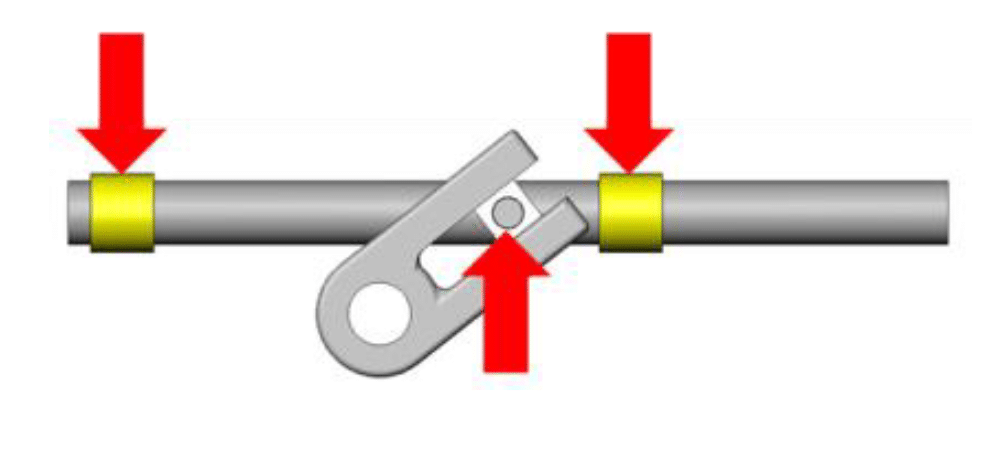

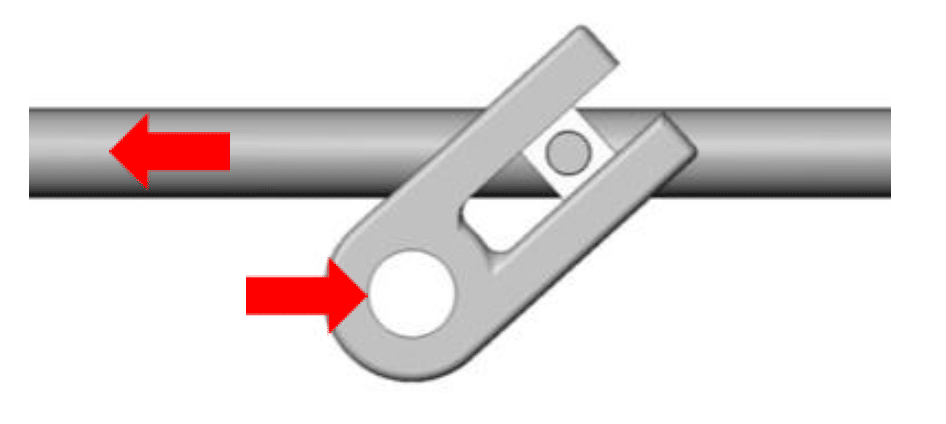

The lever is longer at the ends of stroke so that a given force results in more torque at the ends of travel than at the mid-travel positions. Additionally, the angular relationship between the input force and the lever also acts to increase the torque output.

(Double Acting)

A price to pay: The increased end of stroke torque does not come without penalty which is a very high side loading force acting on the rod.

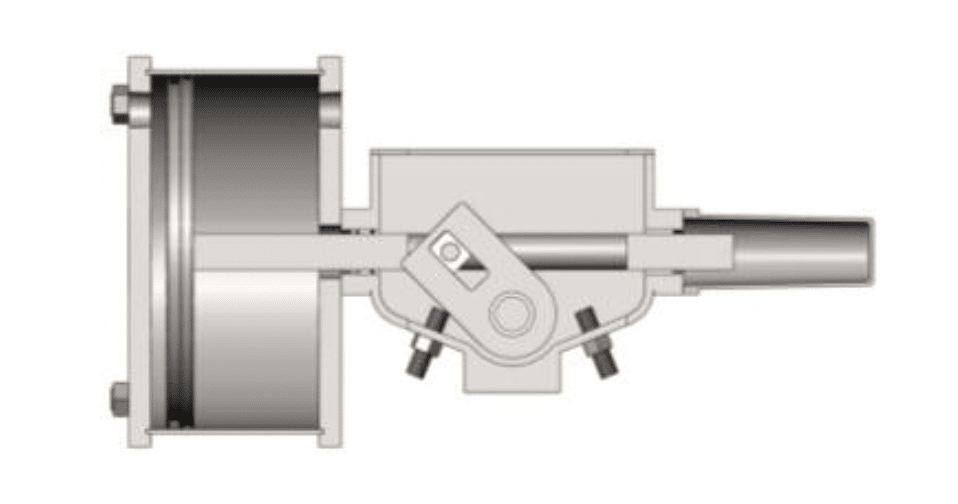

Traditional Scotch Yoke Actuators:

As demonstrated, the scotch yoke mechanism provides an ideal torque characteristic for many types of valves and as the valve torque requirements increase, the scotch yoke becomes a relatively lower cost design to manufacture.

