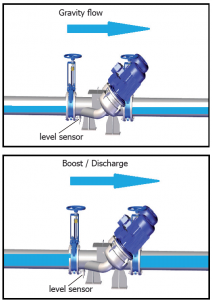

The DIP-Booster circulators by Side Industrie are derived from the high range of wastewater circulators DIP Systeme, but dedicated to pipes and not to lift stations. They are also made of boiler-plate stainless steel. They are composed of a shared hydraulic body that fits the pipe size, allowing the gravity flow to go through it. Includes a by-pass valve, a level sensor upstream and 2 variable speed hydraulic drives connected in parallel using VFD’s.

Operation

Gravity Flow: The flow goes through the DIP BOOSTER as long as it does not fill the pipe. The motors are off, the control panel leaves them on stand-by and continuously checks the level via the level sensor. The internal valve is open.

Water Level Rising: If the gravity flow fills the pipe and the DIP Boosters body the start-up level of the first motor unit is reached. It will start up slowly and then accelerate the flow activating the internal check valve. The second motor unit starts up if the upstream level increases. The motors stop when the upstream flow decreases back down to gravity flow.

Applications

- Pipes with insufficient slope

- Pipes undergoing periodic backups

- Accelerated in-line wastewater circulation – more velocity

- For a gravity-fed line of 6″ to 40″ diameters

- Savings on pipe diameters

- Where increased scouring is needed

References

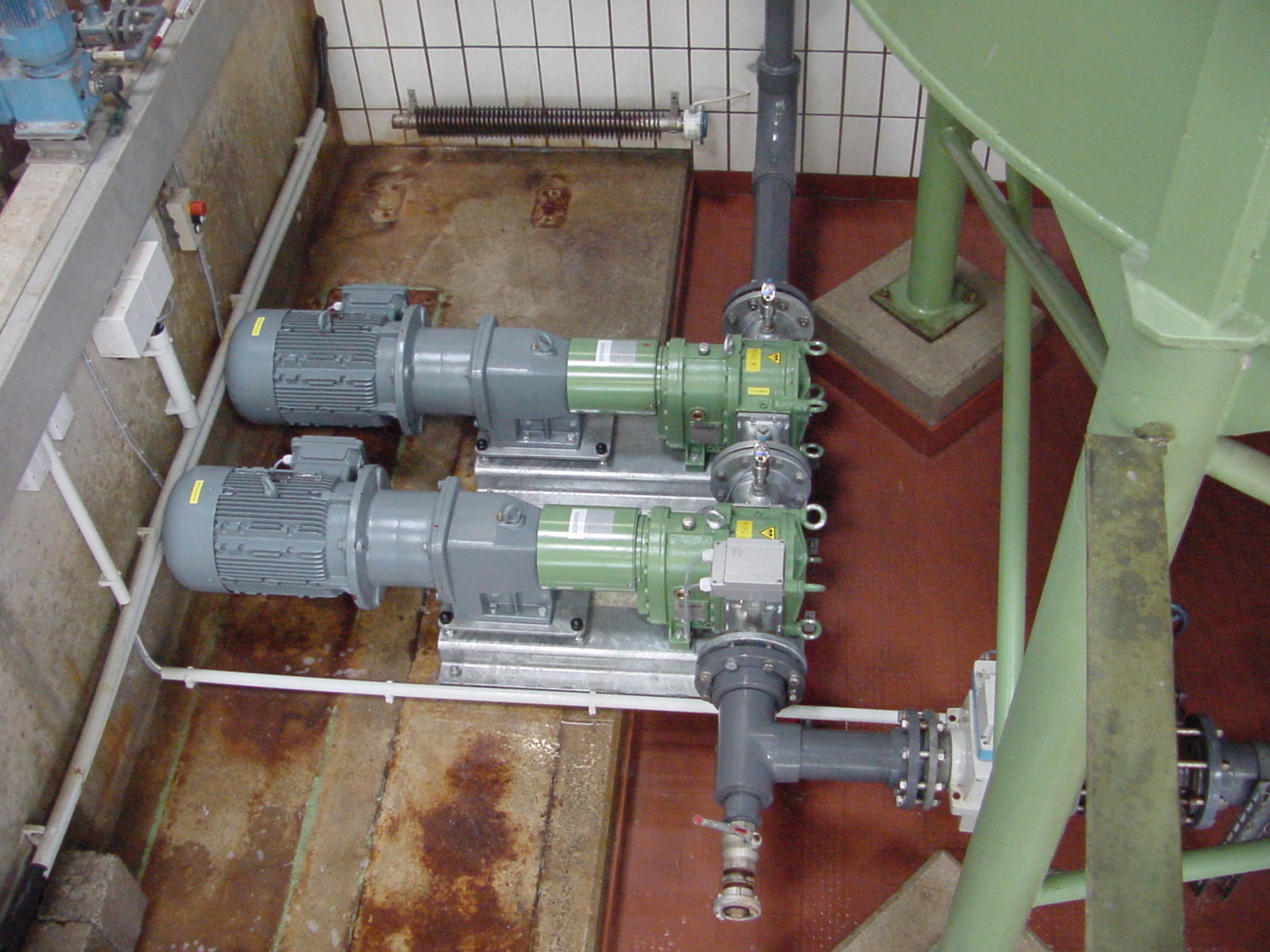

End of 2018, after 5 years of R&D, SIDE Industrie has launched worldwide the innovation DIP Booster. This innovation immediately convinced the international airport of Washington-Dulles that installed the first one on one of its pipe that had insufficient slope reducing its capacity. As well, last September, the water treatment plant of Achäres (in France), the biggest treatment plant in Europe, commissioned their DIP Booster 100B-6VV-3kW.

This DIP Booster has been implemented in order to boostly pump centrifugate water (clarified liquid) produced by two mobile centrifuges of 2.5 and 3.5 T MS/h.