It is a passive flow-through device that requires no maintenance, nor requires any external power source or manual assistance to operate. Check valves rely on a flow rate or a differential pressure to operate without manual or automated intervention. One of the most important characteristics is the minimum pressure required to open the valve, the so-called cracking pressure.

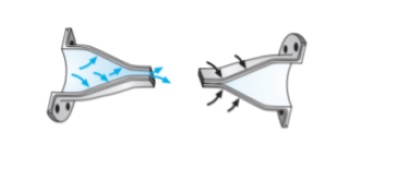

While some check valve designs are prone to corrosion, fouling, and erosion, the duckbill type is made of robust rubber or other elastomeric material. The duckbill valve is a flexible one-piece sleeve in the shape of a duckbill that disintegrates at the cracking pressure and closes again below this threshold. Any reverse differential pressure closes the valve tightly, preventing backflow. Duckbill check valves are non-mechanical, require no maintenance, and do not slam when closed. They are also resistant to organic contaminants such as algae and barnacles and have no problem disposing of suspended solids entrained streams, such as abrasive slurries.

Rubber duckbill check valves can be installed on pre-existing pipelines or grey infrastructure and are often used to replace existing valves that have proved inadequate. Due to their extremely simple design and robust construction, rubber check valves also require no maintenance and exhibit significant service life in the range of 35 to 50 years.

Prevent Backflow

By controlling and preventing backflow, check valves prevent discharges from wastewater treatment plants from contaminating clean water supplies. Check valves can also help prevent flooding, standing water, ensure water flows in the correct direction and prevent potentially harmful phenomena such as water hammers. In addition, check valves are widely used to control odors. They protect residential areas against the backflow of gases from, for example, sewers and wet wells.

Various rubber check valves are available that provide backflow protection against:

- Sewage sludge

- Rainwater drainage

- Water discharge to a river or sea

- Land erosion

- Stagnant water

- Salt and freshwater water (collection) basins

- Potentially contaminated water

- Numerous other uses.

Cost effective check valves for stormwater drainage

Stormwater management is an increasing challenge for water companies and municipalities as they seek to reduce the economic and health impacts of excess water. Changing weather patterns due to climate change lead to more intense events that increase the amount of rainwater entering water management systems. At the same time, increasing urbanization reduces the environment’s ability to absorb surface water. With impermeable surfaces such as sidewalks and roofs that prevent precipitation from drawing naturally into groundwater, water is increasingly drained into storm drains, sewers, and drainage ditches. However, the outdated drainage infrastructure can often become overloaded and as a result, poorly managed stormwater can cause flooding with backflow into residential areas. Such events inevitably lead to major problems. For example, flooding can cause erosion, turbidity from suspended solids, property damage, traffic disruption, and standing water.

There are also potential health and environmental impacts. In many urban environments, excess stormwater is drained into the existing sewerage system, where the network can become overwhelmed, resulting in the backflow and overflow of contaminated water.

What are the benefits?

- The unique design prevents backflow

- Passive non-mechanical operation and negligible maintenance and energy costs

- Easy installation on all existing infrastructure

- Resistant to corrosion, fire and abrasive (sludge) flows

- Very quiet operation without water hammer

- Won’t warp or freeze

- Proco Products, Inc. patented sloping bottom design eliminates standing water

- ANSI/NSF-61 material is suitable for drinking water

- Live marine life such as fish harvesting can pass through the valve unharmed

- Wide range of sizes, materials and connections available

- 35 to 50 years of service life