Because of the side loading forces applied to the rod, designers must contend with how best to provide rod support. Lacking an alternative means, designers (and those that have copied them) extend the rod through the actuator body to obtain support from the bushings on both ends.

Traditional Scotch Yoke Actuators – Design Compromises

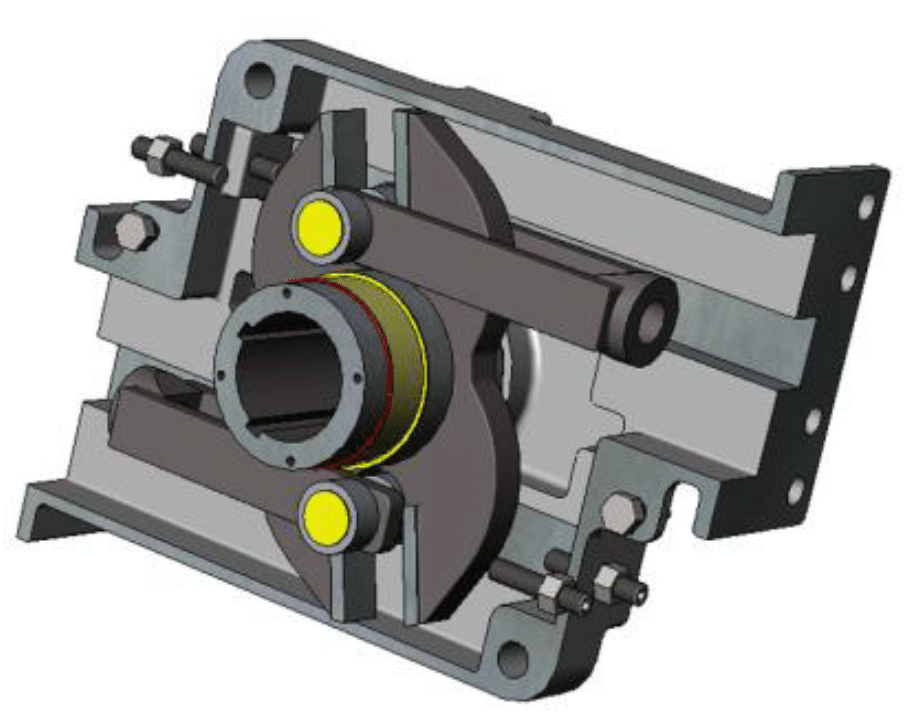

Because the rod does extend through the body, force module location is limited by available space to one side of the shaft axis. The spring module is located on one end of the body and the piston module on the opposite end.

Results:

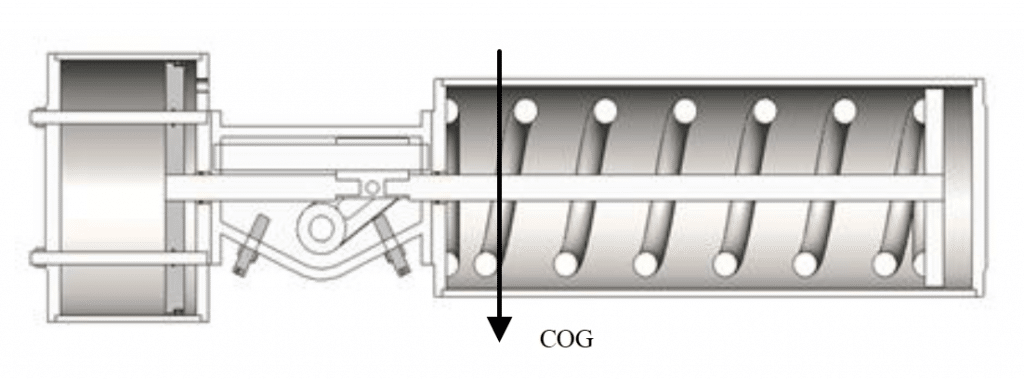

- Weight Imbalance – The center of gravity is offset from the shaft axis and it continuously relocates as the actuator operates.

- Force Imbalance & High Friction Losses – 100% of the piston and spring forces act upon the output shaft and the bushings that support the shaft. The shaft/bushing friction leads to wear and reduced output torque. For example, a 10,000 in-lb piston force is equaled by a 10,000 in-lb force acting on the shaft bushings.

Common Designer Induced Deficiencies

Proprietary Seals – Most, but not all, designer apply pressure to the body side of the piston so that the springs are compressed toward the body. One reason is that this permits lighter, lower cost piston end tie rods while the spring forces act inward toward the body, lessening the strength requirements of the spring module attachment.

Results:

- Seal Required Between Rod And Body – While most seals may be inexpensive for the manufacturer, they are often proprietary and for the user they normally are overpriced.

- Seal Replacement = Expense – To replace the seal additional costs include downtime, removal of the actuator from the valve and complete actuator disassembly by skilled personnel and the facilities equipped for this work.

