. They are also certified to work with biodiesel Hydrotreated Vegetable Oil (HVO). This fossil-free fuel is the newest and cleanest generation of biodiesel, produced from recycled vegetable oils and fats. Additionally, PAS and PAC pumps feature an innovative electronic engine for more efficient operations.

The E-Pump range, which comprises the E PAS and PAC electric models, offers an exciting electric, reduced CO2 emission alternative to diesel-powered surface dewatering pumps. This allows customers to reduce their emission footprint and operate in emission-restrictive areas with no fuel consumption when the pump is working. This range is quick and easy to install and has a tremendous impact on the overall productivity of the units, lowering the TCO compared to their diesel counterparts and ensuring high performance for longer periods of time.

Sizing for a sustainable future

The final way to improve efficiencies is by having the correct pump size. By using the right pump for the job, operators can remove water and sludge more effectively.

For the best value and efficiencies, consider the technical parameters and requirements. The pump selected should be able to handle the flow requirements with enough capacity to cope with fluctuations in water level as well as versatility to manage the demands of different sites. An oversized pump that can handle a much higher flow capacity than needed will be unnecessarily expensive; without providing the most cost-effective solution. On the other hand, a pump that has been under-specified will struggle to transport the fluid and wear out more quickly, resulting in a shorter life span.

Pumps are an essential piece of equipment on any project, and when considering the efficiency and sustainability of a whole operation, they are a critical component to review. Working with trusted partners and manufacturers that can offer an extensive range of pumps designed to help operators reach their goals is key.