The need that Burnett Lime had was to deliver the key ingredient, containing a very high solid content, in the process, with a high accuracy and avoid failures that are common with these types of slurries.

The Challenge – High Solid Content Slurry

Burnett Lime Co. Inc. is an industry leader in pH control process technology, reinventing water treatment and industrial processes through a range of patented innovations. They use a lime slurry to control pH which presents a challenge that is common to many operations who rely on pumping slurries.

High solids content can plug orifices and collect in critical areas, such as near the moving diaphragm. A buildup around a diaphragm can cause a pinch point, which would ultimately lead to a diaphragm failure, leading to an outage and maintenance. Solids can also prevent check valves from fully seating which will cause irregular and inaccurate flowrates.

Accuracy Is Key To The Process

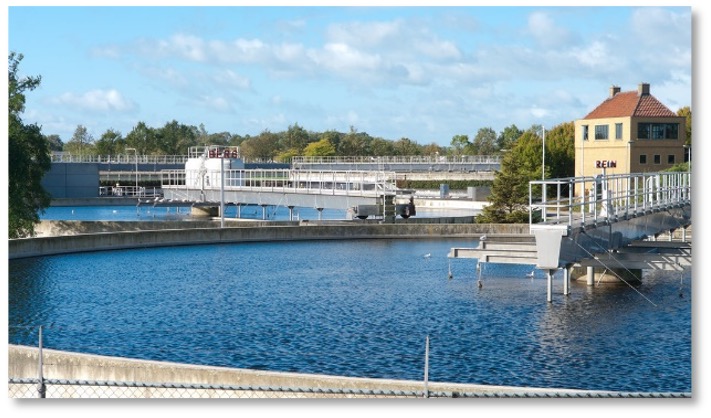

Accuracy is important when controlling pH in the treatment of water and wastewater. If the pH is too low (acidic) or too high (caustic), it will inhibit the growth of beneficial bacteria. This healthy bacterium is crucial for the process to enable the aerobic digestion and elimination of the biological content of sewage.

A diaphragm pump is built to maintain this type of critical accuracy but many of these types of pumps will suffer frequent process failures due to the buildup of debris in the pump.

The Solution: Pulsafeeder Hydratube

Burnett Lime Co. Inc. had previously used several different types of pumps including air operated double diaphragm (AODD) and peristaltic hose pumps. Dosing the lime slurry led to issues with these technologies as hose failures in peristaltic pumps were disruptive and messy and AODD pumps did not provide the accuracy required in this unique process.

