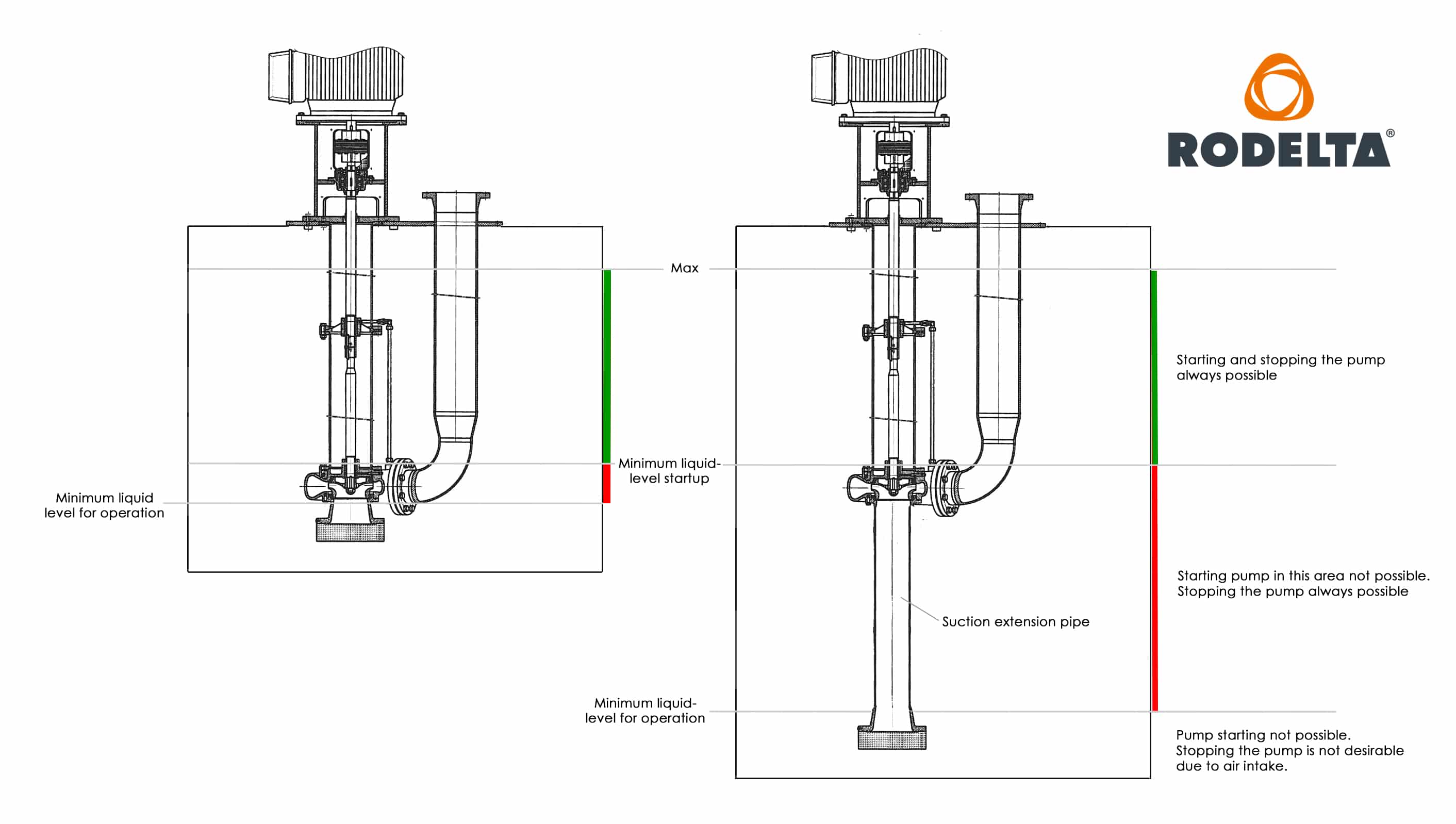

Longer pumping is technically unwise because the liquid coverage will become too small, which causes the pump to draw air whirls. This has an adverse effect on the life time of the impeller.

As soon as the liquid level is below the impeller at the suction extension and the pump is switched off the pump will no longer be primed, the liquid flows away and the impeller becomes dry. The pump can no longer be started in this area.

The liquid level for pump operation is also limited by cavitation. When the liquid level drops, the pressure at the impeller inlet and thus the NPSHa decreases. When the margin between NPSHa and NPSHr becomes too small, cavitation erosion will damage the impeller and operating the pump is not recommended. The pump can be started again when the impeller is primed. (Above minimum liquid level for start-up.) Suction extensions of 5 meters are possible in many cases, depending on the operating conditions.

Suction pipe extension can also lead to cost savings. The cost savings can be significant, especially with expensive material versions such as duplex and super duplex. Extending the suction pipe can lead to fewer shafts and shaft bearings being required. However, the operating conditions in the system must allow this. By applying suction pipe extension, the advantages of vertical immersible sump pumps can also be used with deeper pump basements or liquid tanks.