- Reversal is Complicated and Time Consuming – Action reversal from fail closed to fail open therefore requires a complicated and time consuming interchange of the two force modules from one side of the actuator to the other. Often the force modules are attached to the body module via threaded rod, adding to the complexity of the attachment.

Design Commonality:

Although Scotch Yoke actuators have been produced for over 50 years, designers may have modified the attachment of the force module or changed the direction of pressure on the outer piston surface to the body side, true advancement has not occurred.

Perhaps the forces applied to the rod simply prevented true change. – Perhaps an entirely new design is required.

A Disruptive Technology

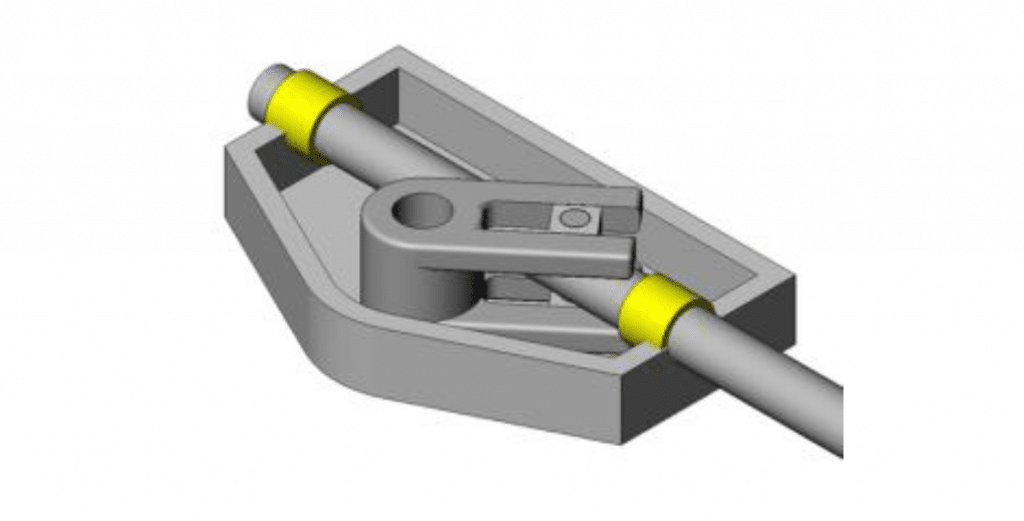

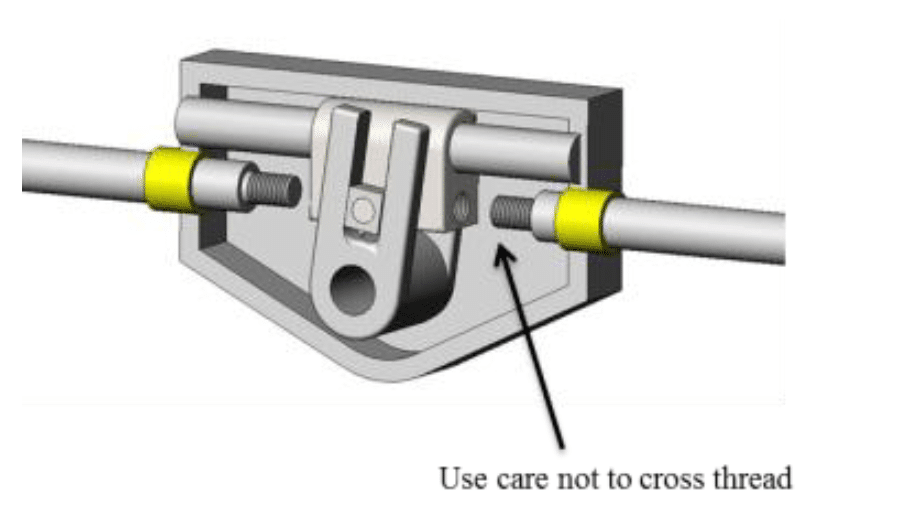

When designing the QTRCO Flat Yoke actuator, we selected the scotch yoke mechanism as the basis, but rather than copy existing actuator designs, we began with a blank sheet and no preconceived limitations.

If we could position identical force modules diagonally opposite one another on the body, there would be zero loads applied to the shaft bushings. Wear, friction and torque loss would be eliminated and the center of gravity would be on the shaft axis resulting in a balanced design.

It is not possible to fit two force modules diagonally on the body if the rod is extended through the body as with existing designs.

In response we developed an innovative slotted body design that transfers all of the side loading forces to the body, allowing the rod to terminate at the lever slot.

Result:

- Lighter, balanced weight with no side loading of the piston rod.

- Smaller, lighter, shorter springs

- Less wear

- No loads on the shaft bushings

- Greatly reduced friction

- Smaller pistons

- Increased torque output

Additionally, we rationalized that if the seal does not exist it cannot fail. Therefore, as proven with our Rack & Gear™ actuators, we located the springs inward of the pistons, eliminating all dynamic seals except the piston o-rings – which, with the user in mind, are non-proprietary, common, low cost o-rings.