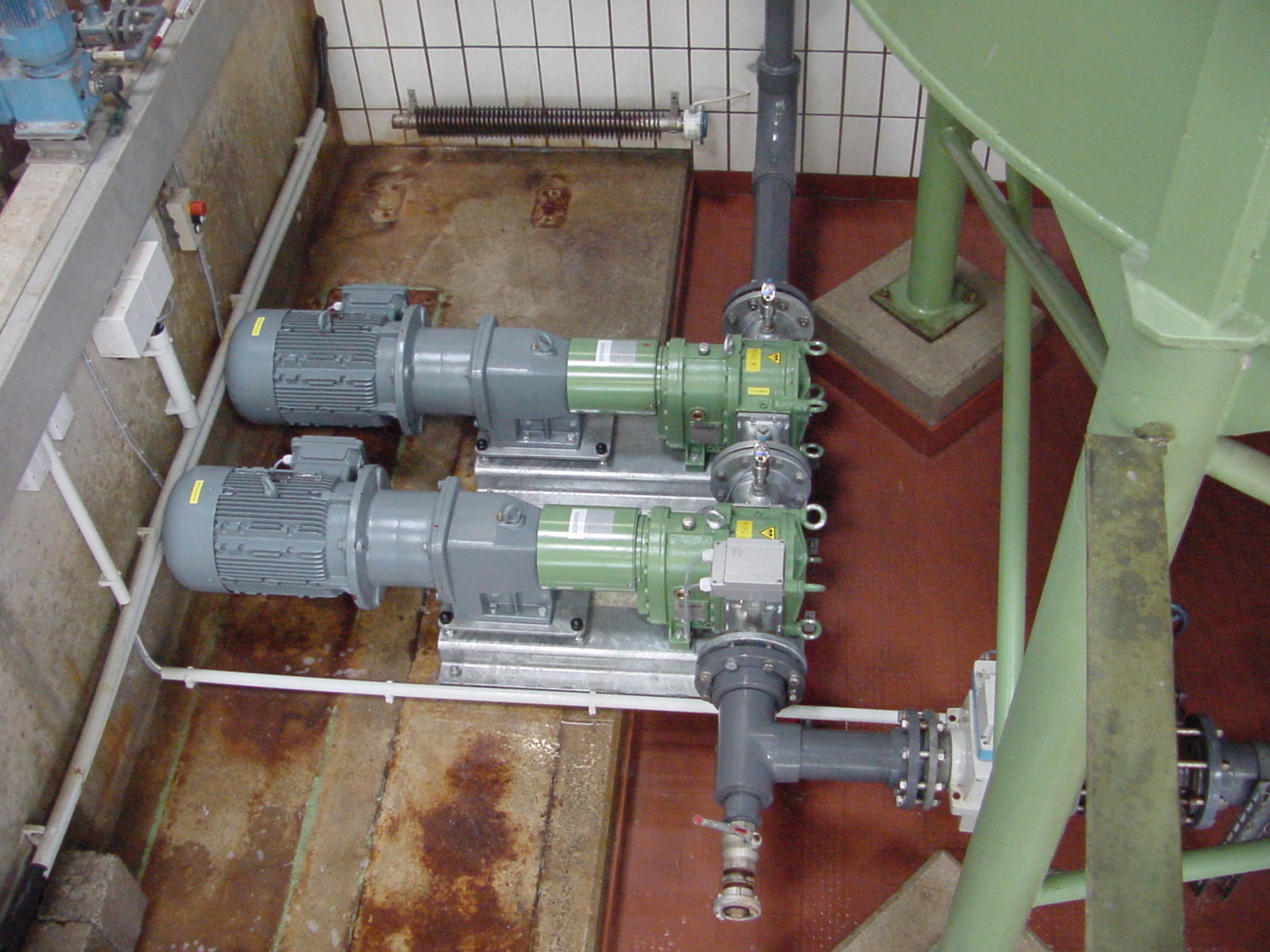

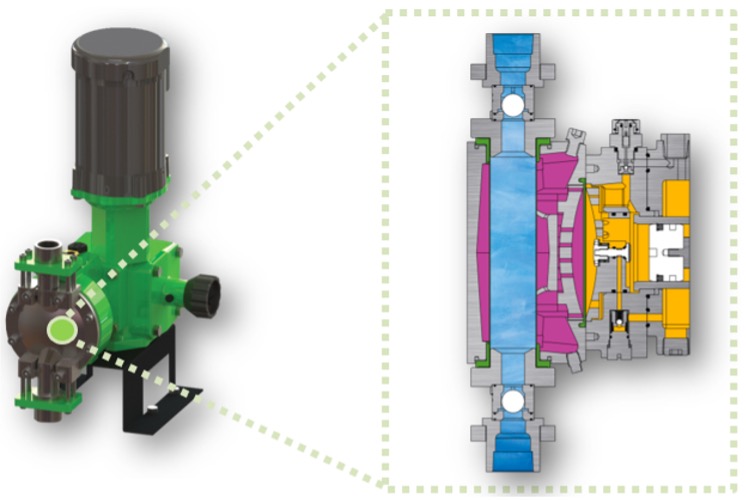

Pulsafeeder provided the solution in the form of a tubular diaphragm design branded the HYDRAtube®. The PulsaPro HYDRAtube® is the right choice for sheer sensitive, high viscosity fluids and slurries. Its straight, large, flow-through design eliminates clogging and flow restrictions that trouble other designs. By constantly flexing the diaphragm and moving the particles, the particulate does not collect on the tube diaphragm and does not settle into the places that could cause problems for operators. It also offers a double diaphragm safety which against messy rupture failures and optional slurry valves for integrated flow control, designed for this type of applications.

Reliability And Ease

Preventative maintenance is simple. Regular oil changes and observing the wet end of the pump for wear is all it takes. The check valves can be inspected without removing the pump from the system and the diaphragm integrity can be seen through the PulsaPro diagnostic window. If a diaphragm does rupture, the pump is hermetically sealed meaning no more messy hose failures. In the rare event of diaphragm rupture, the optional leak detection can alert the maintenance crew to the issue.

The Pulsafeeder HYDRAtube® has a straight, flow -through path that is ideal for pumping slurries with high solid content

Not only did the HYDRAtube solve the issues experienced with other technologies, but the original pump has been working in Burnett’s original system without fail since 1992.

The consistency and dependability of Pulsafeeder’s products over the years has been critical in keeping the customers satisfied.

Hugh Burnett – Burnett Lime Co. Inc

Solids are not unique to lime applications. They are seen in a variety of chemicals and applications across many industries. Magnesium hydroxide, diatomaceous earth, ferric chloride, or chemicals that precipitate solids as they degrade, are all potential problems for the traditional metering pump.

If solids are a problem for you, we may have a tubular solution.