The company’s commitment to innovation was demonstrated with the presentation of the IZMSA flowmeter with TC 7520 certificate according to 2014/32/EU, and the announcement of a sales partnership for MicroMotion Coriolis mass flowmeters in Europe. These additions to the existing portfolio mark a significant expansion for Anderson-Negele, solidifying their position as one of the most comprehensive suppliers of hygienic process instrumentation specifically designed for the food and beverage industry. This marks an exciting step in the company’s continued growth and development.

Flow meters for the precise determination of quantity, volume or speed of media flowing into systems are the basis for safe and efficient processes in almost all applications in the food and beverage industry. Typical examples are:

- measurement of product reception

- accurate dosing when mixing beverages or dairy products

- supervision of lautering tun, brew kettle or other brewery processes

- recipe control for mixed or soft drinks

- monitoring CIP systems

- high-precision control of filling lines

Flow switches are used in almost all production plants to monitor the plant’s technical safety and the correct operation of the processes. Typical risks for process reliability which can be detected and signaled by flow switches are:

- a possible malfunction of a pump,

- a closed valve, or

- a misdirected medium.

With various technologies, Anderson-Negele flow sensors and flow switches offer a suitable measuring system for almost every application, every process, and every fluid:

- Magnetic-inductive flow meters for media with minimum conductivity >5 μS/cm

- Certifiable flow meters for installation in official measuring systems according to 2014/32/EU

- Turbine flow meters for all aqueous media, regardless of conductivity

- Ultrasonic flow switches for all media with turbidity > 1 NTU or particles > 50 μm

- Calorimetric flow switches for all aqueous media, even high-purity fluids, independent of conductivity

The inexpensive solution for almost any conventional application

As an inexpensive and compact all-rounder, the electromagnetic FMQ is a versatile, robust, and reliable flow meter. The performance is tailored to the needs of breweries, dairies, and other areas of the beverage industry. The optional digital IO-Link interface and the possible remote version round off the FMQ’s wide range of applications.

The specialist for filling, now also certifiable

The IZMSA electromagnetic flowmeter offers special functions for filling operations, such as quantity preselection control, self-monitoring with automatic fault diagnosis or separate temperature recording. The latest IZMSA version, unveiled at BrauBeviale, is a custody transfer device with Evaluation Certificate TC7520 for installation in official measuring systems according to 2014/32/EU.

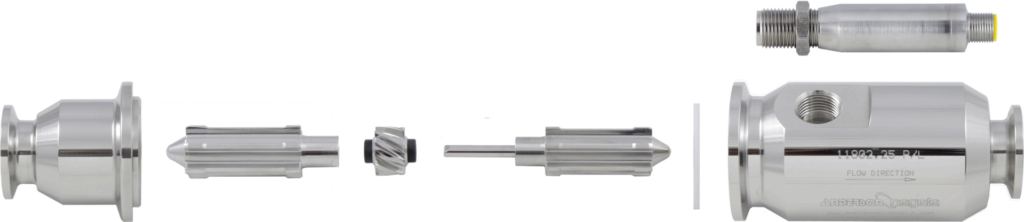

The solution for non-conductive media

Turbine flow meters with non-contact pulse measurement are the reliable, precise, and economical alternative to mass flow meters or magnetic-inductive flow meters. Featuring this measurement technology, the HM-E turbine flow meter is also suitable for non-conductive, aqueous media such as filtered fruit juice or beer, alcohols, condensate, light oils, salt solutions, cleaning media, and acids, but also process water, demineralized water, and WFI.

The reliable sentinels: Flow Switches

Not always a full-grown flow meter with highly accurate volume control it required to run a process reliably. Flow switches are primarily used to control costs by minimizing risks. If a medium does not flow in a process due to a system error, this can cause significant damage. Pumps may run dry, CIP processes may not run according to specifications, mixing, and filling processes may be disrupted, all of which can lead to high plant or product damage. With flow switches, such malfunctions are immediately detected, and countermeasures can be initiated. FWS/FWA and FTS flow monitors give an alarm when the flow stops and are ideal for monitoring pump systems, filters, cooling circuits, the CIP return or for detecting misdirected media. The FWA also offers the output of the flow velocity with approx. 10% accuracy, in many cases sufficient to spare more expensive flow meters.

Customization? No problem!

The constant further developments within the electromagnetic flow range include the available device options (such as IO-Link, official measuring device certification, remote versions or quantity specification), the technical performance data (such as measuring accuracy up to ± 0.2%) and the installation options (e.g. special adapter flanges for the replacement of third-party devices). With these, Anderson-Negele is constantly expanding its “Flow-How” for use in new plants, but also in particular for the uncomplicated replacement of existing sensors from its own production, from GEA-Diessel or from other manufacturers.

The One-Stop-Shop for hygienic process instrumentation

With the new solutions in the flow area, Anderson-Negele completes its portfolio as a beverage instrumentation supplier. The sensor technology developed in-house and produced in the company’s own factories now includes temperature, pressure, fill level, limit level, turbidity, conductivity, load cells, and also flow meters and flow monitors in multiple versions.