With downstream and external pressures increasingly exercising their influence over how you manage your enterprise’s fleet of machinery, how do you adapt to these new influences?

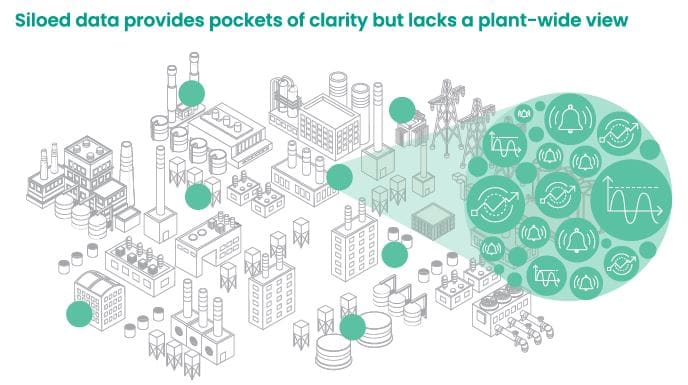

The first step in attaining the insights you need is to start from the top and look down. Without a truly all-encompassing, enterprise-level view of your machinery assets, how will you understand what is happening on a plant or site level?

The System 1 software platform can kickstart your digital transformation by empowering you and your personnel to do their jobs better than ever before. This, in turn, allows your machinery protection program to operate better than ever before, which in turn leads to increased safety, efficiency, and ROI.

Connectivity + Analytics + Visualization = System-Wide Insights

The formula for success in any digital transformation in a condition monitoring program starts with these basic principles, which are baked into the code of System 1. Some of the key benefits of System 1 are:

- Cyber Security

- More Data + More Insights = Better Decisioning

- Increased Connectivity

- Targeted, Actionable Analytics

- Advanced Data Visualization

- Seamless Hardware Integration

- Ease of Deployment

Making Digital Transformation a Reality

Any change comes with its own challenges and difficulties, but when you take an accurate and honest look at where your organization stands today, where your competitors are, and where you could be tomorrow, you will undoubtedly begin to see the value in undergoing a digital-centric approach to condition monitoring of all your machinery. Bently Nevada can be your partner in making your digital transformation a reality as we have with hundreds of other customer across the entire spectrum of industries.

If you would like to learn more about System 1, feel free to contact us to see what System 1 from Bently Nevada can do for you.

Editor’s note: this article is an excerpt of a larger piece on Bently Nevada’s System 1 Blog: Go System-Wide With System 1