The manufacturer of various dairy products needed a reliable solution to control medium solid waste from the plant’s effluent treatment process. The concrete tanks are 4 meters long and the material has the consistency of sludge with a DK value of 4. The pressure is in the range of 0.8 bar (11.6 psi) up to 5 bar (73 psi). There is no electrostatic charge. The process temperatures reach up to 80 °C (176 °F). Within the process hoppers there is a high degree of moisture and some build up. Accuracy as well as a quick response time were especially relevant to the process. Finally, the NivoRadar® 7100 was implemented into the wastewater treatment system. The certified sensors were configured using suitable manufacturing materials in accordance with the high hygienic requirements and safety levels. A high frequency signal is transmitted with a very small beam angle with two-wire technology. The signal is reflected by the slurry material and received back to the sensor. The frequency difference, which is directly proportional to the distance, is then further processed and output as the level signal. The sensor is ideal for use in water treatment tanks and, due to its design, is also suitable for acids and alkalis. It would even be possible for measurement to be made through the tank top of plastic containers.

Secure level measurement without blocking distance

In addition to the series of guided wave radar sensors NivoGuide® the portfolio of non-contact radar devices NivoRadar® has been expanded with the very compact radar series NivoRadar® NR 7000 and NR 4000. The extension of the non-contact radar series for continuous level measurement is equipped with 80 GHz FMCW technology and a very narrow beam angle. Due to its high frequency, response time of under 3 seconds can be generated. The installed NivoRadar® NR 7100 has been specifically designed for processes in the liquid sector. Thanks to its compact design with 1 ½” connection thread and intrinsically safe electronics, the sensor can be used for a wide range of applications. In this way, precise measurement results are achieved even in small containers. Resistant and robust synthetic materials guarantee long-term use, even in aggressive media.

The NR 7000 radar series also has flush antenna and potted electronics and is the right measurement solution for:

- Highly viscous liquids

- Strong caking, steam, outgassing and condensate

- Process and storage tanks up to 15 meters

- Moving surfaces

- Corrosive media

- WHG applications

The plant operator in Colombia was very pleased about the quick and easy installation of the non-contact NivoRadar® devices. With the PVDF wetted parts and high accuracy of +/-2 mm reliable measuring results are realized. It works smoothly in the demanding measurement conditions and suits also to the outdoor environments as it has ingress protection IP66/ IP67/ IP68. The sensors offer the manufacturer also an attractive price and are maintenance-free.

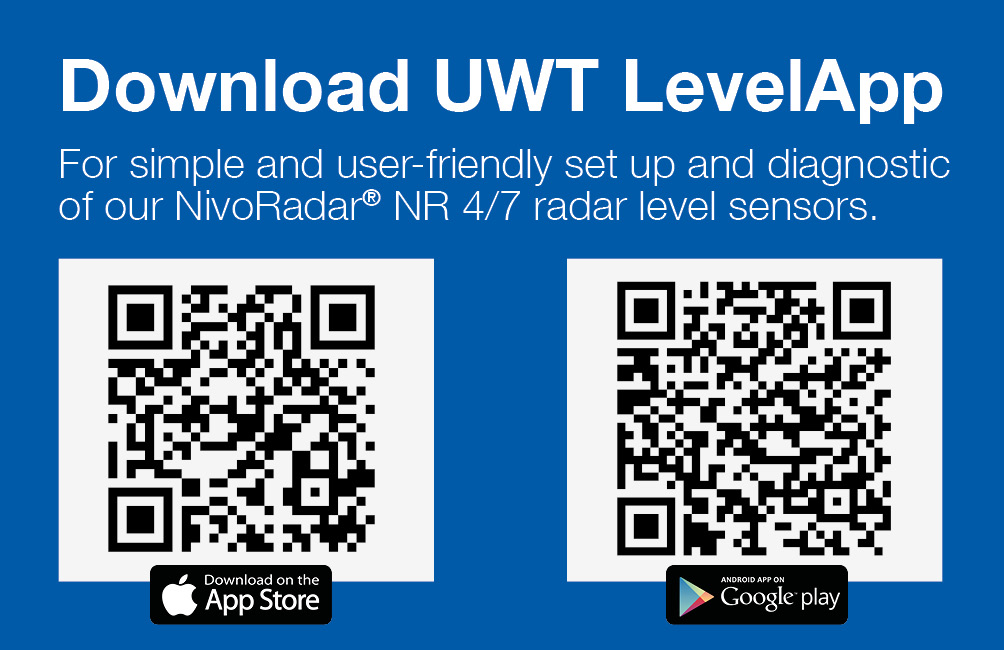

User-friendly all-rounder – control via UWT LevelApp

Using the UWT LevelApp the NivoRadar® sensors can also be configured quick and easy. The sensor values can be set or read directly on the device via the optional LED display. They work with a very high level of process intelligence and have a quick-start wizard. The aim in designing this particular device was to create maximum customer-friendly conditions with extremely simple handling.

Radar versus ultrasonic – when do you decide on radar?

Switching to radar is worth it. Radar is now both the cheaper and more reliable choice for continuous level measurement in a variety of industrial applications. The question is where ultrasonic can’t keep up and radar triumphs. In contrast to ultrasonic sensors, build-up on radar affects neither the precision nor the continuity of the measurement results. The blocking distance is also not increased in such scenarios. The non-contact radar series is consistently insensitive to dirt and does not require cleaning. Interfering factors on the antenna system caused by build-up can be masked out by optimized signal processing of the sensors. The NivoRadar® sensors of UWT are the latest level of non-contact measurement detection systems for solids and liquids. A wide range of mounting accessories and flexible temperature solutions enable this compact measurement technology to be installed in a wide range of industrial applications. The compact 80 GHz sensors work more precisely, are less affected by environmental influences and are a real alternative to ultrasonic technology in terms of price.

Get answers to the most important questions about the new non-contact radar sensor technology in the Expert Talk:

- What are the main features of the sensors?

- How can the settings be made?

- What about the blocking distance?

- What is the UWT LevelApp all about?

- What are the target markets and industries?

Our expert UWT sales and service team is here, ready to support you: sales@uwtgroup.com

The UWT quality promise: level measurement with guaranteed quality

The UWT Group is considered an expert for simple, safe and accurate level measurement, point level determination and interface detection in any type of bulk solids and liquids. The many years of success are based on the high quality of the products, innovative thinking and close cooperation with customers. That is why the company is the first manufacturer of measurement technology on the global industrial markets to offer a warranty extension to 6 years for all UWT sensors!

Plant builders and end customers around the world appreciate the customer-specific and user-friendly technologies of the German medium-sized company as well as the easy handling and longevity of the UWT sensors. With many years of experience, the company knows that high-quality and maintenance-free sensor technology is an important aspect for plant operators in all industries. The extended quality guarantee also offers manufacturing companies more planning security.