Potassium hydroxide also known as KOH, or caustic potash is an electrolyte solution. This is a solution that conducts and there are three types of electrolyte solutions: strong acids, strong bases and salts.

During the production of hydrogen, water is split into hydrogen and oxygen using an electrolyte solution, in this case, potassium hydroxide. It conducts electricity between two electrodes in a cell – an anode and a cathode – enabling the reaction that generates hydrogen gas. The cells are usually assembled in series to produce more hydrogen and oxygen at the same time.

The potassium hydroxide and electrolyte transfer and recirculation pumps used by our client in this production process need, most importantly, to supply the high pressures required. In addition, the system needs reliable and corrosion-resistant pumps to circulate the electrolyte and ensure a smooth and consistent exchange of ions. This is why we specified high-pressure booster pumps.

The system could not operate at the designed pressures required for the process to operate effectively. Low system pressure can be caused by a variety of factories from a process reducing the system pressure by an amount greater than expected, system additions which were not factored into the original design or during system design to fine-tune outcomes.

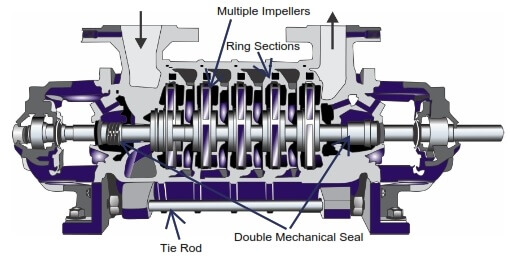

Booster pumps are usually multi-stage centrifugal pumps which are installed within the pipeline and designed to accept the high pressures within the existing system, and add to these by generating increased pressure and flow within a closed-loop system.

Multiple impellers within multistage pumps generate higher pressures than can be delivered with the use of a single impeller at maximum diameter. This is because impeller-side friction increases with size once it reaches a particular diameter. This in turn decreases pump efficiency. Therefore, to achieve higher pressures, it’s necessary to add several impellers along the same shaft in stages called ring sections. Each stage consists of an impeller and a diffuser.

When these extra impeller stages are added the flow rate is not changed, but the total head and shaft power increases proportionally to the number of stages. In short, multi-stage pumps are highly efficient, and what’s more, multiple duty points can be achieved by using variable speed drives and multiple outlets on the same pump.

What was our solution?

Here at North Ridge Pumps, we’re not tied to a single pump technology, so we can specify the best pump for a particular application – at the lowest lifetime cost. Indeed, we use our expertise to offer a bespoke solution, not something off the shelf.

For this particular project, we manufactured three multi-stage booster pumps in AISI 316 stainless steel.

AISI 316 and AISI 316L are stainless, austenitic chromium-nickel-molybdenum steels which have good resistance to non-oxidising acids and chlorine-containing media. Due to the chemical composition, both 316 and 316L are inherently resistant to corrosion as this brief from our client required.

What’s more, the potassium hydroxide pumps were specifically designed to handle electrolyte in a plant where the system pressure needed was in excess of 30 bar, with our pumps handling an inlet pressure of up to 37 bar.

Due to the high inlet pressures our pumps were built in a design variant containing a thrust bearing which is an additional highly performing bearing housing at the opposite end to the motor designed to balance the high radial loads and pressures within the pumps at intense duties.

The three pumps were assembled with ATEX IP66 motors and non-sparking brass coupling guards. They were supplied to the customer within 14 weeks of order.