A number of Life Cycle Analysis (LCA) studies have shown that aseptic filling techniques using ultra-heat treatment (UHT) systems, which are based on heat exchangers, generally have lower environmental impacts.2,3 This is down to two main factors: the packaging used in the two different processes and the energy footprint of the process itself.

Aseptic filling provides robust product quality, minimal thermal impact on the beverage, and greater bottle design flexibility with the ability to use lighter-weight PET bottles or cartons. In contrast, hot filling requires a higher energy requirement, has a thermal impact on the beverage itself, and has less flexibility of bottle design than aseptic filling.

Key difference between systems

In an aseptic (cold fill) system, the product is pasteurized or sterilized using UHT systems and then cooled immediately. It is then placed in the packaging which has either been pre-sterilized (or is sometimes sterilized at filling). Heat exchangers are generally used for both the heating and cooling processes, enabling very efficient heat transfer and the use of heat regeneration to minimize the overall energy requirement. In these situations, ‘considerable energy is saved by using the hot product’s heat to pre-heat the cold one, and vice versa.2

In a hot filling system, the product is pasteurized or sterilised (using heat exchangers or other thermal technologies). The packaging is then filled at a high temperature (typically between 80 and 92 °C) which has the result of sterilizing the packaging. The packaging is then tilted or agitated to ensure complete contact with the hot product and the temperature is maintained for a specified period, such as two minutes. After this the packing and the product are cooled. Typical methods include blast tunnels, falling water coolers or even cold storage.

Difference in packaging LCA

In practice there are many different types of packaging used in both systems, although in general terms board-based cartons and light-weight PET bottles are used with aseptic systems, while hot fill machines are associated with heavier PET bottles, glass or cans.

In an effort to accurately compare the environmental impact of both systems, some researchers compared aseptic and hot fill systems based on the production of 500 ml PET bottles of orange juice.2 Because a thicker gauge of plastic bottle is required to withstand the higher temperatures in hot filling systems, more plastic is used (in this example 24 g for hot filling versus 16 g for aseptic filling). As a result, the greenhouse gas (GHG) emissions associated with the packaging are 80.4 g CO2e per bottle for the hot fill process, compared to 61.8 g CO2e per bottle for aseptic filling – a saving of 23.1%.

Difference in energy consumption

The difference in energy consumption between the two systems is due to different heat treatment, filling and cooling methods have often been ignored by researchers. Studies have shown that ‘There are several advantages to aseptic processing and packaging over traditional pasteurization. Advantages include extended shelf life [and] lower energy costs.’3 Using heat exchangers with energy recovery provides significant energy savings.

Where the energy footprint of aseptic filling has been compared to hot filling techniques,2 it has shown that, ‘the product treatment in hot filling appears to have higher impacts die to the higher energy requirement that occurs during the warming and the chilling phases’ and, ‘in hot filling systems the heat of the treated product cannot be recovered.’

Using the same 500 ml PET bottles of orange juice example above, GHG emissions associated with energy consumption by the process were 31.6 g CO2e per bottle for the hot fill process, compared to 24.4 g CO2e per bottle for aseptic filling – a saving of 5.32%. While this may seem small, when applied to a theoretical production of 250 million bottles per year, this represents a saving of more than 1,500 tonnes of CO2e each year. Based on our experience of thermal processing systems around the world, at HRS we believe that the GHG impacts of hot filling technology are in fact higher than this.

The combined effects

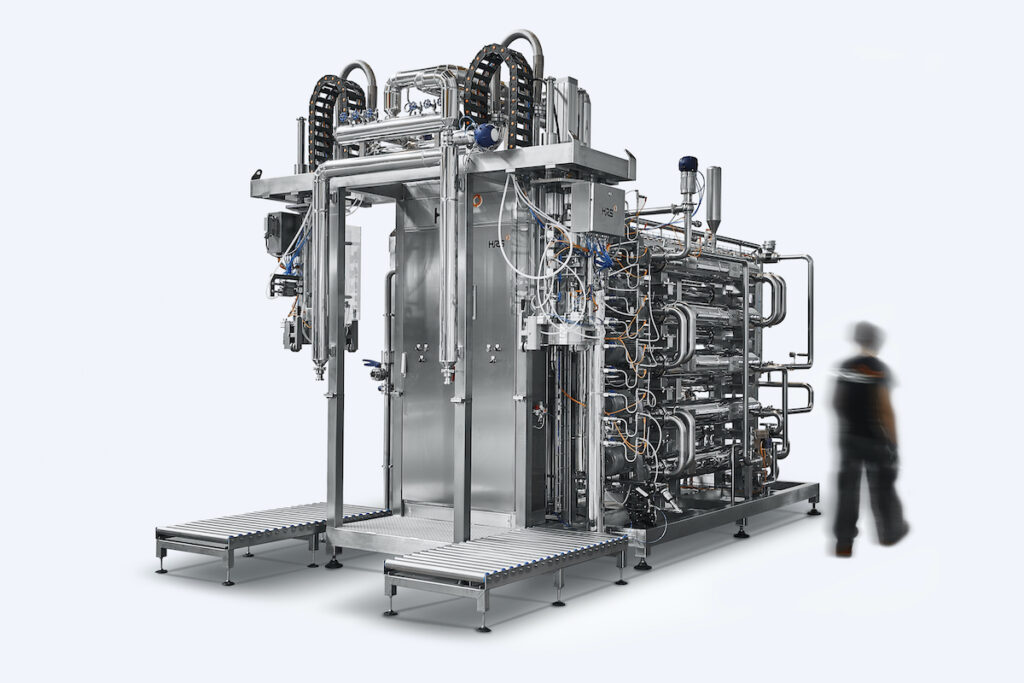

As the scientific studies above show, overall GHG savings of 24.9 g CO2e per bottle are possible, something that is far from significant. To discuss how the HRS range of heat exchangers, pasteurization and sterilization technologies, and complete aseptic treatment and filling systems, can help your business to realize these monetary and environmental savings, please contact us.