- Control Valve Leakage/Passing (For Metal Seated Valves)

- Galling/Seizure of the Valve Plug in a Cage

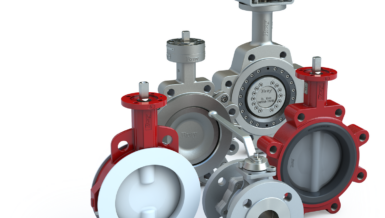

The MASCOT Control Valves take care of both these issues at a fundamental Design & Selection level.

Control Valve Leakage/Passing: Many argue that the job of a Control Valve isn’t to achieve a good shutoff and that sizing a Control Valve for Class V (Tight Shut-off) in fail condition increases Actuator Size and associated costs. We at MASCOT agree to both sides of this argument and have a solution that considers the merits of both sides. MASCOT counters this issue with two different solutions:

- Plug and Seat Contact: The MASCOT body Assemblies are so designed that the Seat is never Screwed in. It is instead always Clamped In providing easy removal for maintenance and also adds the capability of the seat to align itself to the Plug Center Line during Assembly. At the time of Assembly, the Valve is Stroked Shut which aligns the Plug and Seat, and only then the Body Bolting is fully tightened. This ensures alignment of Plug and Seat. Furthermore, the Plug and Seat are always just machined and never lapped which ensures line Contact. Again: the MASCOT Plug and Seat do not need any kind of Lapping. The MASCOT Globe Control Valves for this reason require very few shutoff forces.

- Actuator: Under normal condition when Instrument Air is present the MASCOT Control Valves offer Class V leakage (despite having been sized for Class IV leakage). This is due to the Double Spring Return Actuator Configuration. The MASCOT Actuators work as Double Acting Actuators when Instrument Air is present and as Single Acting Actuators when Instrument Air Fails. Under normal operation the Actuator shuts the Valve and the Plug and Seat make a line contact due to the self-centering and alignment of the Plug and Seat at the Assembly/Manufacturing Level. This ensures that the High Thrust of a Spring Cylinder Actuator is distributed over a lesser area of the Line Contact which ensures higher seat tightness than the competition.

Galling/Seizure of the Valve Plug in a Cage: Most Globe Control valve manufacturers offer “Balanced” design trims even for a standard service small size control valve. MASCOT’s approach is different. As MASCOT uses a Spring Cylinder Actuator which offers higher thrust capability compared to conventional Diaphragm Actuators, we have increased Stem Diameters for all our Control Valves sizes as compared to the competition and hence offer “Heavy Duty Top Guided Valves”. Again, due to the higher thrust Actuators, we do not “need” to offer Balanced valves to reduce Actuator size and hence we offer “Unbalanced” design trims for most sizes. This ensures that the Guiding is in a “Clean” area of the Bonnet and there is ample clearance between the MASCOT Cage and Plug that we call our Cages simply “Retainers” which perform the function of Retaining our Clamped in Seats.

Although unconventional the MASCOT Globe Valve design is simple and extremely easy to maintain. Contact your nearest Representative to know more about many more design advantages of a MASCOT Control Valve. MASCOT has a network of Representatives across the globe an experienced Application Team in India and the USA who can help solve your Control Valve needs quickly and effectively.