Compared to other open-close or control type valves, the characteristic properties of the rubber sleeve ensure that any accumulated material flows through again after opening the valve with as few parts as possible come into contact with the medium. The rubber sleeve absorbs the shock of abrasive material where other valves types are often damaged or jammed. The pinch valve is amazingly simple, safe, and durable. They close completely liquid- and gastight and in the open position, a completely round, straight flow is achieved.

How do Pinch Valves work?

Pinch valves use compressed air or fluid to open or close the valve. In the open position, the valve has no restrictions and allows a wide range of media to pass through the bore. The flexible internal rubber sleeve in the valve keeps the media isolated and prevents the risk of contamination.

Pinch valves are cost-effective, reliable, and easy to use, making them desirable in a very wide range of industrial applications. Many applications within the food and pharmaceutical industry, bulk material, and pneumatic transport, both wet and dry.

Pinch valves provide the following benefits:

- Easy maintenance

- Self-cleaning

- No dead volume

- Round straight flow in open position

- Eliminate scaling & clogging

- Minimal turbulence and friction

- Low maintenance costs

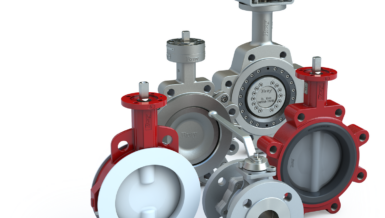

Hygienic & ATEX solutions

Hygienic solutions are particularly important in the food and pharmaceutical sectors. For this reason, pinch valves are manufactured with a control head in which all pneumatic and electrical components are integrated in one housing made of stainless steel and are splash-proof and easy to clean. The built-in manometer delivers additional control and shows what is happening on the inside of the valve. The part of the inner sleeve which comes in contact with the medium can be delivered in accordance with the FDA positive list.

Pinch valves are also suitable as fittings for ATEX areas because rubber sleeves with a conductive inner surface can be applied (R < 1.000.000 Ohm).

What are the possibilities?

Typical applications can be found in the entire food industry, from viticulture to bakeries, in animal feed production, in the chemical and pharmaceutical industry, in cement plants, drinking water, wastewater and process water areas, washing plants, cleaning systems, filter systems.

In addition to all standard products, it is possible to produce completely customer-specific valves

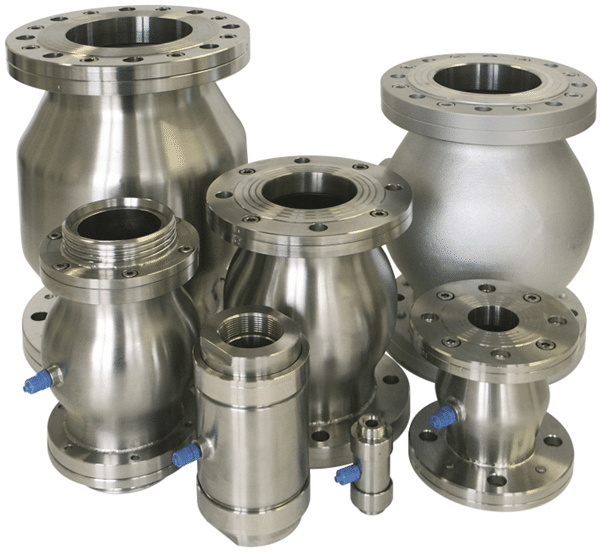

There are more than 5000 pinch valve variations regarding:

- Nominal size (DN 6 – DN 800)

- Connection type (flanged connection, threaded connections according to EN 10226-1 and EN ISO 228-1, DIN 11851 and DIN 11864-1 / DIN 11853-1

- Clamp connections according to DIN 32676 and DIN 11864 -3 / DIN 11853-3, nozzle / weld ends)

- Housing material (stainless steel, aluminum alloy, aluminum alloy with stainless steel cladding, polypropylene (PP), polyoxymethylene (POM)

- Rubber sleeve material in more than 20 material compositions (friction resistant, alkali and acid resistant, according to FDA, with and without fiber reinforcement)