This case study explains the installation of Cowan’s Zero Emission ESD Valve Actuator system at a midstream pipeline in Canada.

A Midstream services provider located in Canada has a number of API emergency shut down valves in their midstream pipeline distribution network in southern Ontario. Due to the geography of the territory, these valves are located in remote locations where conventional sources of energy are not available to automate these valves.

It is critical for the safe operation of the process that such valves are capable of shutting down the line when anomalies in the pressure of the gas passing through the pipe occur.

Initially, the company used hydraulic valve actuators with a manually operated hydraulic unit. These valves were left normally open. In the event the line pressure dropped or spiked, the system would use stored pressurized hydraulic fluid to close the valve as an emergency shutdown.

The system was provided and installed. However, it presented a number of issues that made the operation of these, highly critical valves, very inefficient. The main problem was the system would not hold the valves open for more than approximately 2-3 days due to internal leakage in the hydraulic system.

The actuators would start to drift and prematurely close the valve. This meant that operators had to physically go to these remote locations every 2 days to recharge the system and fully open the valve again.

It is crucial to these operators that the valves do not suddenly close during normal operation and disrupt the flow throughout these midstream pipeline distribution networks. The user sought assistance from our customer after being unable to find a proper solution from the supplier of the original system.

The Challenges

Our customer contacted us looking for solutions. Our Engineering Team got to work tackling the problem. Within the challenges was not only the lack of conventional energy but also the amount of force the valves needed to stroke, making other systems such as solar power not a viable solution.

Another main concern for the customer was that any automation replacement had to be a drop-in retrofit which added an extra layer of complexity to the challenge, as it was not possible to remove the valve from the pipeline.

Understanding these issues, Cowan’s team engineered a solution within the capabilities of a hydraulic system that would be designed to be a drop-in replacement, maintain the valve open for no less than 7 days while keeping the needed fail-safe energy available for any emergency shutdown events.

The Solution

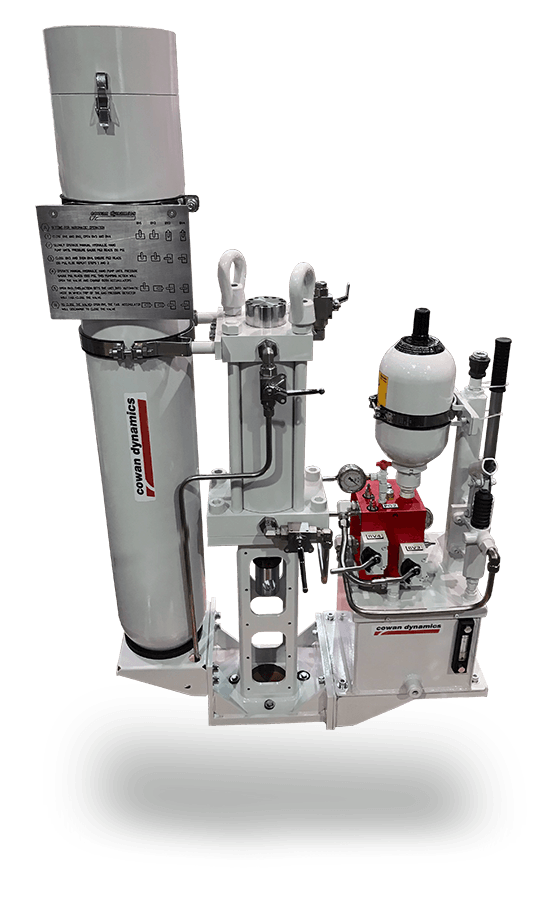

In constant collaboration with our customer to ensure that throughout the design process our Engineering Team kept the needs of the applications and operations in mind, Cowan Dynamics developed a self-contained, plug-and-play hydraulic actuator and actuation system designed to be retrofitted to the valve while inline and to hold the system pressure for a minimum 7 days while keeping the valve locked in place during normal operation.

The complete solution consisted of a hydraulic accumulator, a 3000 PSIG rated actuator from Cowan’s series ML and a specially designed hydraulic manifold completed with a reservoir, a leakage compensating small accumulator and a hand pump that serves as a power source to pressurize the accumulator and actuate the valve. The hydraulic circuit design reduces significantly pressure drops in the system due to thermal expansion or leakage through hydraulic components.

The Results

After 2 weeks of functional testing performed by our product development team, it was proven that the unique design of the hydraulic circuit far exceeded the original 7 day target. After 12 days of testing the systems only experienced a drop in the main pressure of 3%. This can be seen in the test results:

After such a successful test result, the Research and Development team at Cowan Dynamics started a project to standardize the design of the system. The ZE-ESD module is a great solution for customers with midstream pipeline distribution networks.

For installations where their critical API emergency shut down valves do not have access to conventional power and they need a fugitive emission-free actuation solution.

“Thank you to Cowan Dynamics for listening, to understand and not just sell.” – Jamie Kells, Everest Automation, Valve Subject Material Expert